Fully-automatic rope head welding device

A fully automatic and welding technology, applied in the field of injection molding parts production, can solve the problems of large labor costs and production resources, low production efficiency, hidden dangers of production safety, etc., to eliminate long-term contact, realize automatic control, and achieve high product standard accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing of description:

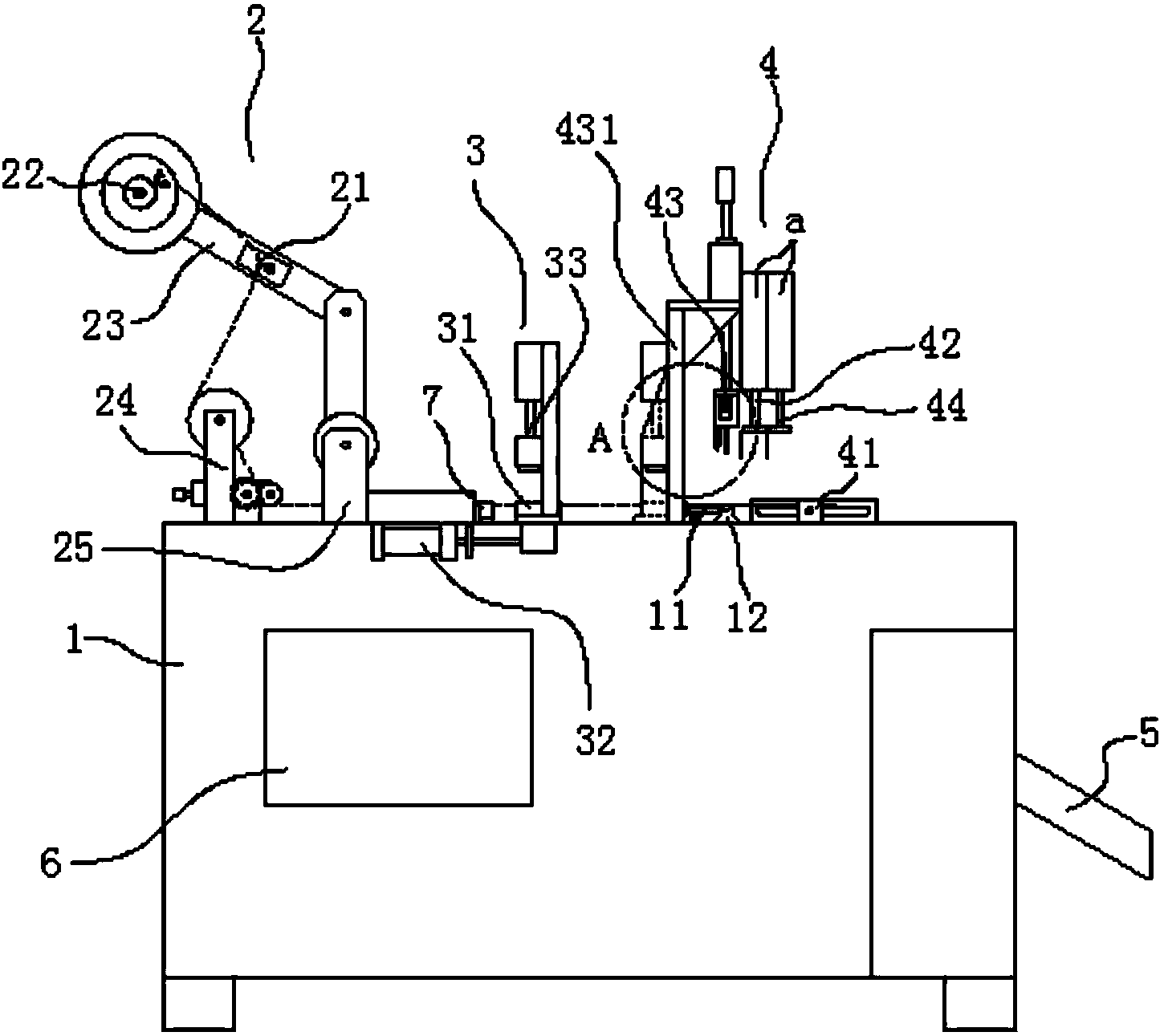

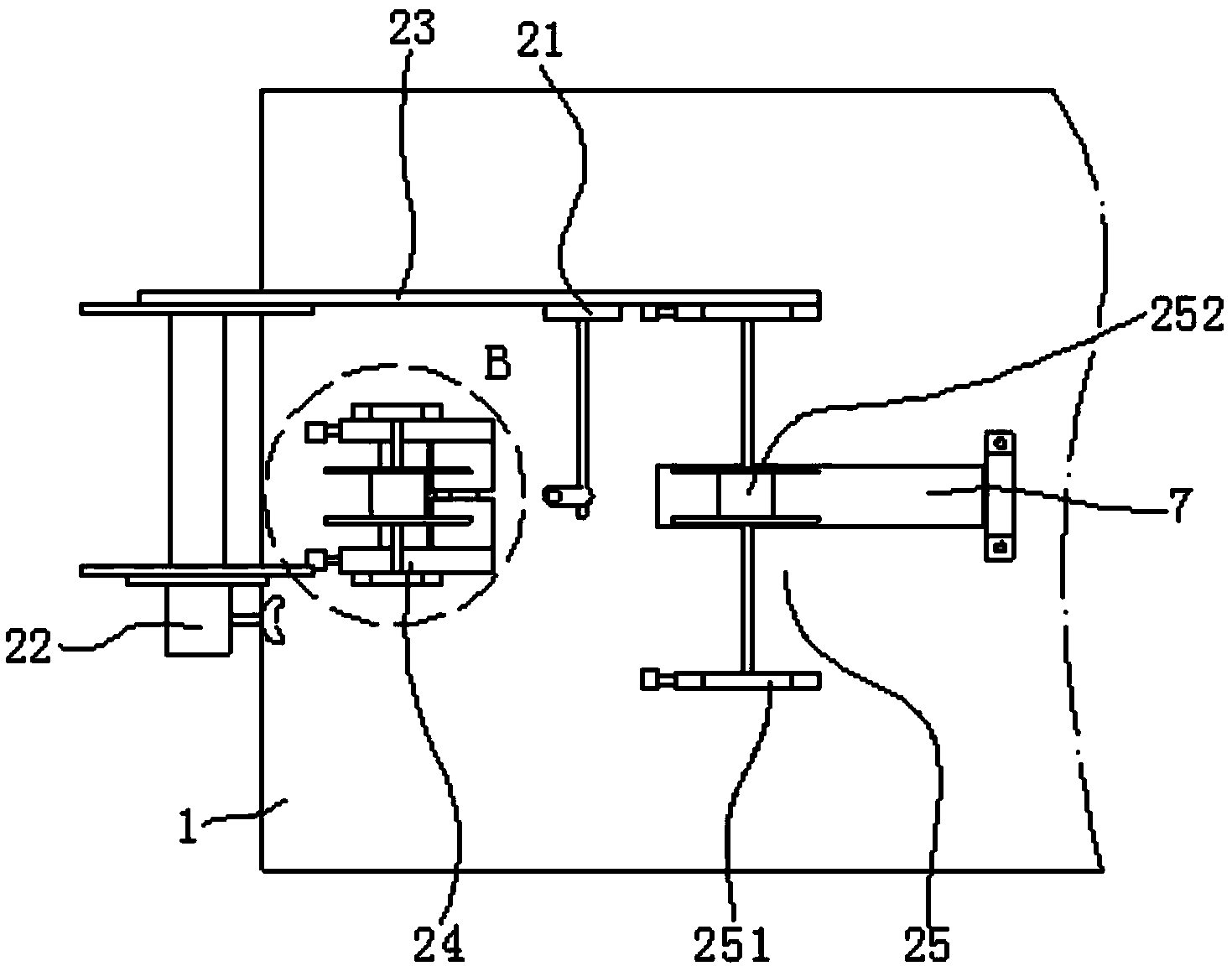

[0033] Such as Figure 1-6 As shown, the present invention relates to a fully automatic rope head welding device, which includes a bed 1 with a built-in micro-control center 6, on which a feeding shaping mechanism 2 and a delivery mechanism 3 are sequentially installed from left to right , the fusion forming mechanism 4 and the storage part 5 .

