Plastic extrusion injection molding machine with injection connecting rod defective material cleaning function

A molding machine and residual material technology, which is applied in the field of plastic extrusion injection molding machines, can solve the problems of not being too large in one-time injection, affecting the quality of plasticization, and not easy to remove, so as to achieve excellent cleaning effect, save cleaning time, and save cleaning cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

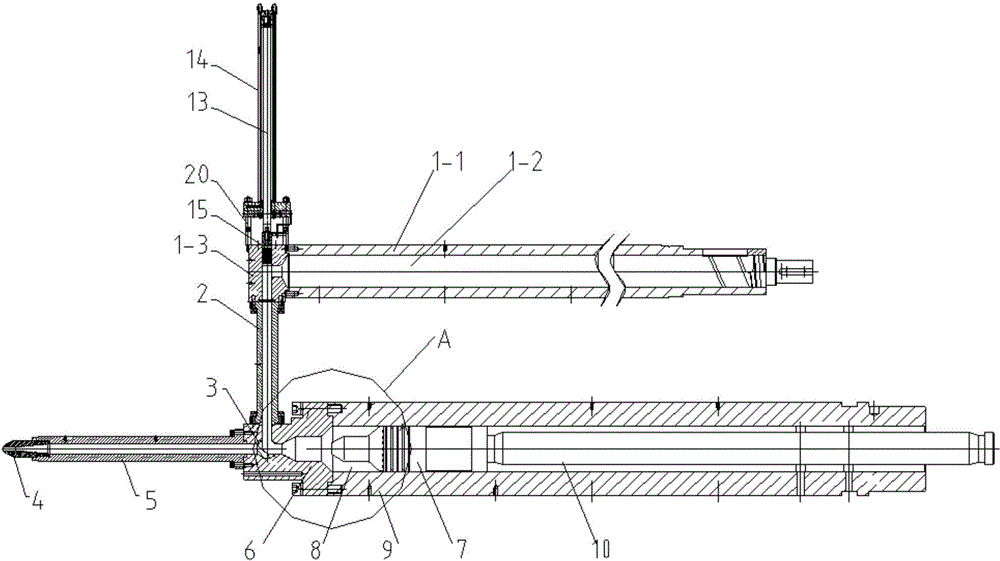

[0038] Such as figure 1 , Figure 9 with Figure 10 A plastic extrusion molding machine with material cleaning function is shown, including an injection component and a plasticizing component, the injection component and the plasticizing component are connected through an injection connecting rod 2, and the plasticizing component includes a plasticizing screw 1-2, a pre-plasticizing The front feed barrel 1-3 and the plasticizing feed barrel 1-1, the pre-plastic front feed barrel is provided with a feed passage 16 communicating with the injection rod 2 (see Figure 10 ), the feeding channel is L-shaped, the central axis of the vertical section of the feeding channel and the central axis of the injection rod are on a straight line, and the horizontal section of the feeding channel 16 communicates with the inner cavity of the plasticizing barrel 1-1 , and the end of the horizontal section of the feeding channel 16 connected to the plasticizing barrel 1-1 is a bell mouth. The i...

