Technology for continuously producing RFID tag antenna in rolling manner

An RFID tag and antenna technology, applied in the field of non-contact automatic identification, can solve the problems of high overall process cost, involving highly corrosive and highly toxic chemicals, and high process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

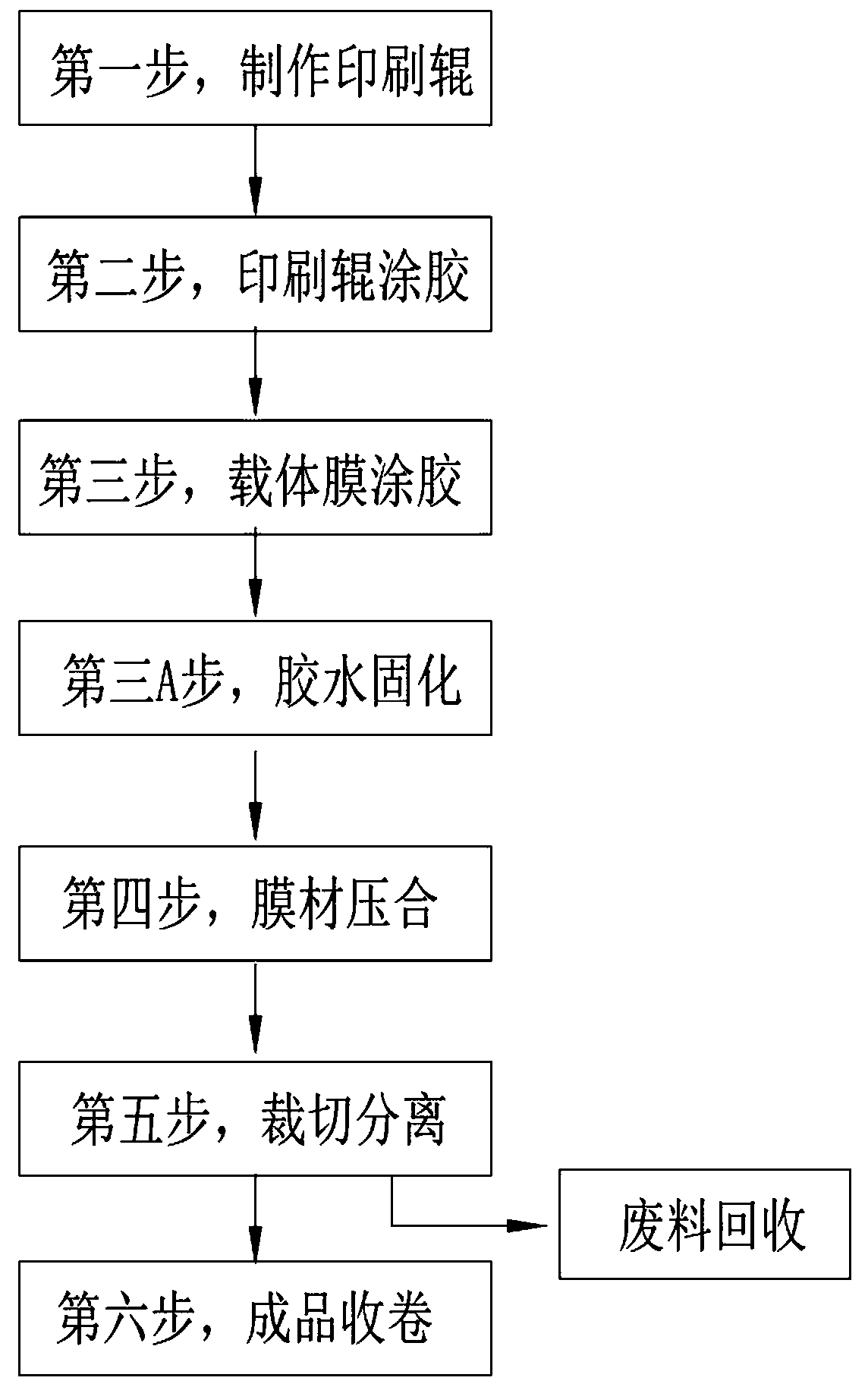

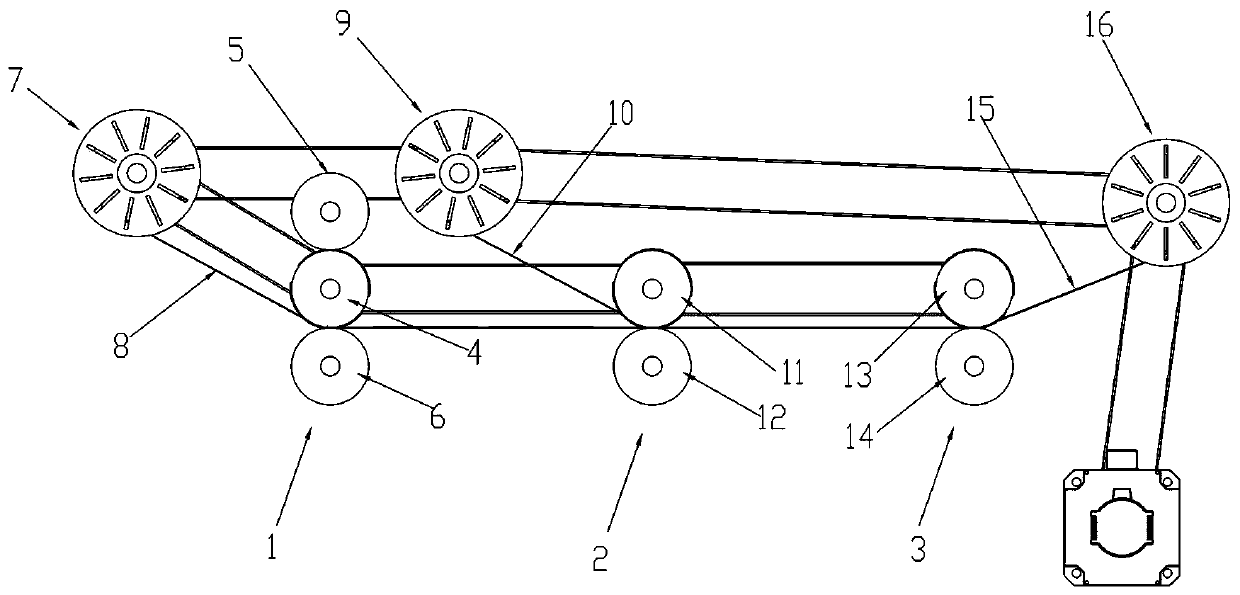

[0025] In this embodiment, refer to figure 1 and figure 2 , the process for the continuous production of RFID tag antennas in a rolling manner for its specific implementation includes the following steps:

[0026] The first step is to make printing rollers. On the surface of the printing rollers 4, more than two groups of antenna modules are evenly arranged, and the shape of the antenna modules is the same as that of the RFID tag antenna 15 to be produced.

[0027] In the second step, the printing roller is coated with glue, and the printing roller 4 is driven to rotate by the motor transmission assembly, and the gluing mechanism is used to apply glue to the rotating printing roller 4, so that the surface of the antenna module is evenly coated with cured glue. The gluing mechanism includes a glue storage barrel, a rubber scraper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com