A kind of production technology of prefabricated wall panel

A production process and assembly technology, used in manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve problems affecting production efficiency and quality, and achieve the effect of compacting concrete, expanding the scope of use, and improving use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

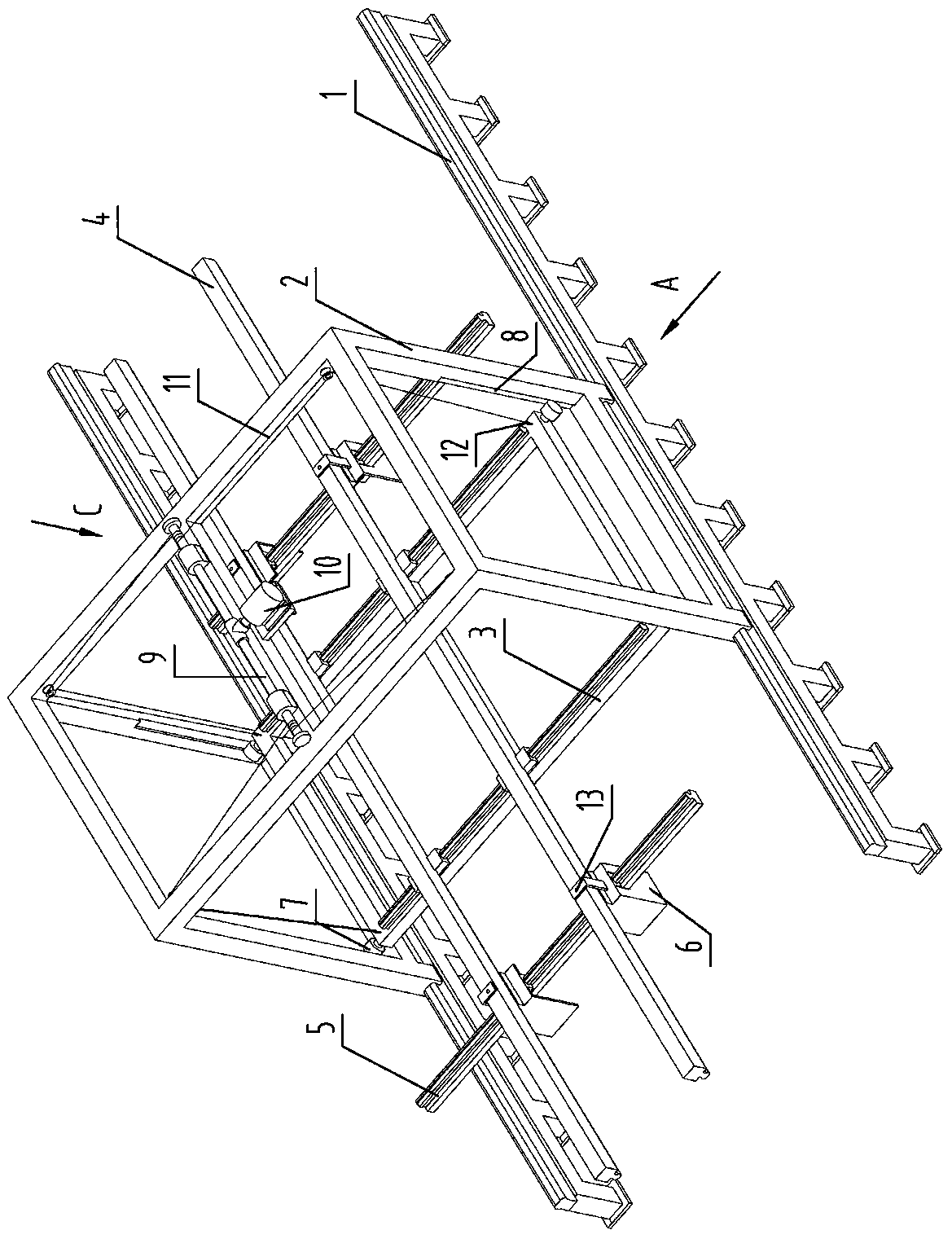

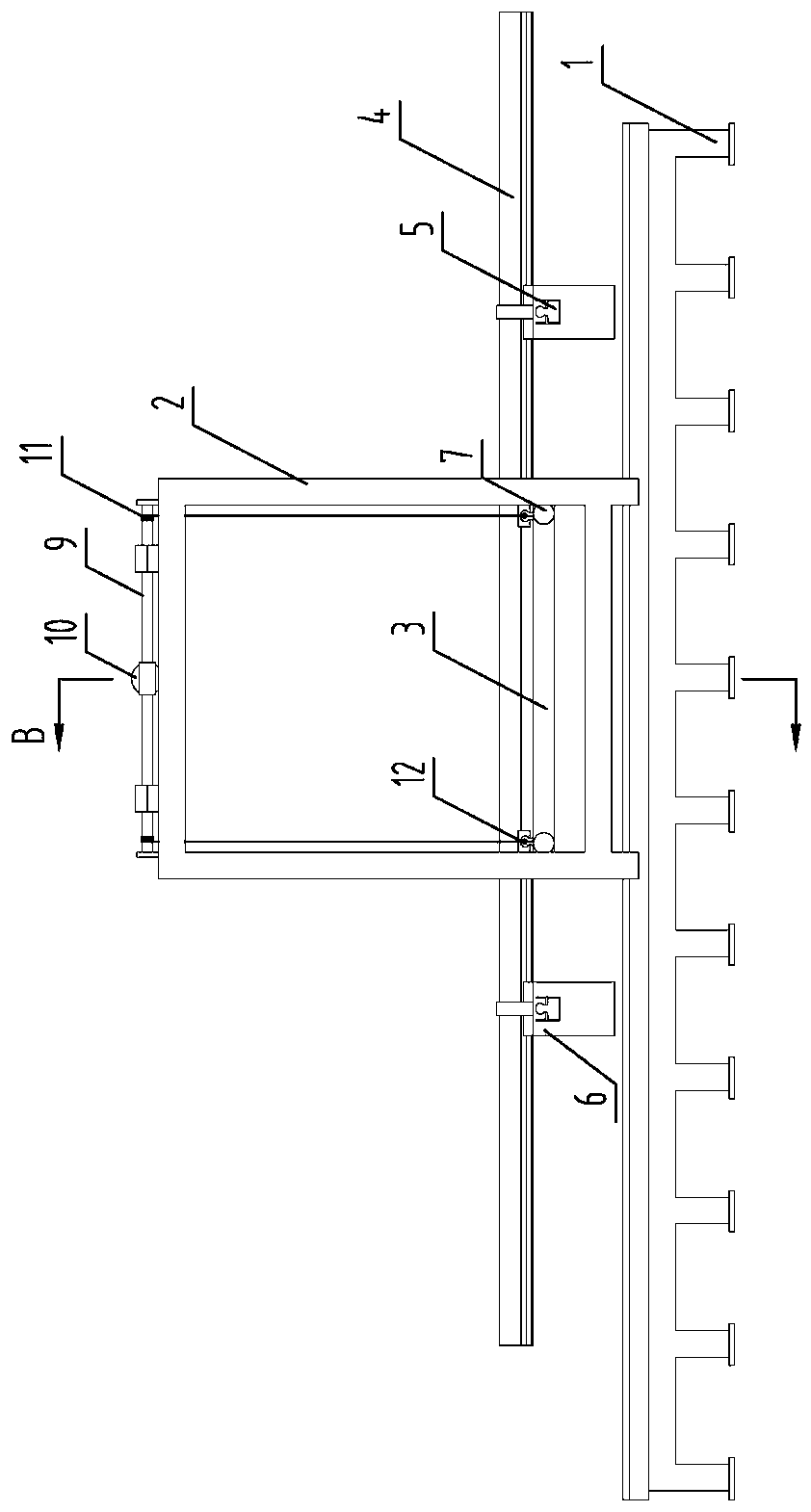

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0053]The present invention refers to the respective moving directions of the wallboard production line and the lifting frame 3, and defines the direction consistent with the moving direction as the longitudinal direction, and correspondingly defines the direction perpendicular to the moving direction as the horizontal direction; The side is defined as the inner side, and the other side away from the center of the precast wall panel is defined as the outer side accordingly.

