Plastic molding machine with automatic sorting and molding functions

An automatic sorting and forming machine technology, applied in sorting, plastic recycling, recycling technology, etc., can solve problems such as material overflow, and achieve the effects of saving time, reducing costs, and reducing manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

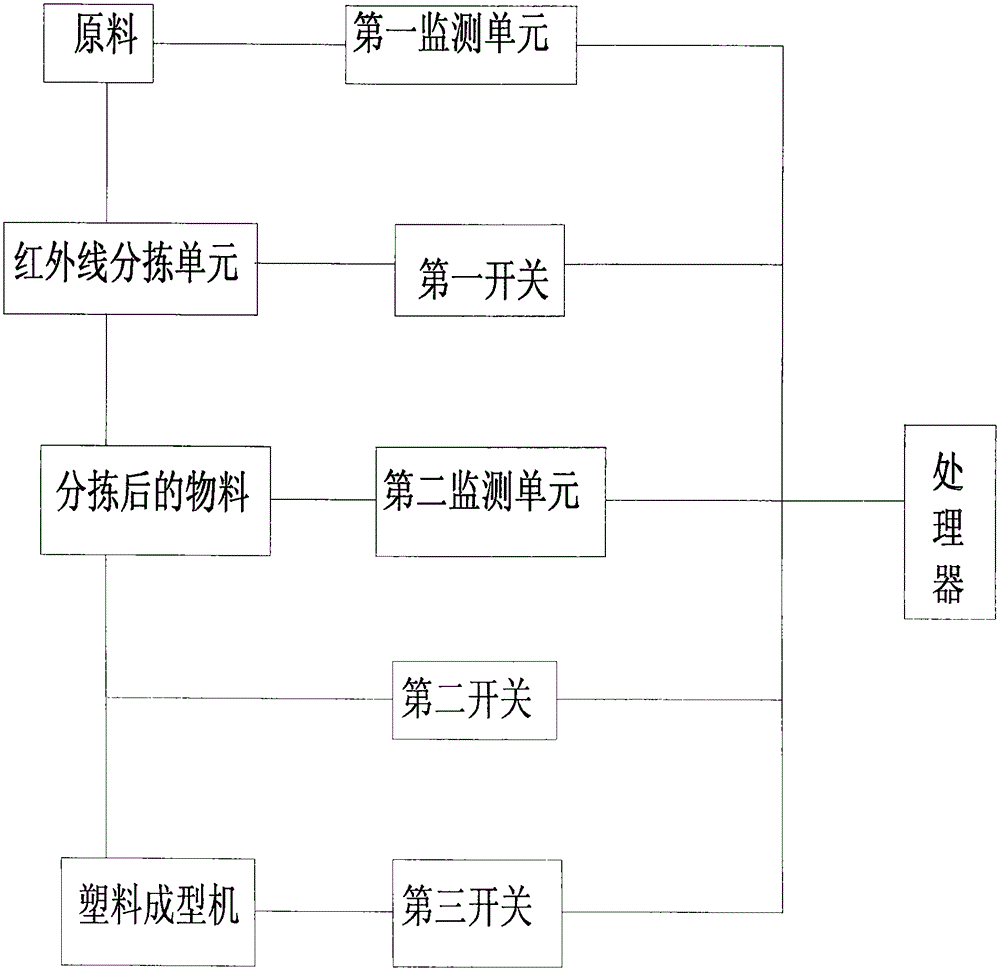

[0016] Such as figure 1 As shown, the plastic molding machine with automatic sorting and molding functions of the present invention includes an infrared sorting unit, a control unit and a plastic molding machine.

[0017] The infrared sorting unit includes a feeding mechanism, a sorting mechanism arranged at the lower end of the feeding mechanism, and a collecting mechanism that can collect materials sorted by the sorting mechanism and is located above the extruder.

[0018] Specifically, the feeding mechanism can be a hopper for raw materials containing PVC, PP, PET and / or other recyclable plastics to enter, and the collecting mechanism is two boxes for containing materials, one of which has a bottom of the box Opening, a bottom plate, a shrapnel and a solenoid valve, the solenoid valve can cooperate with the shrapnel so that the bottom plate can be opened to close the opening; the other box is used to hold other than the materials to be sorted out Other mixtures, so the gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com