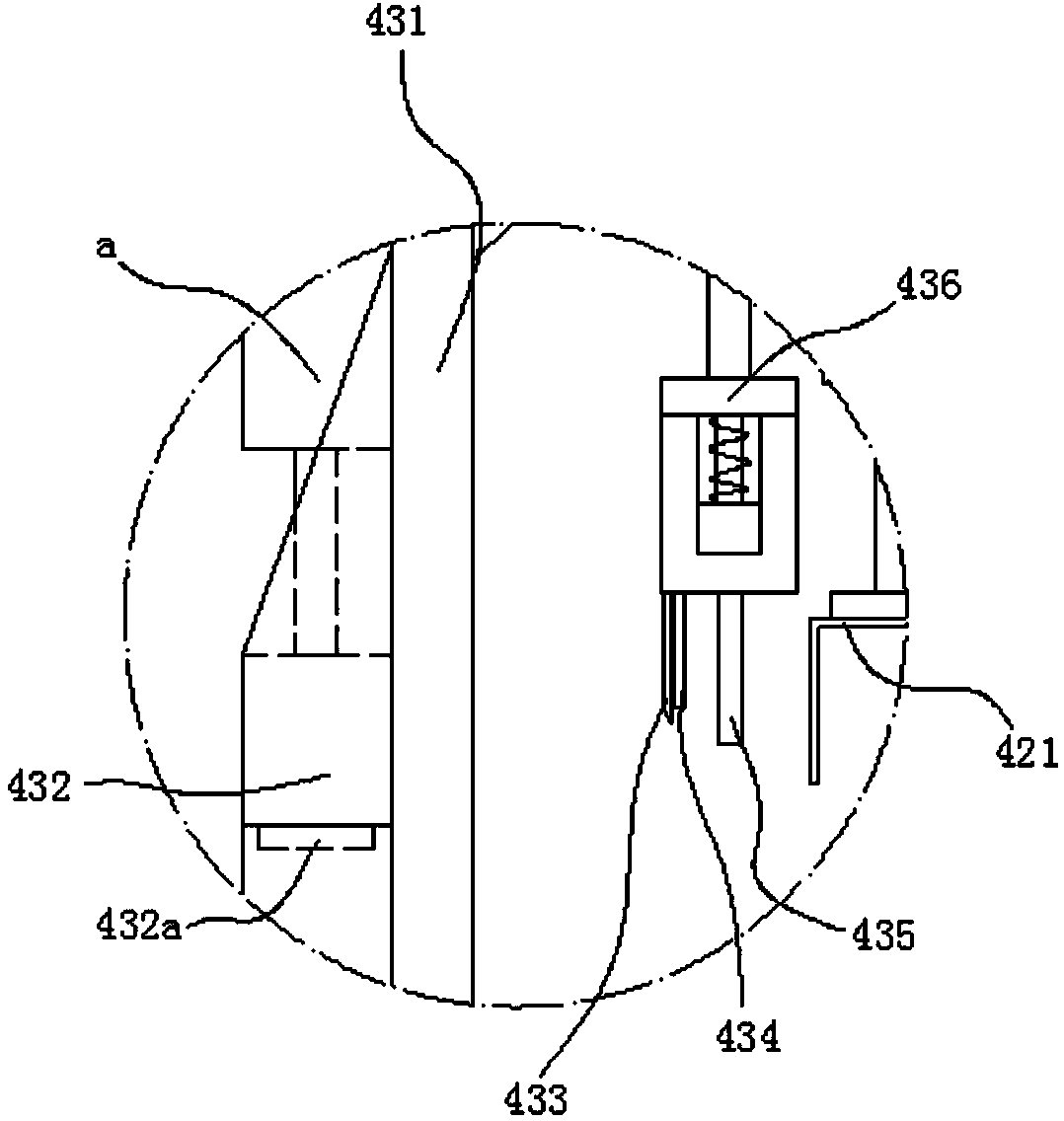

[0034] Such as figure 1 , 3 , 5, the discharging shaping mechanism 2 is provided with a knot braking part 21, which prevents the rope from knotting during transmission and affects product quality, and a material shortage mechanism is provided between the discharging shaping mechanism 2 and the delivery mechanism 3. The moving part 7 avoids the waste of electricity caused by the equipment being in the working state when there is a lack of material. The bending part 42, the welding and cutting part 43 arranged on o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com