Waste mixed plastic recovery and separation device and method

A technology of mixed plastics and separation devices, which is applied in the field of recycling and separation devices for waste mixed plastics, which can solve the problems of low purity of manual sorting, low efficiency of sorting and extraction, etc., to reduce production costs and energy consumption, and to achieve a high degree of sorting , The effect of high recovery and separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

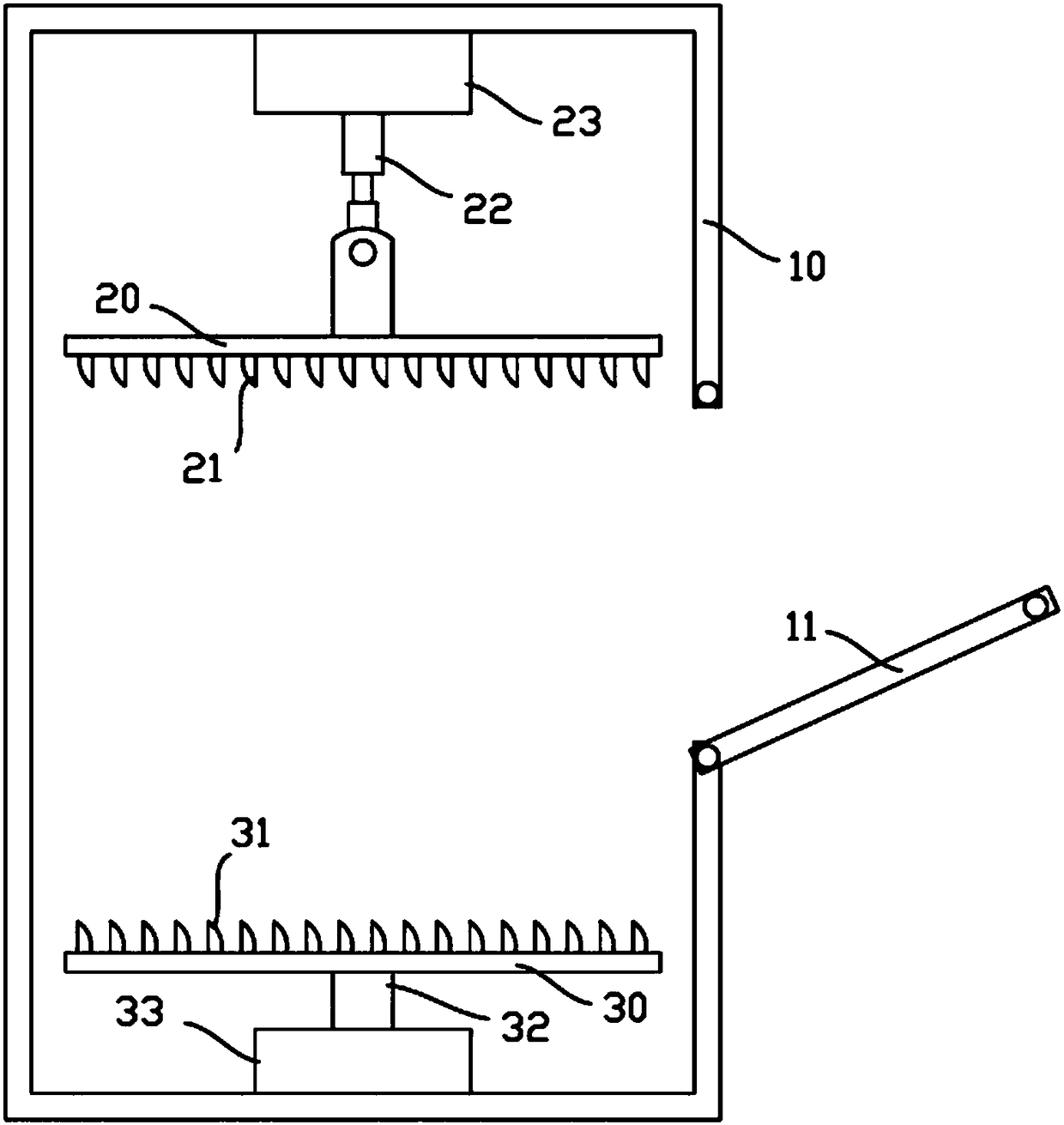

