Method for preparing large-grain magnesium hydroxide by taking highly acid ammonium salt as crystal control agent

A technology of magnesium hydroxide and crystal control agent, applied in magnesium hydroxide and other directions, can solve the problems of high water content in the filter cake, difficult to filter and wash, and high concentration of free ammonia, achieve high purity, increase utilization rate, and low investment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

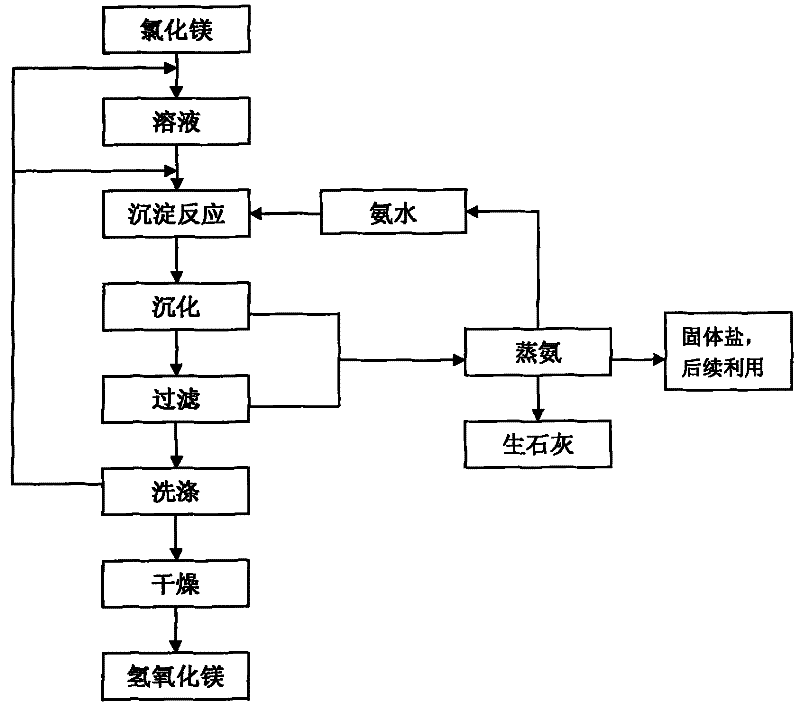

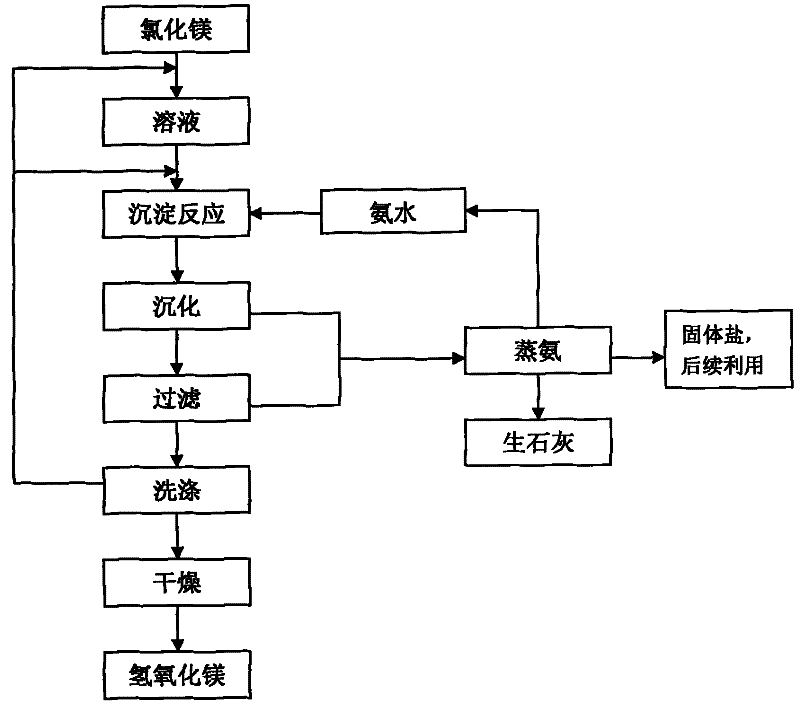

Method used

Image

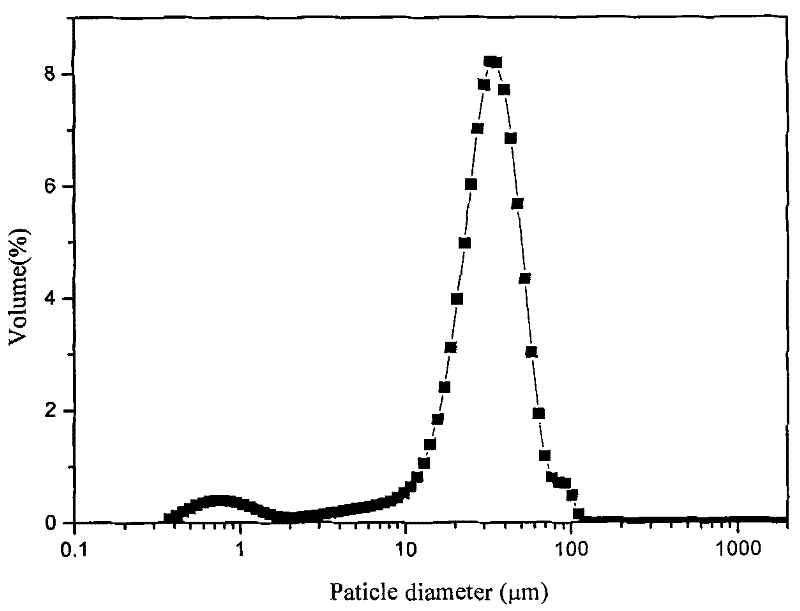

Examples

Embodiment 1

[0042] Continuous

[0043] (1) configuration concentration is the magnesium chloride solution of 4mol / L;

[0044] (2) Add 0.2mol ammonium chloride as a crystal control agent in the reactor, heat to 80°C and maintain a constant temperature;

[0045] (3) Mix the prepared magnesium chloride solution and ammonia according to the MgCl 2 : NH 3 = The ratio of 1: 2 is added to the reaction kettle at the same time, and it is constantly stirred;

[0046] (4) Product discharge After reacting to a certain degree, the magnesium hydroxide crystal slurry is discharged continuously through the overflow outlet that the liquid surface goes out;

[0047] (5) After the obtained magma is precipitated, the clear night of the upper layer is discharged; the lower layer of sediment is filtered, washed and dried to obtain solid magnesium hydroxide.

Embodiment 2

[0049] Intermittent

[0050] (1) configuration concentration is the magnesium chloride solution of 2mol / L;

[0051] (2) Add 1 mol of ammonium chloride in the reactor as a crystal control agent, heat to 90°C and maintain a constant temperature;

[0052] (3) Add ammonia water to the reaction kettle at a rate of 4mL / min, and control the MgCl 2 : NH 3 =1:1.8, after the reaction is completed, inject the reaction solution into the settling tank, and settle for 30 minutes;

[0053] (4) After the obtained magma is precipitated, the clear night of the upper layer is discharged; the lower layer of precipitate is filtered, washed and dried to obtain magnesium hydroxide solid.

Embodiment 3

[0054] Embodiment 3: difference with embodiment 1 is: strong acidic ammonium salt is ammonium sulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com