Method for determining length of film by thermally stretching film

A technology of thermal stretching and thin film, which is applied in printing, rotary printing machine, printing machine, etc., can solve the problems of insecurity, film deformation, positioning and printing loss, etc., and achieve the effect of simple structure, preventing breakage and preventing control confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

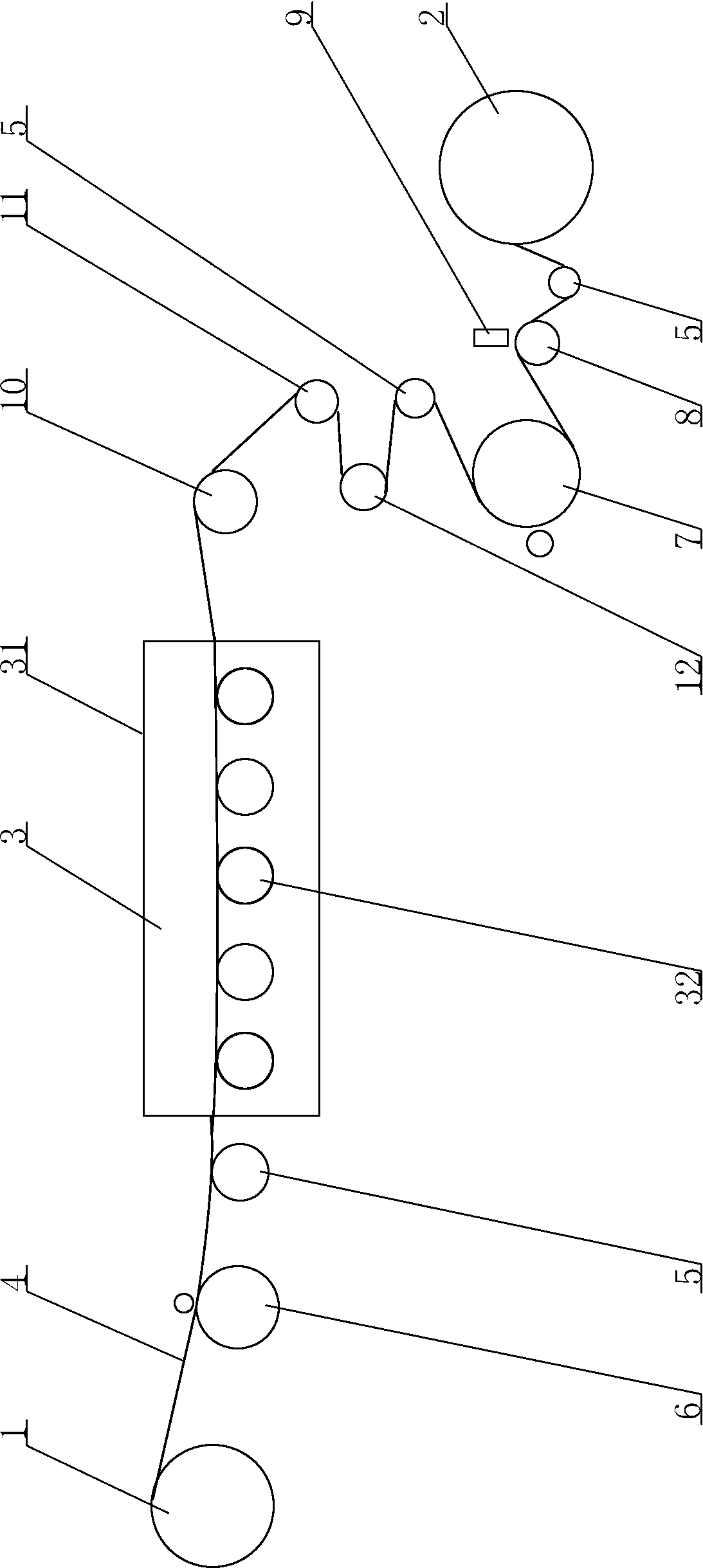

[0023] In order to better adopt the film thermal expansion and fixed length method of the present invention to stretch and fix the film, the film thermal expansion and fixed length device as shown in the accompanying drawing is adopted, and the device includes: an unwinding device 1 and a winding device 2 , a heating device 3, a support roller 5 arranged in the traveling direction of the film 4, a control system, a first traction roller 6, a second traction roller 7, a length measuring roller 8, a photoelectric eye 9, a tension fine-tuning mechanism and an ironing roller 10; The first traction roller 6 is located at the place ahead of the heating device 3, and the second traction roller 7 is located at the rear of the heating device 3; the driving motors of the first traction roller 6 and the second traction roller 7 are electrically connected with the control system respectively; the unwinding device 1 is arranged in front of the first traction roller 6, and the winding device...

Embodiment 2

[0033] In the case that other parts are all the same as in Embodiment 1, the difference is that: in step (1), the oven 31 heats the film 4 to 180°C; in step (2), the first pulling roller 6 and the second pulling roller 7 The tension applied to the film 4 was 0.1N.

[0034] Embodiment two

[0035] In the case that other parts are all the same as in Embodiment 1, the difference is that: in step (1), the oven 31 heats the film 4 to 105°C; in step (2), the first pulling roller 6 and the second pulling roller 7 The tension applied to the film 4 was 75N.

[0036] In other embodiments, the oven may be replaced with multiple heated rolls.

[0037] In other embodiments, a cooling roll may be arranged behind the second pulling roll to cool the film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com