Embodiment 2

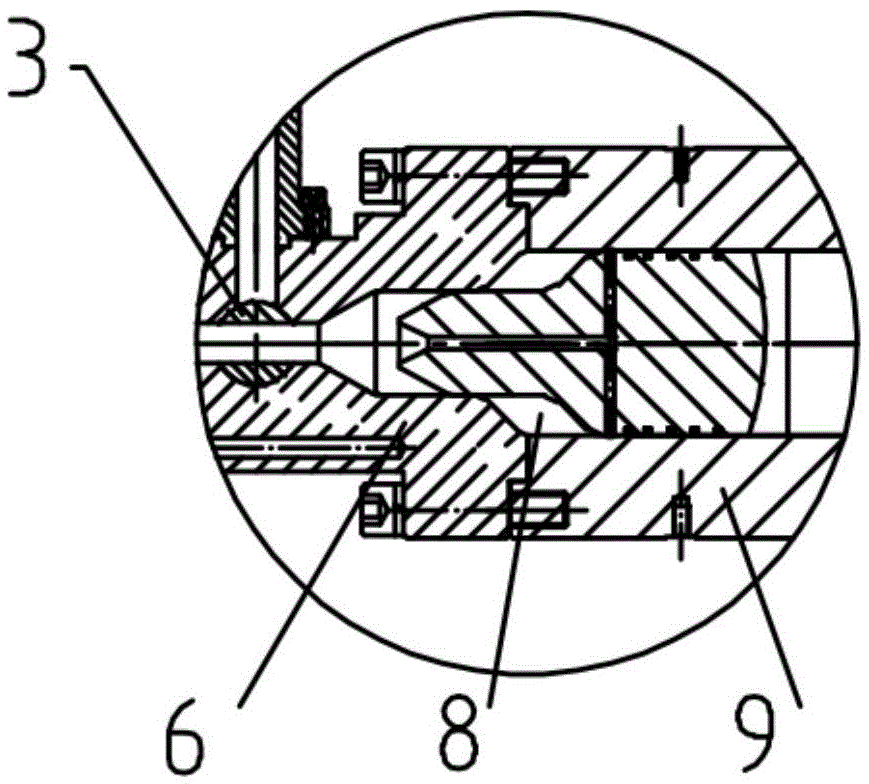

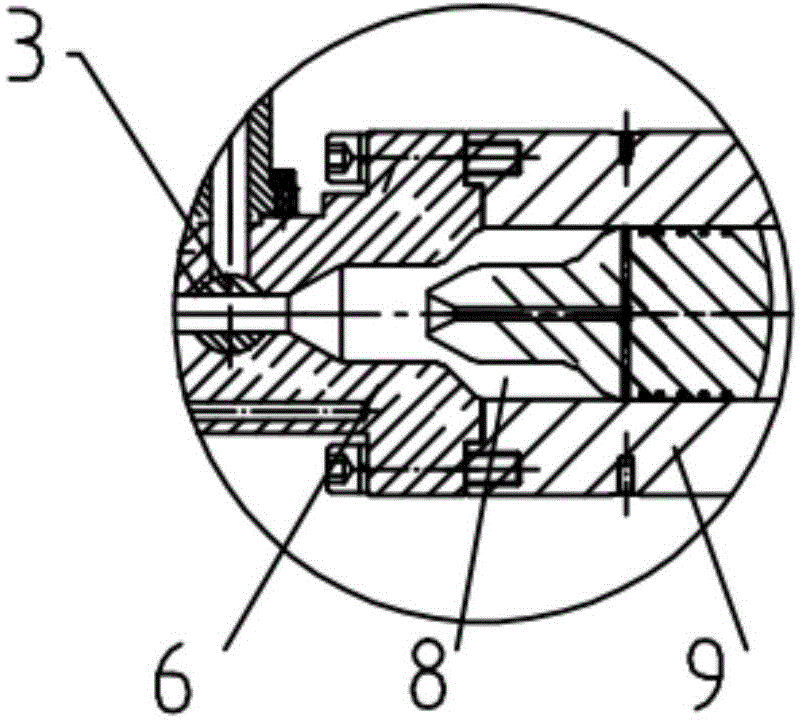

[0045] A kind of plastic injection molding machine, it except having all structures described in embodiment 1, also has a figure 2 , image 3 , Figure 5 , Image 6 with Figure 7 As shown, the main body 7-1 of the injection plunger is a cylinder, which has a conical injection head 7-3, and a cleaning step 7-2 is set between the injection head and the main body, and the cleaning step is formed by the second cylinder 7 -4 is connected with the second circular platform 7-5, the other end of the second cylinder is connected with the bottom of the circular platform of the injection head, and the other end of the second circular platform is connected with the main body. The pre-injection barrel has a cavity wall that matches the injection head of the injection plunger and the outer contour of the purge step (see Figure 4 ).

[0046] The injection head, the cleaning step and the main body are rotating bodies with the same axis. The main body of the injection plunger is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com