Thermoplastic elastomer used for electric car charging pile cable and preparing method of thermoplastic elastomer

A thermoplastic elastomer, electric vehicle technology, applied in the field of thermoplastic polymer materials, can solve the problem of poor comprehensive performance of tear resistance, heat resistance, oil resistance, heat resistance and scratch resistance, tear resistance and heat resistance To solve the problems of poor performance, to achieve excellent flame retardancy, improved tear resistance and oil resistance, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

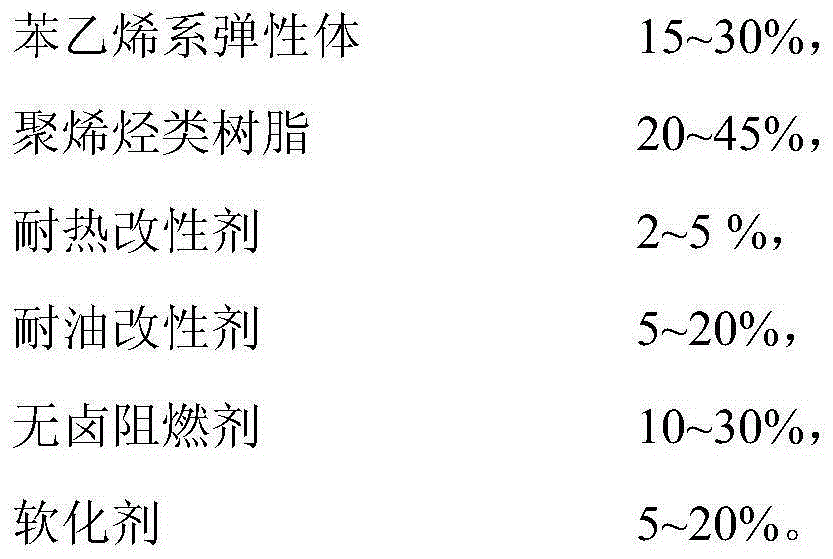

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment the present invention is described in further detail.

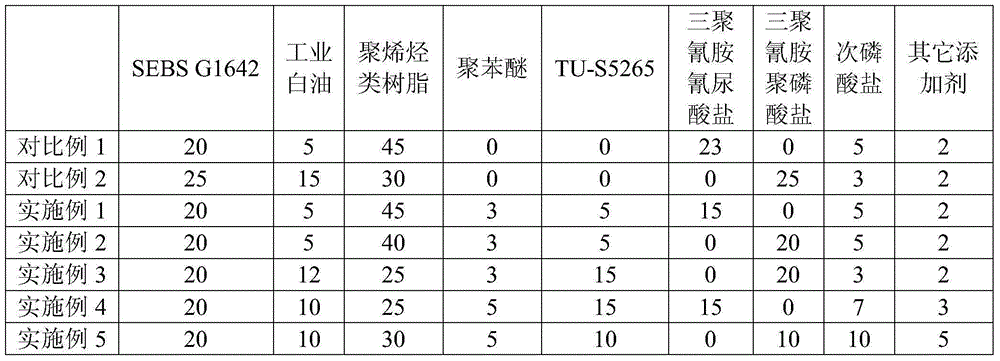

[0029] As a comparison, two comparative examples were selected for comparison with the examples. Both comparative example 1 and comparative example 2 were flame-retardant TPE materials belonging to the nitrogen-phosphorus flame-retardant system, and the flame-retardant TPE material of comparative example 1 was not added with oil-resistant modification agent, the hardness is 85A, the flame retardant TPE material of Comparative Example 2 does not add oil resistance modifier, and the hardness is 70A. The comparative examples and the examples are first made into pellets by the preparation method of the present invention, and then performance testing is carried out respectively. See Table 1 below for the proportions by weight of the Examples and Comparative Examples, and Table 2 below for their properties and comparative results.

[0030] Referring to UL1581 "Reference Standards for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com