Transportation feeding frame with directional conveying device

A transmission device and transmission rack technology, which is applied in transportation and packaging, thin material handling, winding strips, etc., can solve problems such as easy to produce defective products, time-consuming and labor-intensive, etc., to improve tire quality, determine the length accurately, and meet the technical requirements required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples.

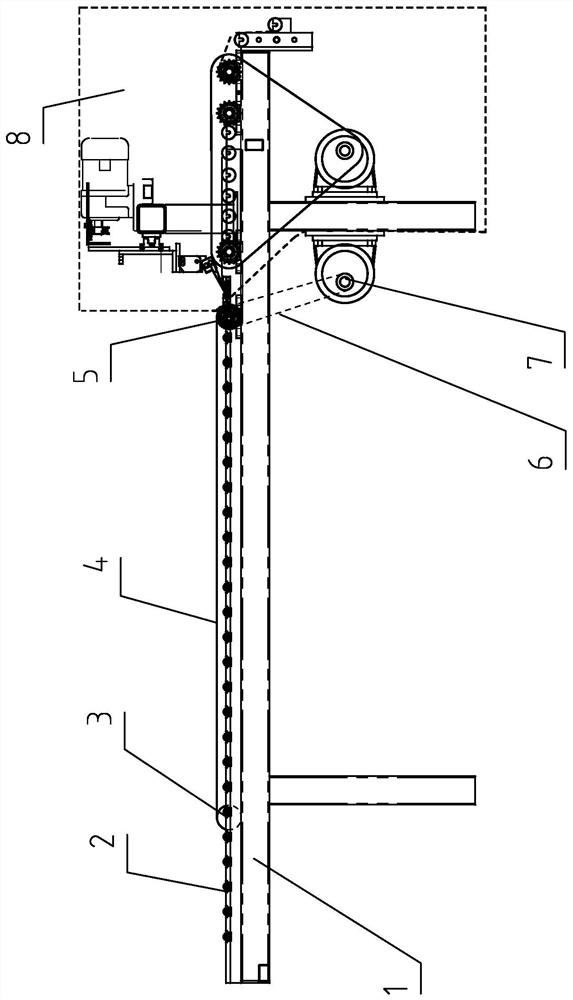

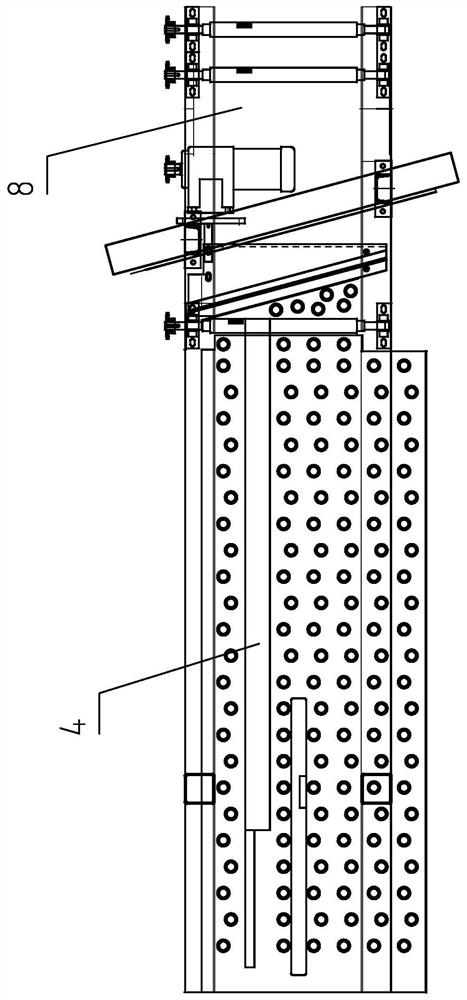

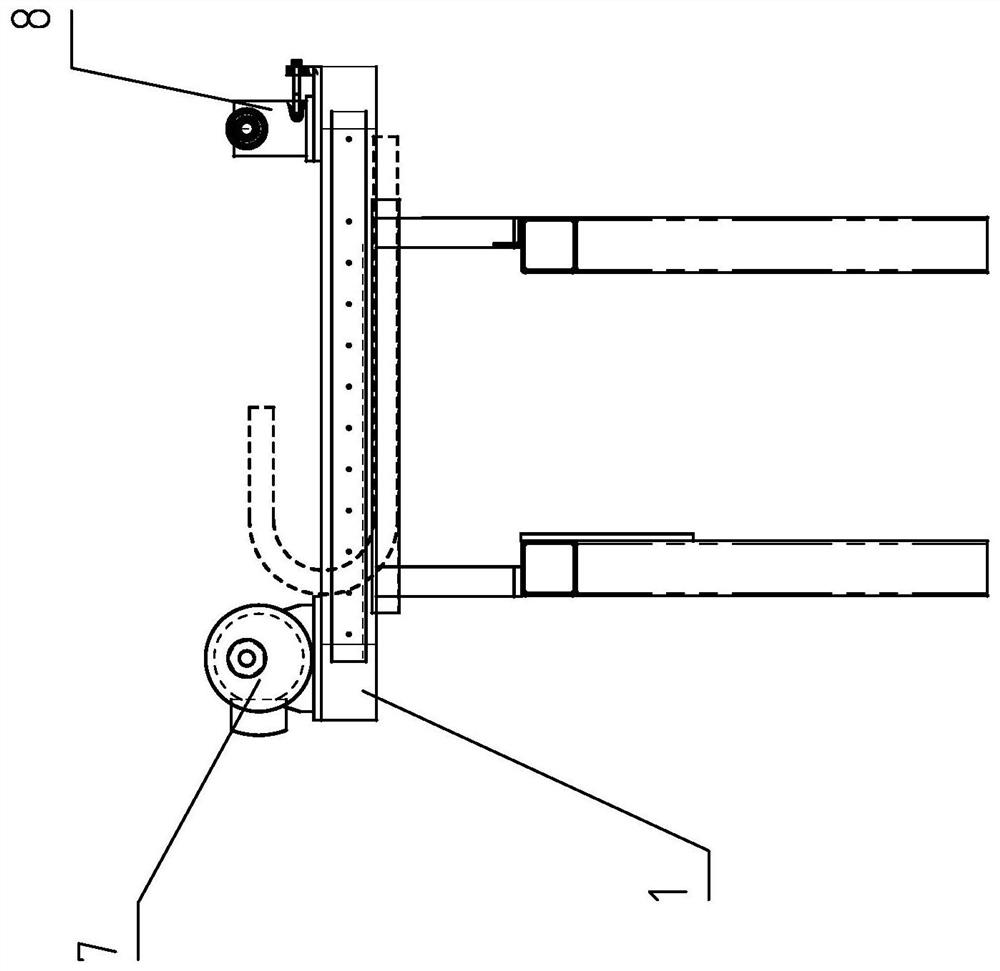

[0020] Such as Figure 1-3 As shown, a transport feeding frame with a directional transmission device is provided with a transmission frame, a transmission plate is provided on the transmission frame, a transmission drive device is also provided on the transmission frame, and a transmission drive device is provided on the transmission drive device. There is a directional conveyor belt, and the sidewall materials can be conveyed in a directional way, which eliminates the waste caused by inaccurate length fixing and stacking, and improves the quality of the tire.

[0021] The other end of the directional conveyor belt is provided with a driven roller, the driven roller is installed on the transmission frame, and the forming machine guide device is also provided on the transmission frame, and the forming machine guide device is arranged on the transmission frame Power roller end. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com