Manufacturing method for plastic molding machine cylinder

A manufacturing method and molding machine technology, applied in the field of extruder barrel manufacturing and plastic molding machine barrel manufacturing, can solve problems such as barrel corrosion or wear, screw and barrel corrosion and wear, and achieve excellent wear resistance The effect of loss and excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

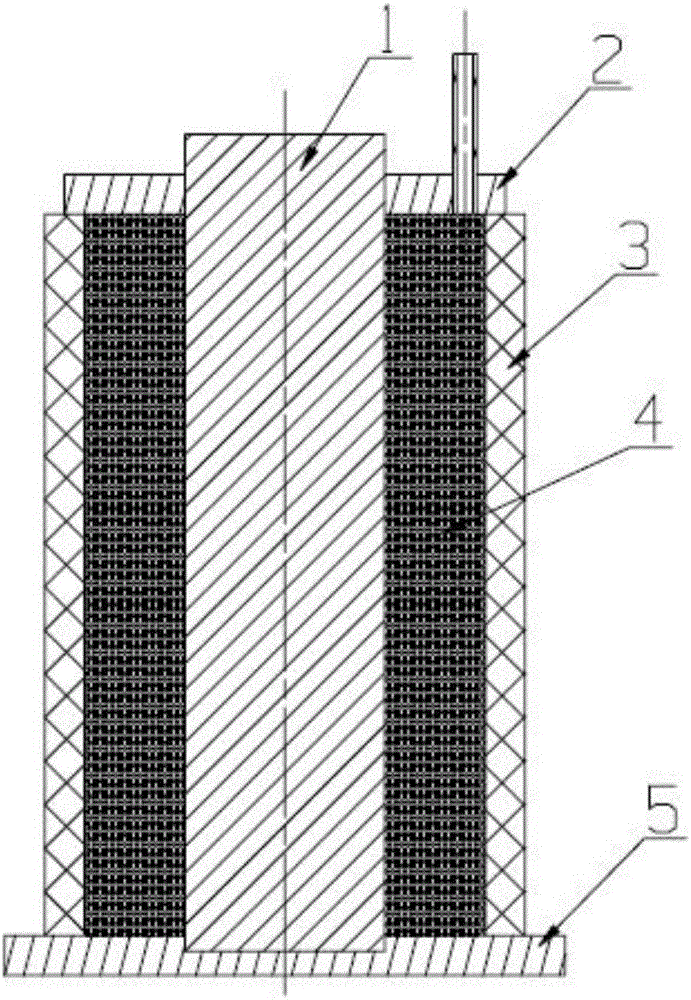

[0024] according to figure 1 The structure shown makes the barrel. The material of the steel barrel is 42CrMoA, and its alloy composition is 0.37-0.44% of C, 0.17-0.37% of Si, 0.50-0.80% of Mn, 0.80-1.10% of Cr and the balance of Fe according to the mass percentage. . The hot isostatic pressing sintered alloy powder is a cobalt-based tungsten carbide alloy, wherein the mass content of WC is 68%; according to the mass percentage content, the cobalt-based tungsten carbide alloy binder phase composition is 29.50% Cr, 7.40% Mo and other amount of Co; the hot isostatic pressing sintering is carried out under the vacuum of the air in the sleeve, the hot isostatic pressing sintering temperature is 1050-1150 °C, the ambient gas is argon, and its pressure is 160Mpa.

Embodiment 2

[0026] according to figure 1 The structure shown makes the barrel. The steel barrel material is 40Cr, and its alloy composition is 0.38-0.45% C, 0.17-0.37% Si, 0.50-0.80% Mn, 0.90-1.20% Cr, 0.15-0.25% Mo and the balance of Fe. The tungsten carbide alloy powder material is NiMoCrFeCo-WC alloy powder, wherein the mass content of WC is 72%; according to the mass percentage content, the composition of NiMoCrFeCo is 28.0% Cr, 1.2% Fe, 15% Mo, 4.5% Co , 0.02% of C, 0.03% of Mn, 0.06% of Si, 0.03% of Al, 2.0% of W, 0.5% of V and the rest of Ni, the hot isostatic pressing sintering is carried out under the air in the jacket , Hot isostatic pressing sintering temperature 1150 ~ 1250 ℃, the ambient gas is argon, and its pressure is 145Mpa.

Embodiment 3

[0028] according to figure 1 The structure shown makes the barrel. The material of the steel barrel is 42CrMoA, and its alloy composition is 0.37-0.44% of C, 0.17-0.37% of Si, 0.50-0.80% of Mn, 0.80-1.10% of Cr and the balance of Fe according to the mass percentage. . The hot isostatic pressing sintered alloy powder is a cobalt-based tungsten carbide alloy, wherein the mass content of WC is 50%; according to the mass percentage content, the cobalt-based tungsten carbide alloy binder phase composition is 34.50% Cr and the balance Co; The isostatic sintering is carried out under the condition that the air in the sleeve is removed, the hot isostatic sintering temperature is 1050-1150°C, the ambient gas is argon, and the pressure is 160Mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com