Flexible length-fixing method and device for tire preloading belt

A pre-installed belt and pre-installed technology, applied in metal processing and other directions, to achieve good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below with reference to the embodiments shown in the accompanying drawings.

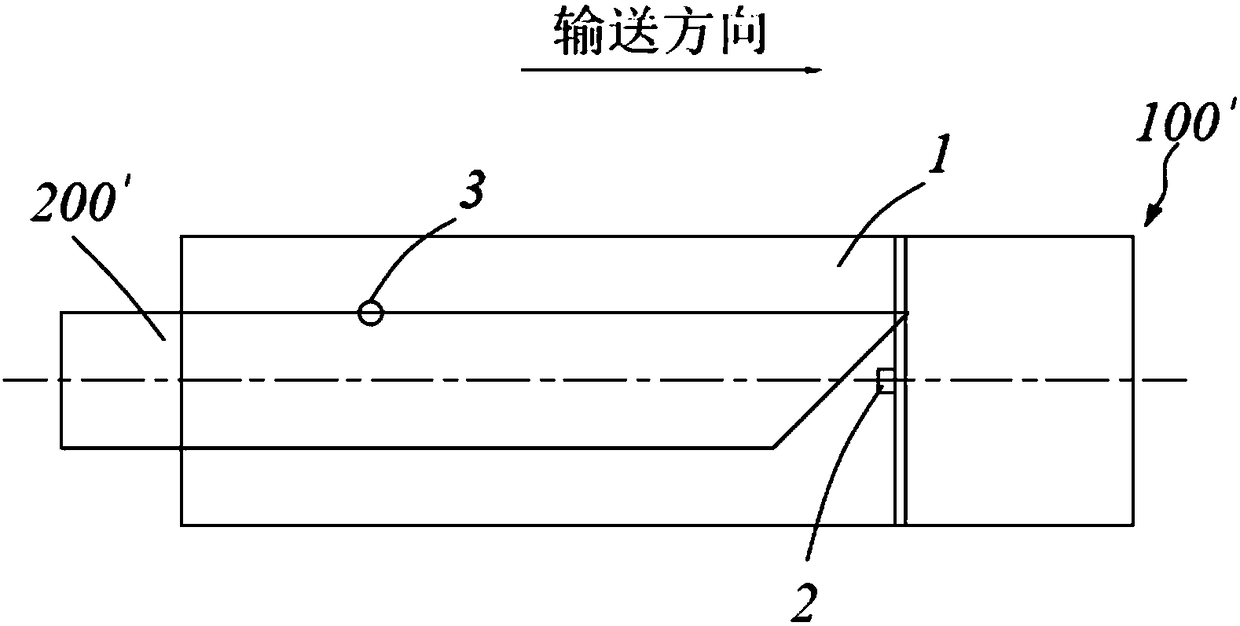

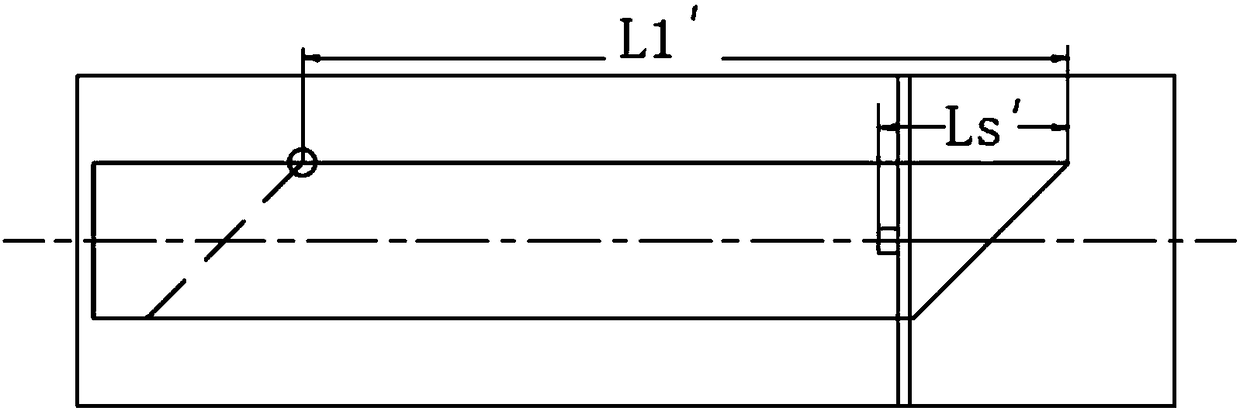

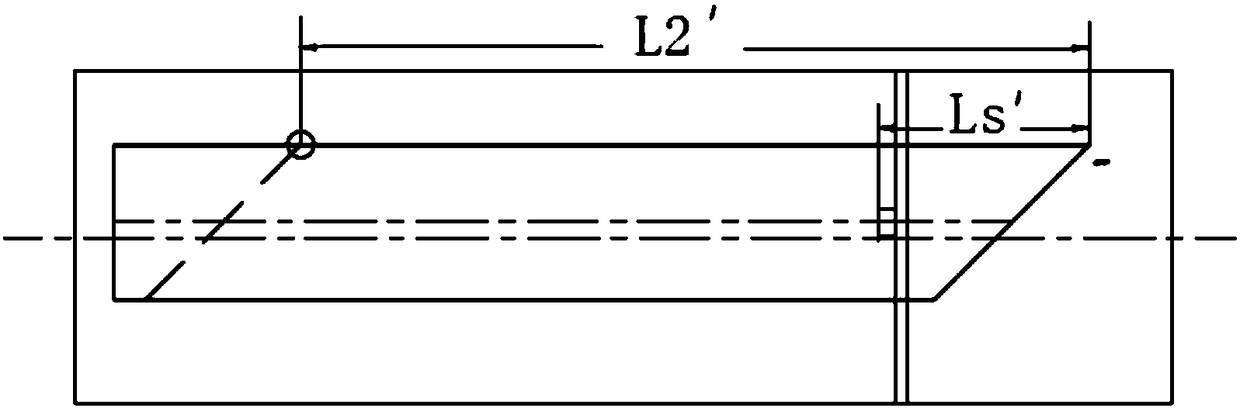

[0039] See Figure 4 to Figure 13As shown, the present invention relates to a tire pre-installation belt flexible length-fixing device 100, which is used to cut the tire pre-installation belt 200 in the conveying process to a fixed length. , a detection module 30 and a control module (not labeled). The conveying device 10 includes a first conveying assembly 11 , a second conveying assembly 12 and an interval groove 13 arranged between the first conveying assembly 11 and the second conveying assembly 12 . The first conveying assembly 11 conveys the preloaded tape 200 to the second conveying assembly 12 across the interval groove 13 . The first conveying assembly 11 and the second conveying assembly 12 respectively comprise a first conveying platform 111 and a second conveying platform 121, and the preloaded belt 200 is conveyed from the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com