Human-machine interconnect type intelligently-controlled mass drill equipment

An intelligent control and group drilling technology, which is applied in the direction of automatic control devices, feeding devices, manufacturing tools, etc., can solve the problems of fewer processes and simple processing equipment, and achieve the effects of simple processes, improved processing accuracy, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

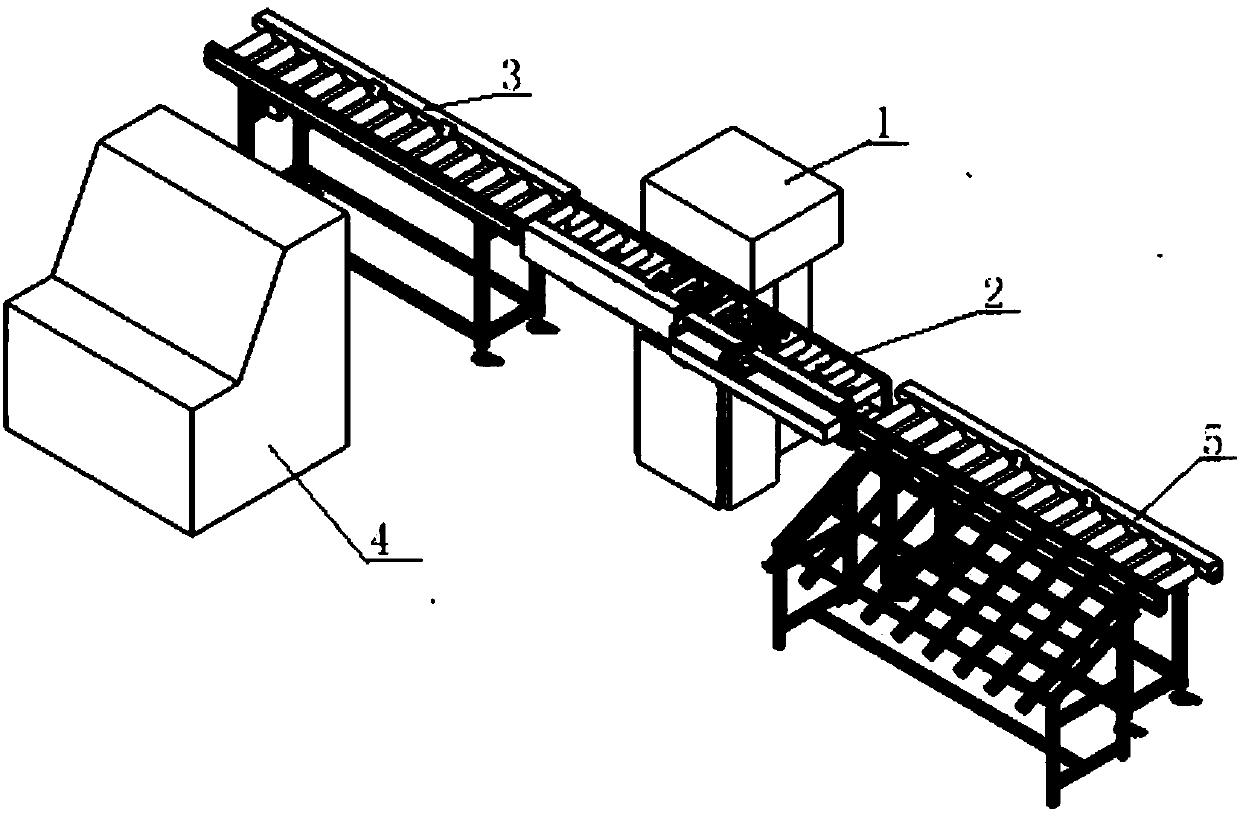

[0023] A human-computer interconnection intelligent control group drilling equipment, the structure is as follows figure 1 , 2 As shown, it includes an upper computer PC and a longitudinally extending feeding track. The feeding track includes a feeding section 3, a processing section 2 and a feeding section 5. One side of the feeding section 3 is provided with a two-dimensional code scanning device, and the processing section 2. A material positioning and clamping mechanism and a group drilling mechanism 1 are provided. The material positioning and clamping mechanism and the group drilling mechanism 1 are connected to a PLC controller. Both the two-dimensional code scanning device and the PLC controller are connected to the PC signal of the upper computer.