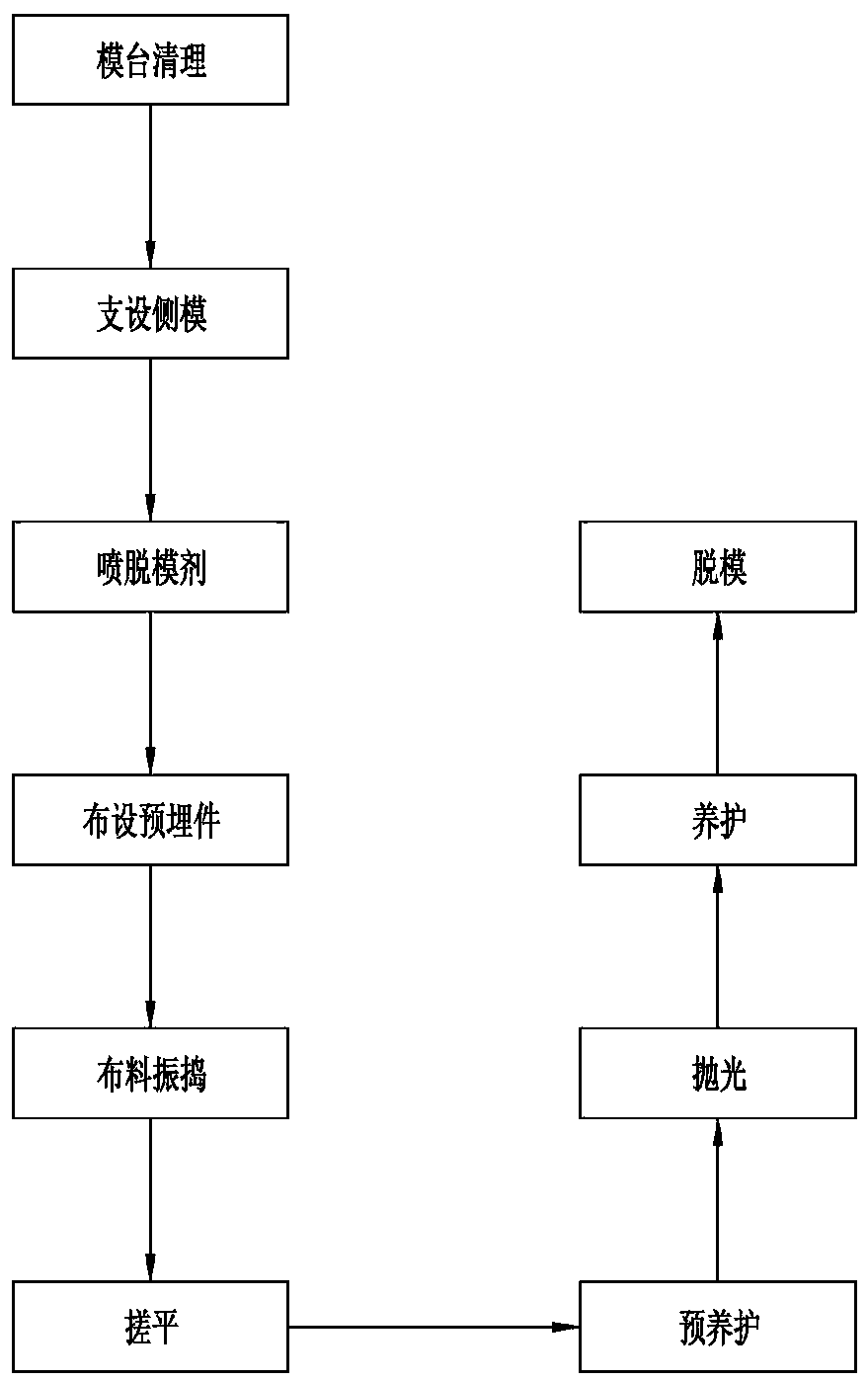

[0054] like figure 1 Shown, the concrete steps of the present invention's production assembly type wallboard are as follows:

[0055] (1) Mold table cleaning: Clean up the residues on the working surface of the mold table to make the working surface of the mold table clean;

[0056] (2) Support side formwork: the cleaned formwork table is conveyed forward along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com