Mould closing device for plastic forming machine

A mold clamping device and molding machine technology, which is applied in the field of plastic molding machines, can solve the problems of slowing down mold clamping speed, mold expansion, easy breakage, etc., and achieve the effects of speeding up mold clamping speed, improving production efficiency, and ensuring quality

Inactive Publication Date: 2013-10-09

WEIFANG HUAYU PLASTIC MACHINERY

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The traditional mold clamping machine has the following disadvantages: 1. In order to ensure sufficient mold clamping force, it must be equipped with a mold clamping cylinder with a relatively large diameter, and the large mold clamping cylinder brings large mold clamping force while the oil pump flow rate is constant. In some cases, the mold clamping speed will be seriously slowed down, and the low mold clamping speed restricts the production efficiency of the plastic molding machine; 2. When producing large-scale plastic hollow molding products, a mold clamping cylinder may have insufficient clamping force The phenomenon, which leads to the phenomenon of mold expansion, the product produced in this way has a poor molding effect at the clamping line and is easy to break

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach

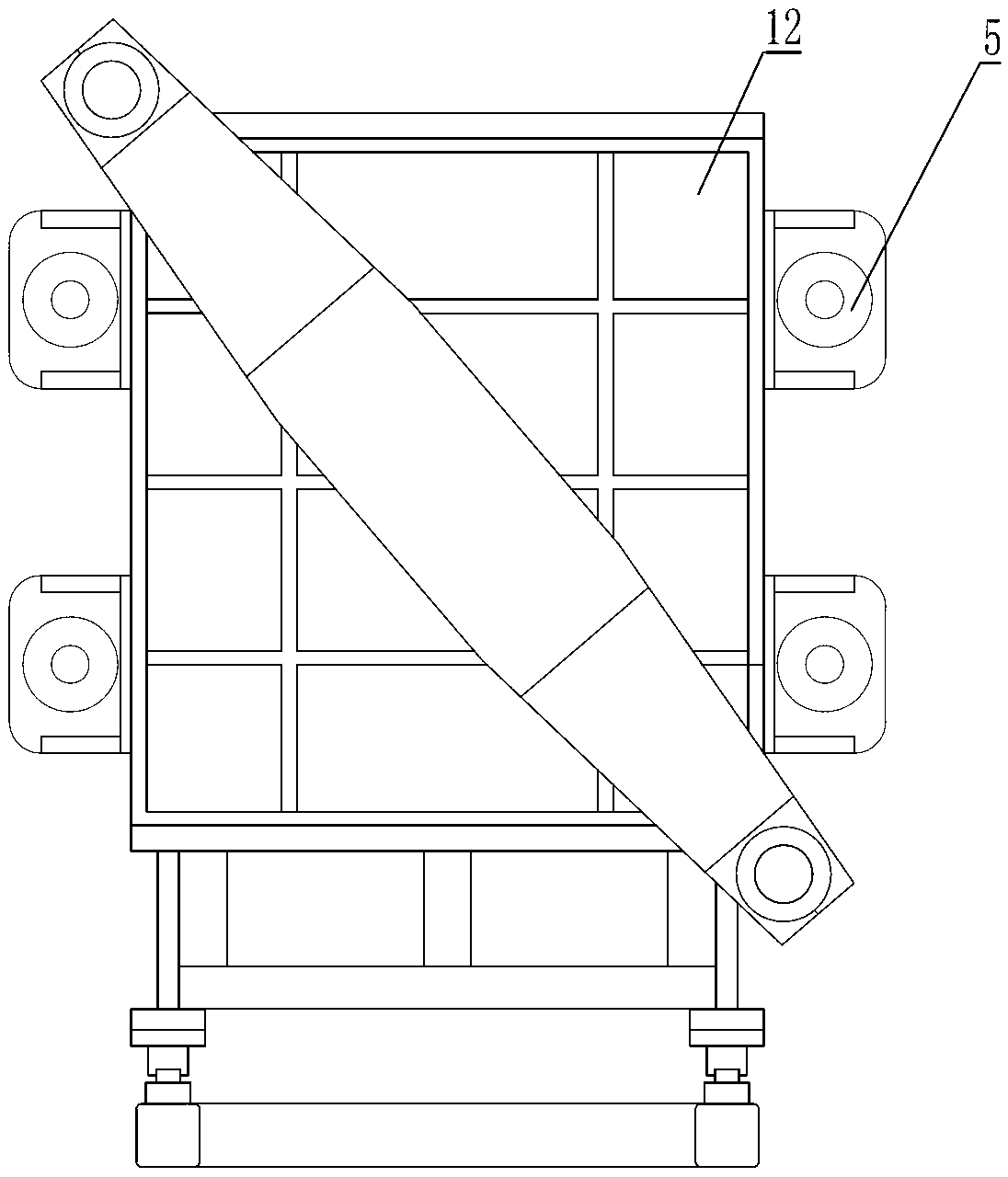

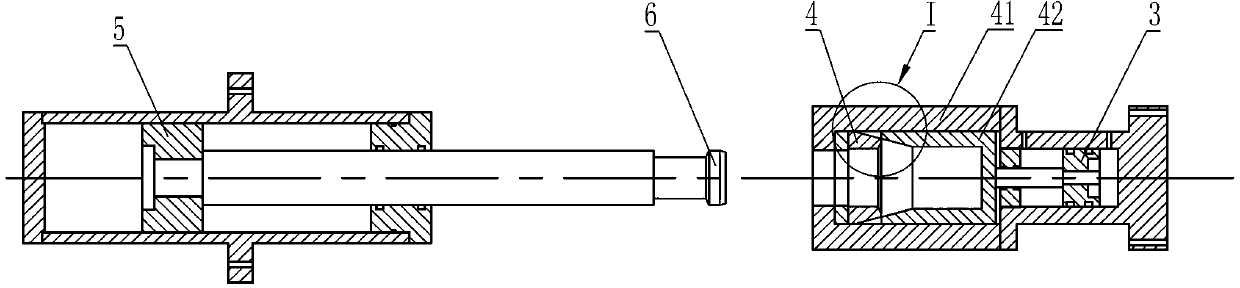

[0029] As another specific implementation manner, the ferrule driving cylinder 3 is installed on the second template 12 , and the chuck driving cylinder 5 is correspondingly installed on the first template 11 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

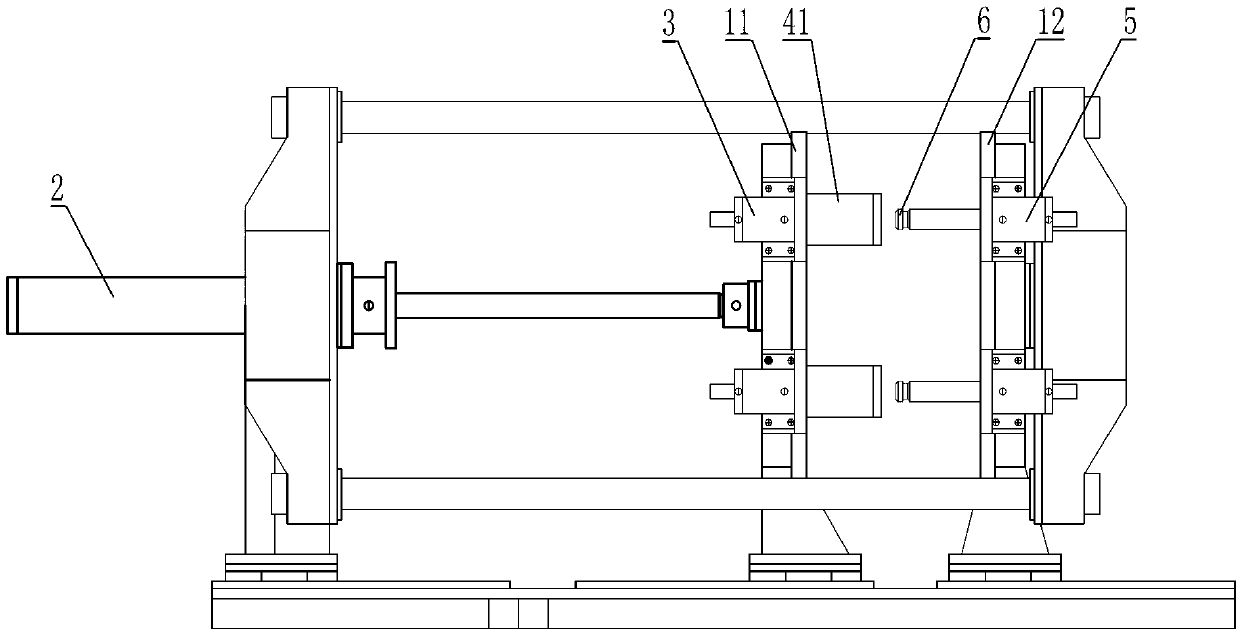

The invention discloses a mould closing device for a plastic forming machine. The mould closing device comprises a first mould plate and a second mould plate which are arranged on a rack, wherein the first mould plate is connected with a mould closing oil cylinder, at least one pair of clamping sleeve drive oil cylinders are arranged at two sides of the first mould plate, each clamping sleeve drive oil cylinder is connected