Feed granulation device

A granulation equipment and feed technology, applied in feed, food science, application, etc., can solve the problems of low production efficiency, easy to break up, and insufficient compaction of granules, and achieve the goal of improving production efficiency and drying efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

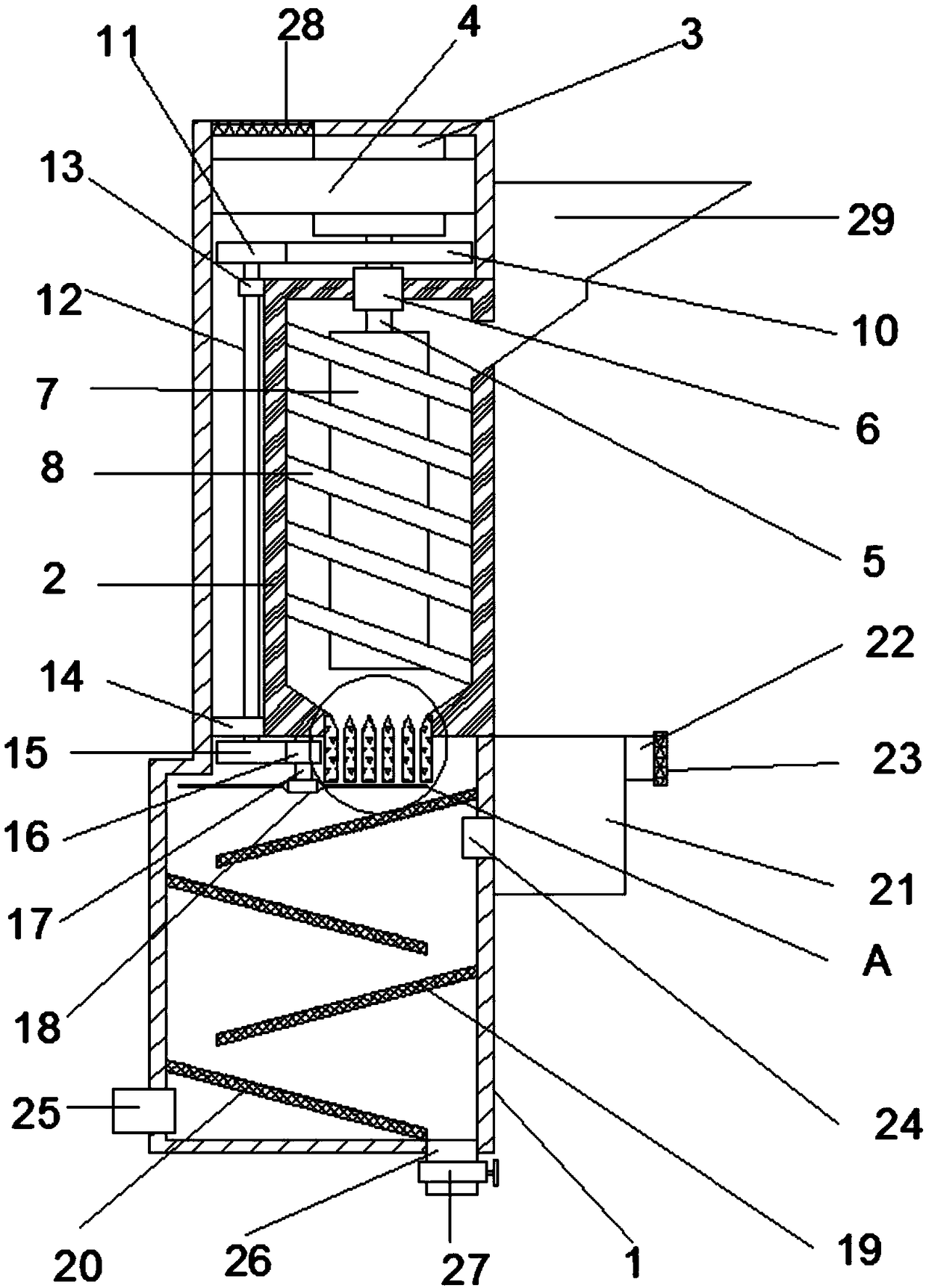

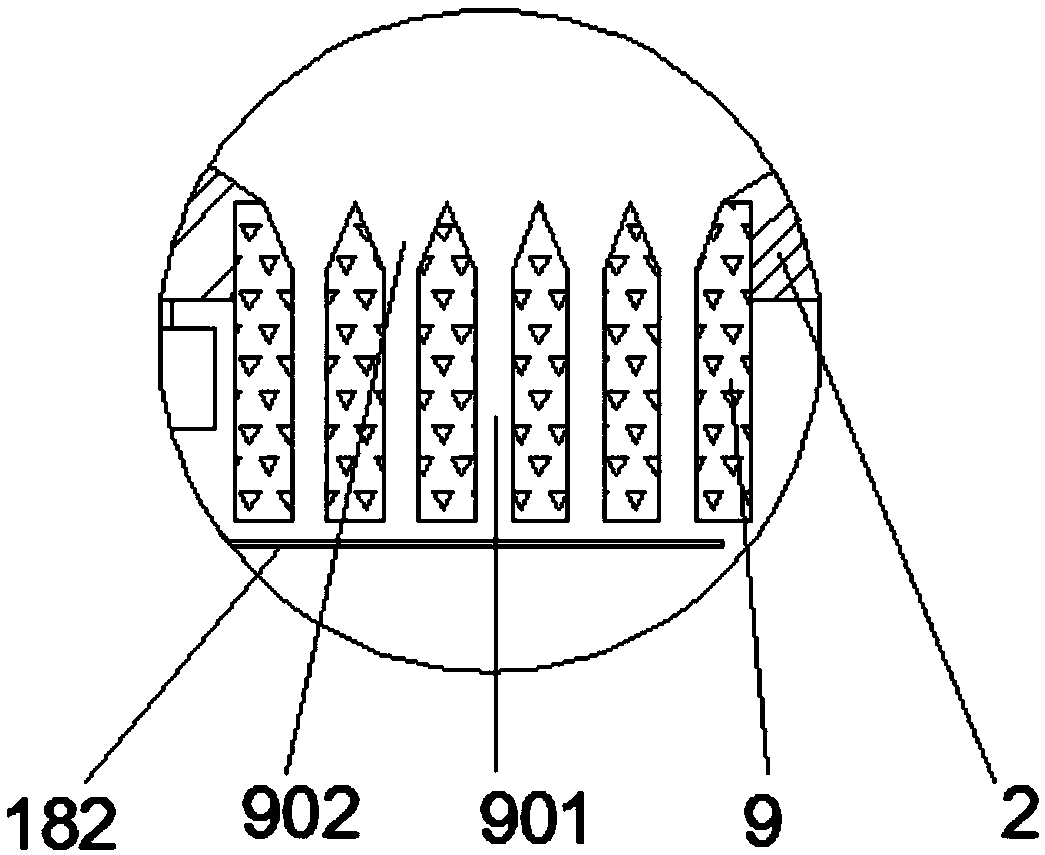

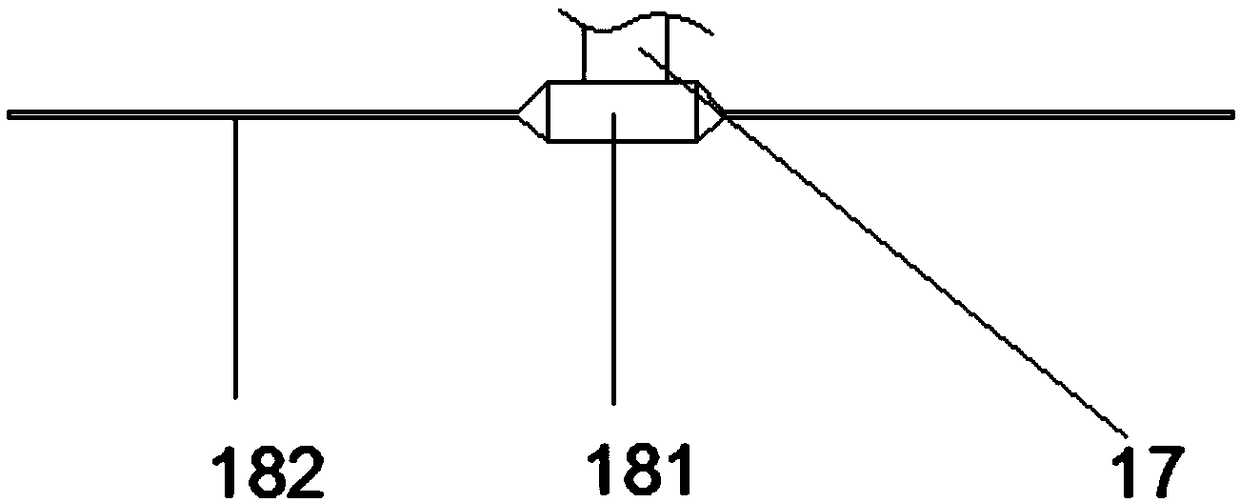

[0020] Such as Figure 1-Figure 3 As shown, a kind of feed granulation equipment proposed by the present invention includes a casing 1, a pressurized box 2, a motor 3, a molded part 9 and a hot air blower 21, and the upper part of the casing 1 is provided with a pressurized box 2. A motor 3 is provided on the side, and the motor 3 is fixedly connected to the inner side wall of the housing 1 through the first fixing bracket 4. The lower end of the motor 3 is provided with a first rotating shaft 5, and the lower end of the first rotating shaft 5 runs through the top of the pressurized box 2 and is connected to the runner column 7. A compression spiral disc 8 is arranged on the outer side of the runner column 7, and the compression spiral disc 8 is rotationally connected with the inner wall of the pressurized box 2, and the inner bottom of the pressurized box 2 is set as a slope structure, and the lower end of the slope structure is connected to the formed part 9, and the formed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com