Novel spinning machine

A spinning machine, a new type of technology, applied in the field of plastic forming machinery, can solve the problems of unstable operation, uneven deformation, poor mechanical properties, etc., to achieve the effect of guaranteed operation stability, short operation time, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

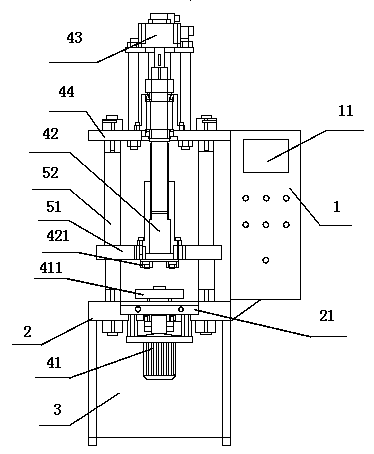

[0009] As an embodiment of the present invention, such as figure 1 As shown, a new type of spinning machine includes a control box 1, a workbench 2, a circuit box 3 and a spinning mechanism. Reinforcing ribs are provided, and preferably, the line box 3 is provided below the workbench 2 .

[0010] The spinning mechanism includes a motor 41 mounted on the workbench 2, a lower clamp 411 mounted on the motor 41, a spinning head 42 arranged opposite to the motor 41, and an upper clamp 421 mounted on the spinning head 42. , and a servo motor 43 for driving the spinning head 42 . The motor 41 is installed upside down on the worktable 2, and the lower clamp 411 for fixing the workpiece is installed on the output end of the motor 41, and the motor 41 provides power for the rotation of the workpiece. The upper fixture 421 is arranged at the lower part of the spinning head 42, and corresponds to the position of the lower fixture 411,

[0011] In order to ensure the stable operation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com