Heating device

A heating device and heating tank technology, applied in textiles and papermaking, etc., to achieve the effect of favorable space utilization and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

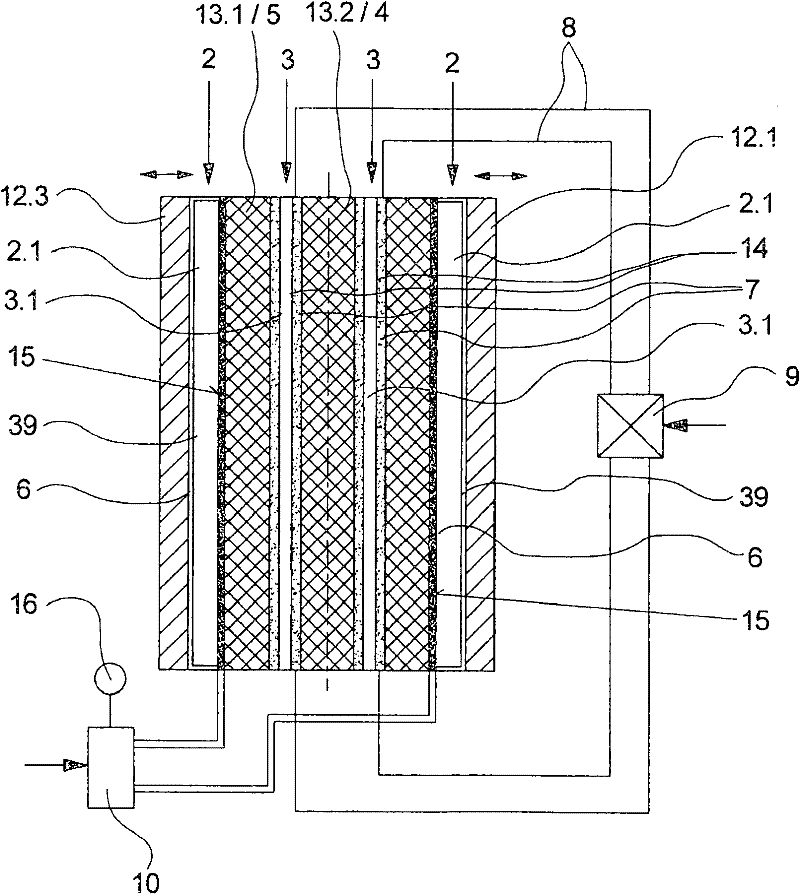

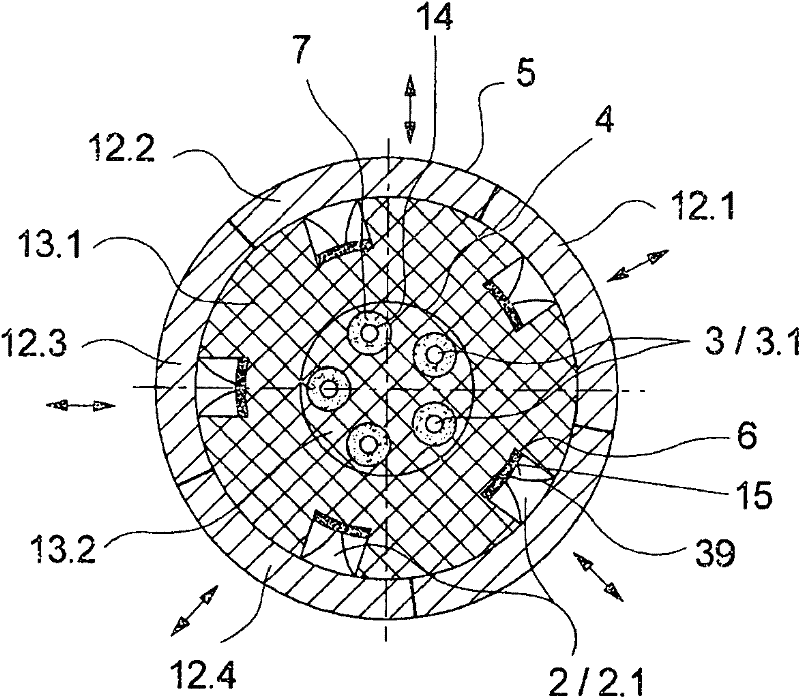

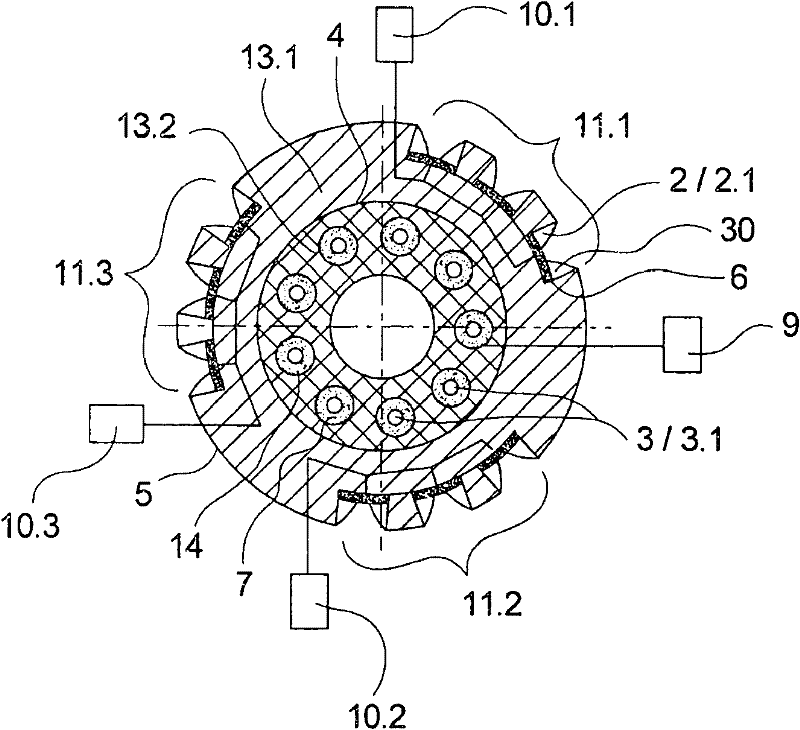

[0033] figure 1 shows a schematic longitudinal sectional view of a first embodiment of a heating device according to the invention, while figure 2 A cross-sectional view is shown. If there is no explicit reference to one of the figures, the following description applies to both figures.

[0034] The heating device has a plurality of heated heating channels 2.1 and 3.1. The heating channels 2.1 and 3.1 are divided into two heating groups 2 and 3 . The heating channels 2.1 of the heating group 2 are formed in the edge region 5 of the heating device. The individual heating channels 3 . 1 of the heating group 3 are arranged in the central region 4 , they are located concentrically in the center of the edge region 5 and are surrounded by the edge region 5 . The heating channels 2.1 of the heating group 2 are arranged concentrically with the heating channels 3.1 of the heating group 3 and surround them. In this exemplary embodiment, the heating group 2 consists of a total of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com