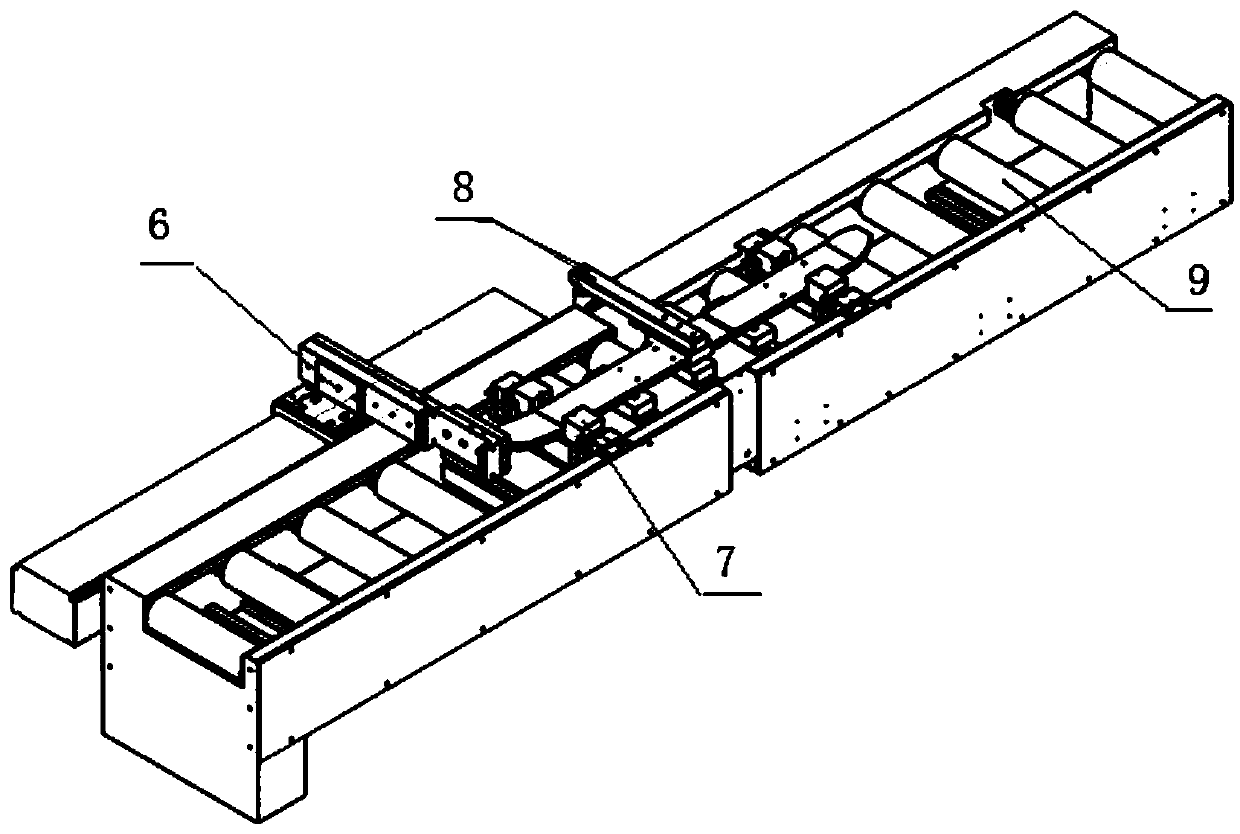

[0024] The material positioning and clamping mechanism includes a centering clamping device and an upper pressing device. The centering clamping device includes a number of clamping cylinders 7 arranged on the left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com