with a clamping sleeve connecting device, clamping head drive oil cylinders in one-to-one correspondence with the clamping sleeve drive oil cylinders are arranged on the second mould plate, and clamping head connecting devices matched with the clamping sleeve connecting devices are arranged on the clamping head drive oil cylinders. In a mould closing process, under the action of the clamping sleeve drive oil cylinders and the clamping head drive oil cylinders, the clamping sleeve connecting devices and the clamping head connecting devices are matched and connected to provide a uniform and stable mould locking pressure for mould closing, and the mould closing oil cylinder can provide no mould closing force or a little mould locking force, so that product quality can be ensured while the load of the mould closing oil cylinder is reduced. The mould closing oil cylinder with small diameter can be adopted, and thus the mould closing speed and the production efficiency are improved.

Description

technical field [0001] The invention relates to a plastic molding machine, in particular to a mold clamping device matched with the plastic molding machine. Background technique [0002] The traditional mold clamping machine has the following disadvantages: 1. In order to ensure sufficient mold clamping force, it must be equipped with a mold clamping cylinder with a relatively large diameter, and the large mold clamping cylinder brings large mold clamping force while the oil pump flow rate is constant. In some cases, the mold clamping speed will be seriously slowed down, and the low mold clamping speed restricts the production efficiency of the plastic molding machine; 2. When producing large-scale plastic hollow molding products, a mold clamping cylinder may have insufficient clamping force The phenomenon, which leads to the phenomenon of mold expansion, the product produced in this way has a poor molding effect at the parting line and is easy to break. Contents of the in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C33/24

Inventor 王玉宽李海元翟光彩周炳宇王卫强

Owner WEIFANG HUAYU PLASTIC MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com