mold for prefabricated concrete

A prefabricated component and concrete technology, applied in the directions of molds, manufacturing tools, mold auxiliary parts, etc., can solve the problems of difficult fixing of steel bars, difficult separation of molds, etc., to facilitate handling and installation, reduce weight and production costs, and evenly stretch the length of steel bars. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

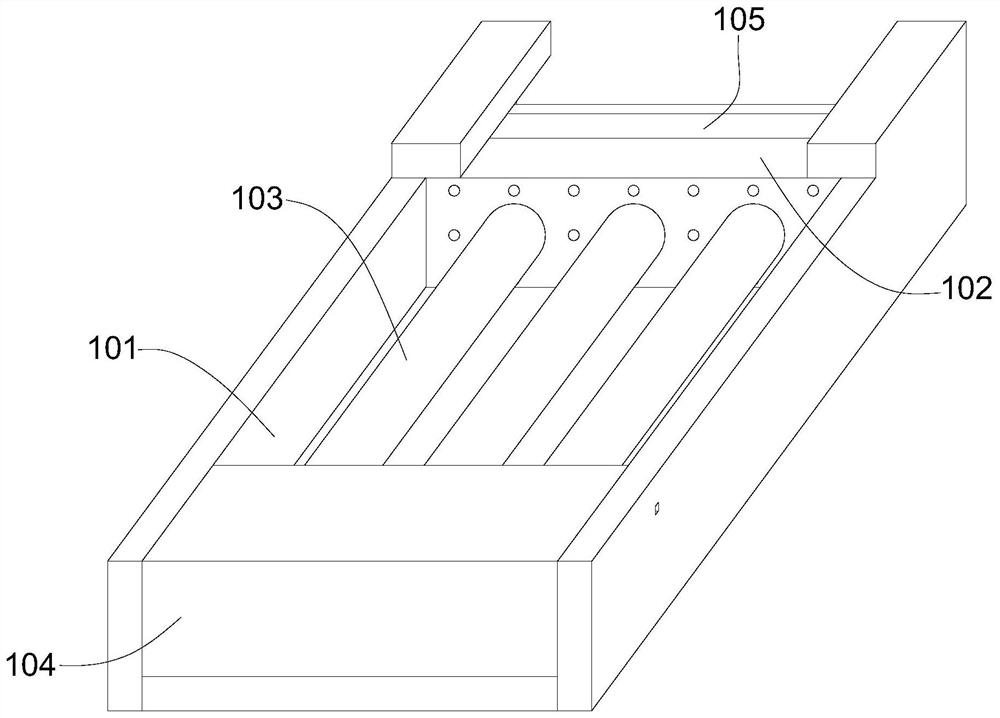

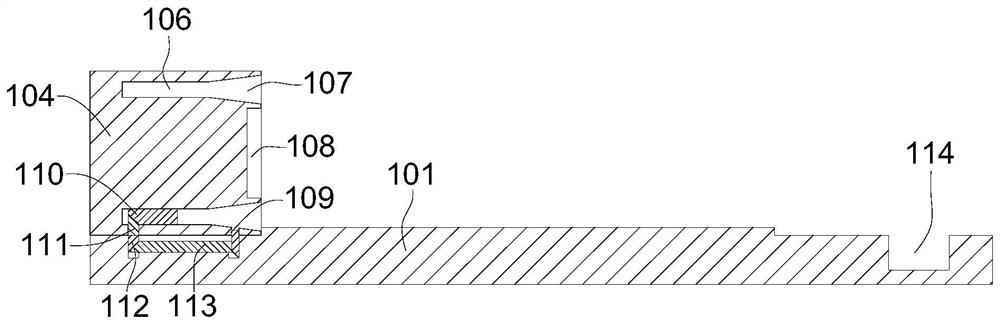

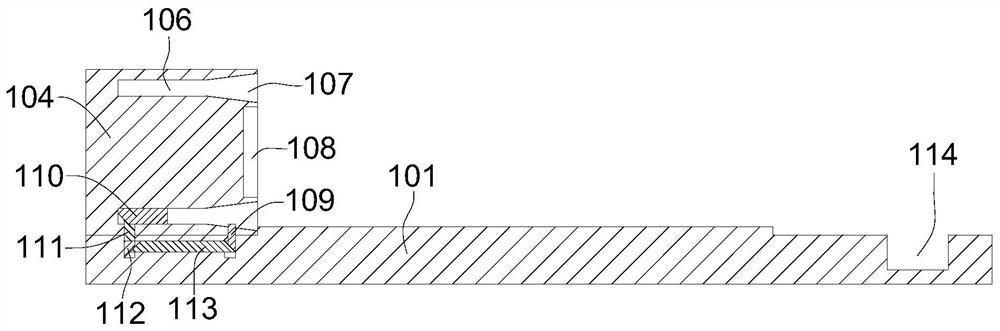

[0063] refer to Figure 1 to Figure 9 , the concrete precast component mold disclosed in the embodiment of the present invention, which includes a main body 101 , a first slider 102 , a second slider 104 , an auxiliary connector 130 , a fixing block 105 and a plurality of connecting rods 103 .

[0064] The main body 101 includes a bottom plate 117 and two opposite side plates 118, the bottom plate 117 and the two side plates 118 enclose a receiving groove 119; the first slider 102 is detachably engaged with the first end of the receiving groove 119, and the A slider 102 is slidably connected to the bottom plate 117, and the first slider 102 slides relative to the bottom plate 117 along the length direction of the receiving groove 119. The first slider 102 is provided with a plurality of first mounting holes 124, and the plurality of first mounting holes 124 are arranged at intervals; a plurality of connecting rods 103 are installed on the first slider 102, and the connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com