Central vacuum system of foam-plastic forming machine

A vacuum system and molding machine technology, applied in the mechanical field, can solve problems such as the drop of drainage switching pressure and affect product quality, and achieve the effect of ensuring the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

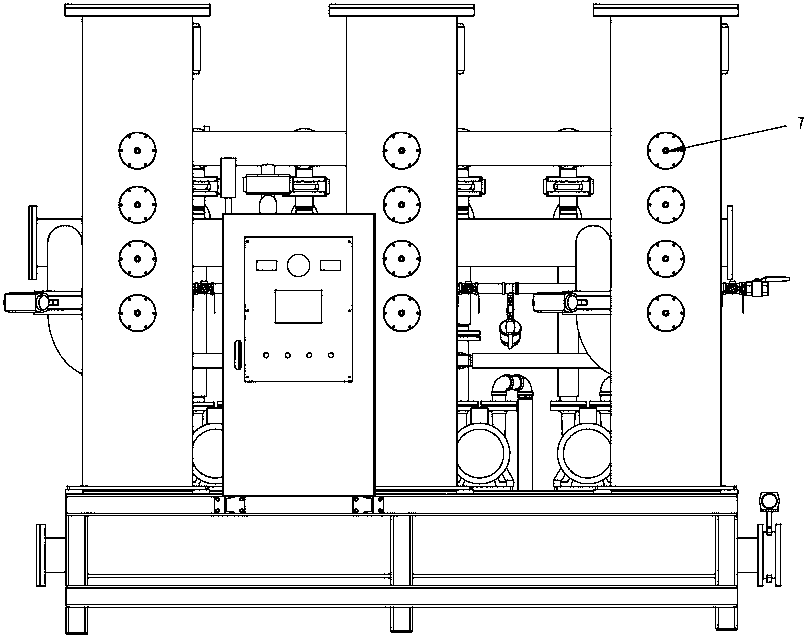

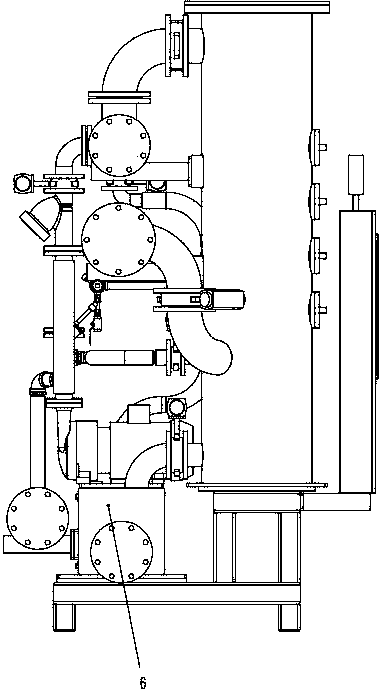

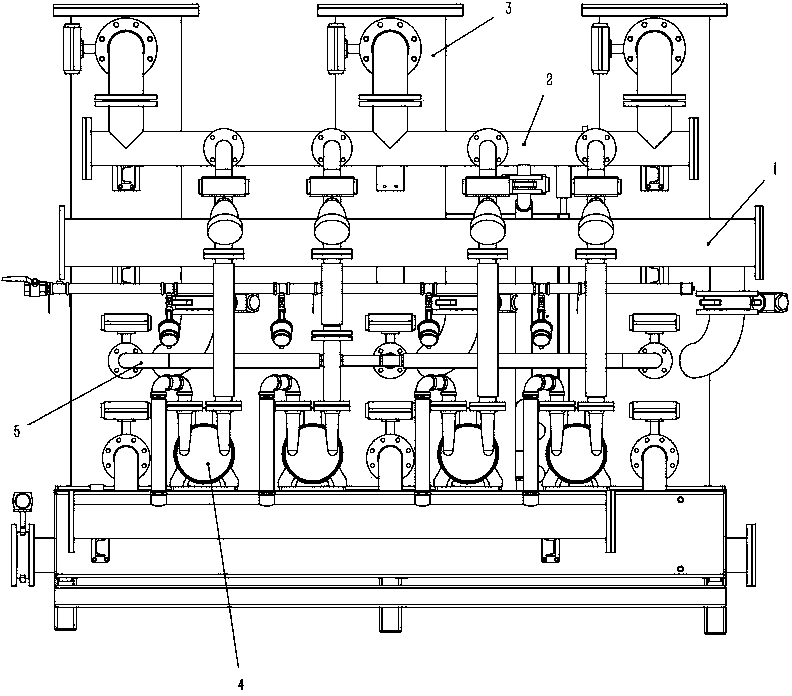

[0013] Such as Figure 1-4 As shown, the central vacuum system includes an intake pipe 1, a distribution pipe 2, a condensation bucket 3, a vacuum pump 4, an auxiliary vacuum pipeline 5, a drainage tank 6 and a sprayer 7, and three condensation buckets 3, one Drainage box 6 and several vacuum pumps 4, air intake pipeline 1 communicates with condensing bucket 3 respectively, the upper part of condensing bucket 3 is connected with distribution pipeline 2 through the upper valve, the bottom of condensing bucket 3 is connected with drainage box 6 through the lower valve, and the middle part of condensing bucket 3 is through The auxiliary vacuum valve is connected with the auxiliary vacuum pipe 5, the vacuum pump 4 is connected with the distribution pipe 2 and the drainage tank 6, and the condensation barrel 3 is equipped with a number of showers 7, which constitute the central vacuum system as a whole.

[0014] When the central vacuum system is working, the gas in the main pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com