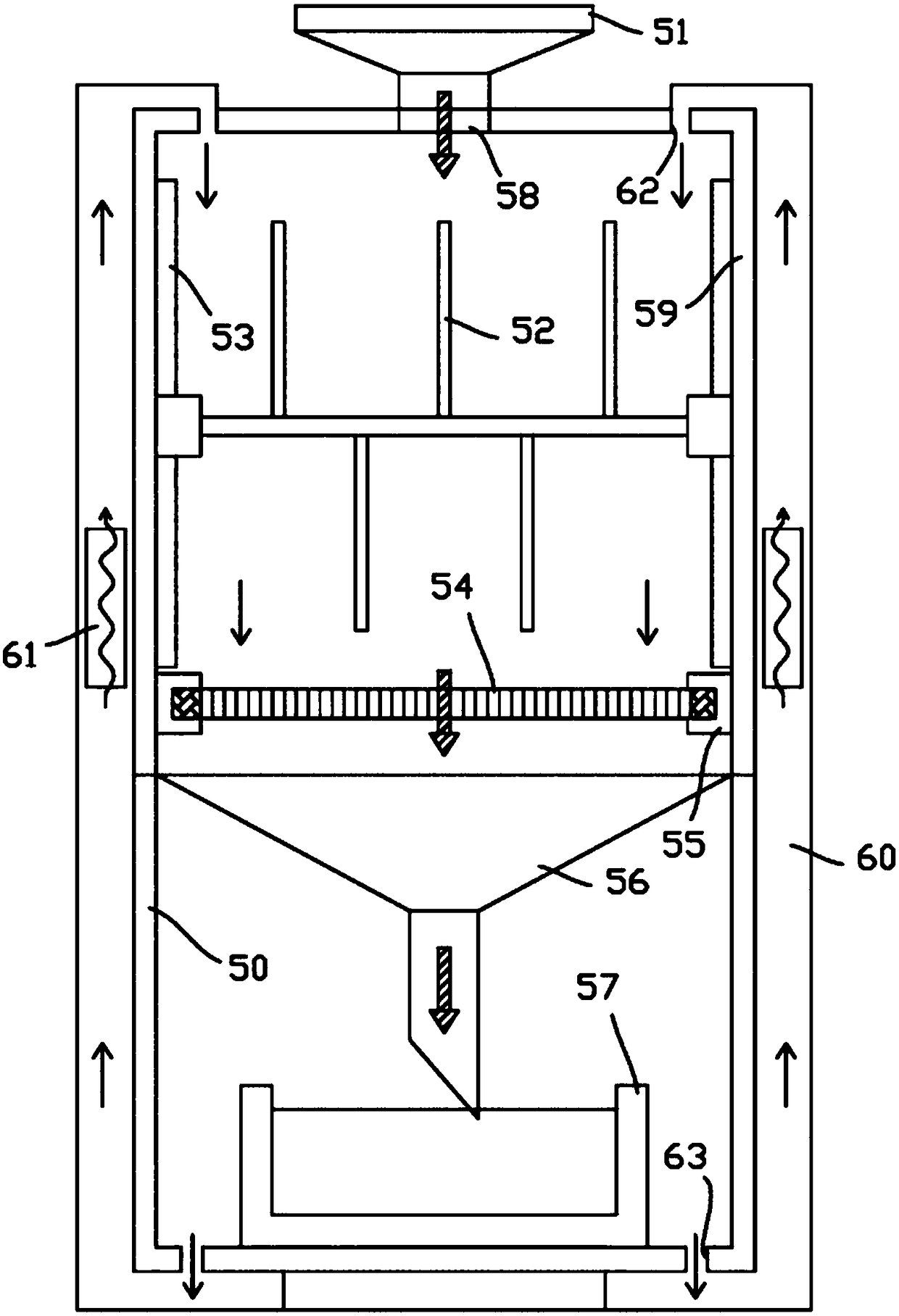

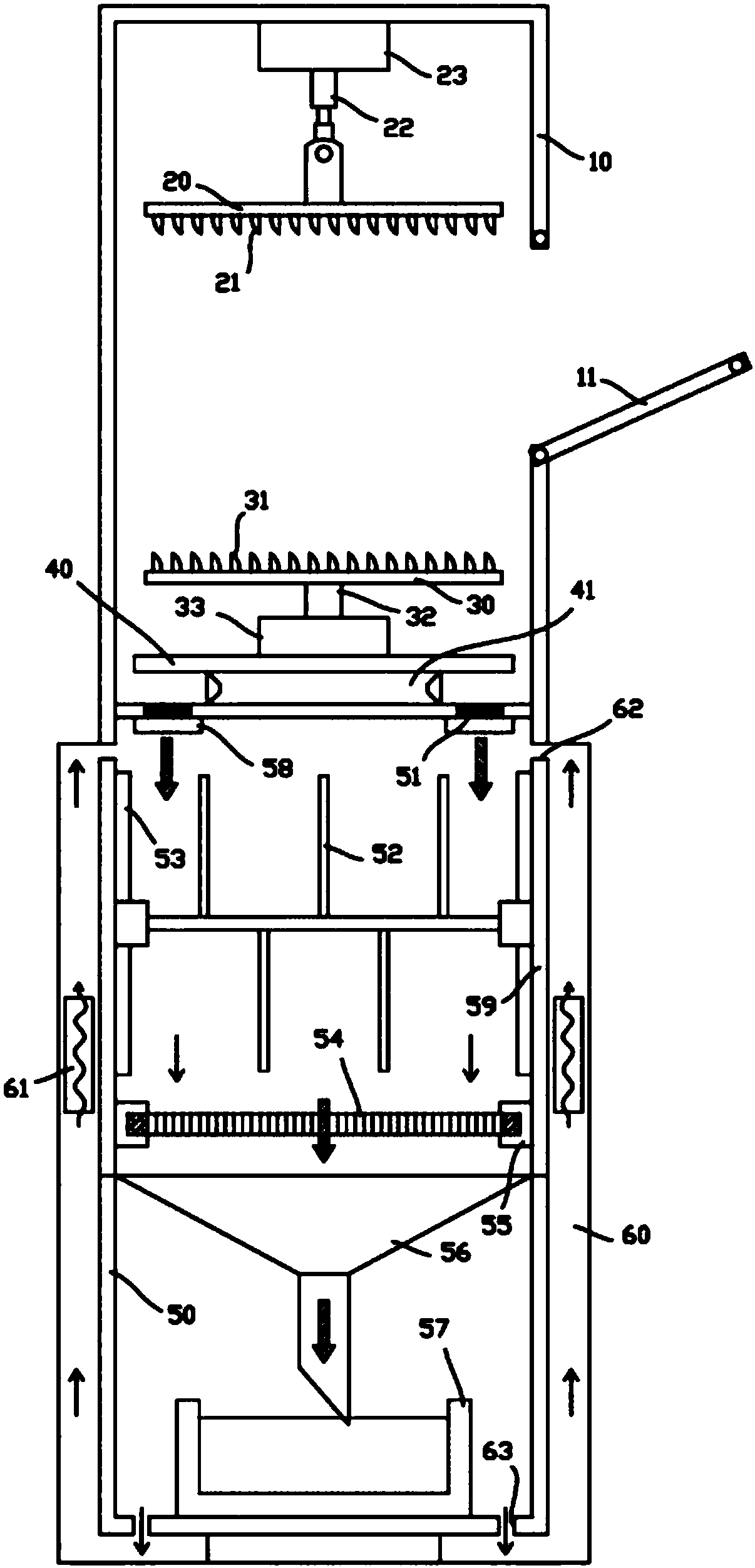

[0030] The device for recycling and separating waste mixed plastics of the present invention includes a crushing device and a melting, sorting and recycling device. As a first embodiment of the present invention, please refer to figure 1 , the crushing device includes a crushing box 10, and the crushing box 10 is provided with a feeding mechanism that allows waste and old mixed plastics to enter the crushing box 10, a crushing mechanism that crushes waste and old mixed plastics into granular materials, and crushes the crushed granular materials. The material is discharged to the discharge mechanism of the melting separation recovery device. The feeding mechanism includes a rotary box door 11 placed on the side wall of the crushing box 10 to facilitate the entry of waste and old mixed plastics into the crushing box 10 .

[0031] The crushing mechanism includes a rotating platform 30 placed at the bottom of the crushing box 10 and controlled to rotate by a rotating mechanism, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com