Full automatic foam plastic forming machine of two opposite-clamping type templates

A technology of foam plastics and molding machines, which is applied in the field of formwork structures, can solve problems such as power consumption and slow running speed, and achieve the effects of faster running speed, reduced frictional resistance, and shorter running distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

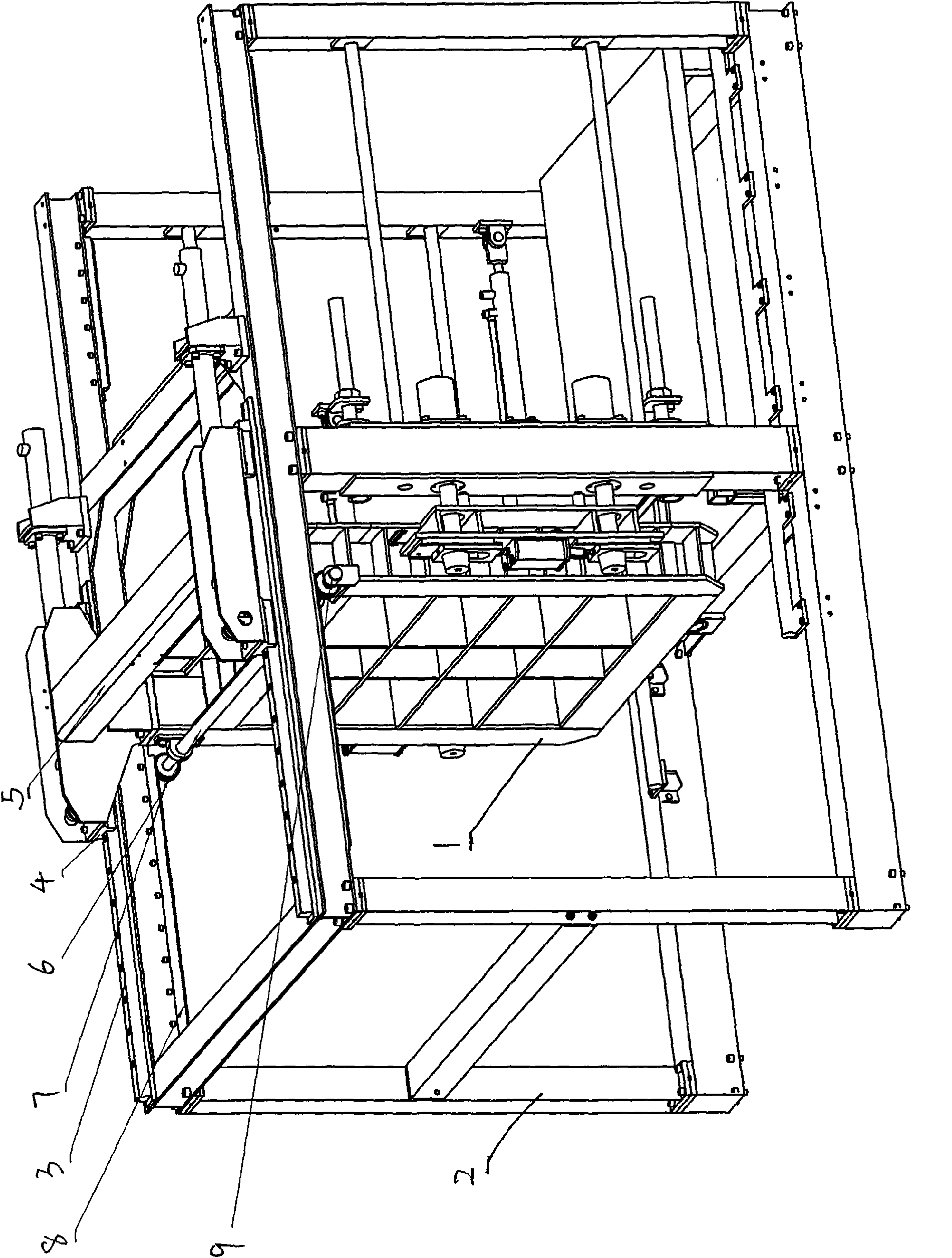

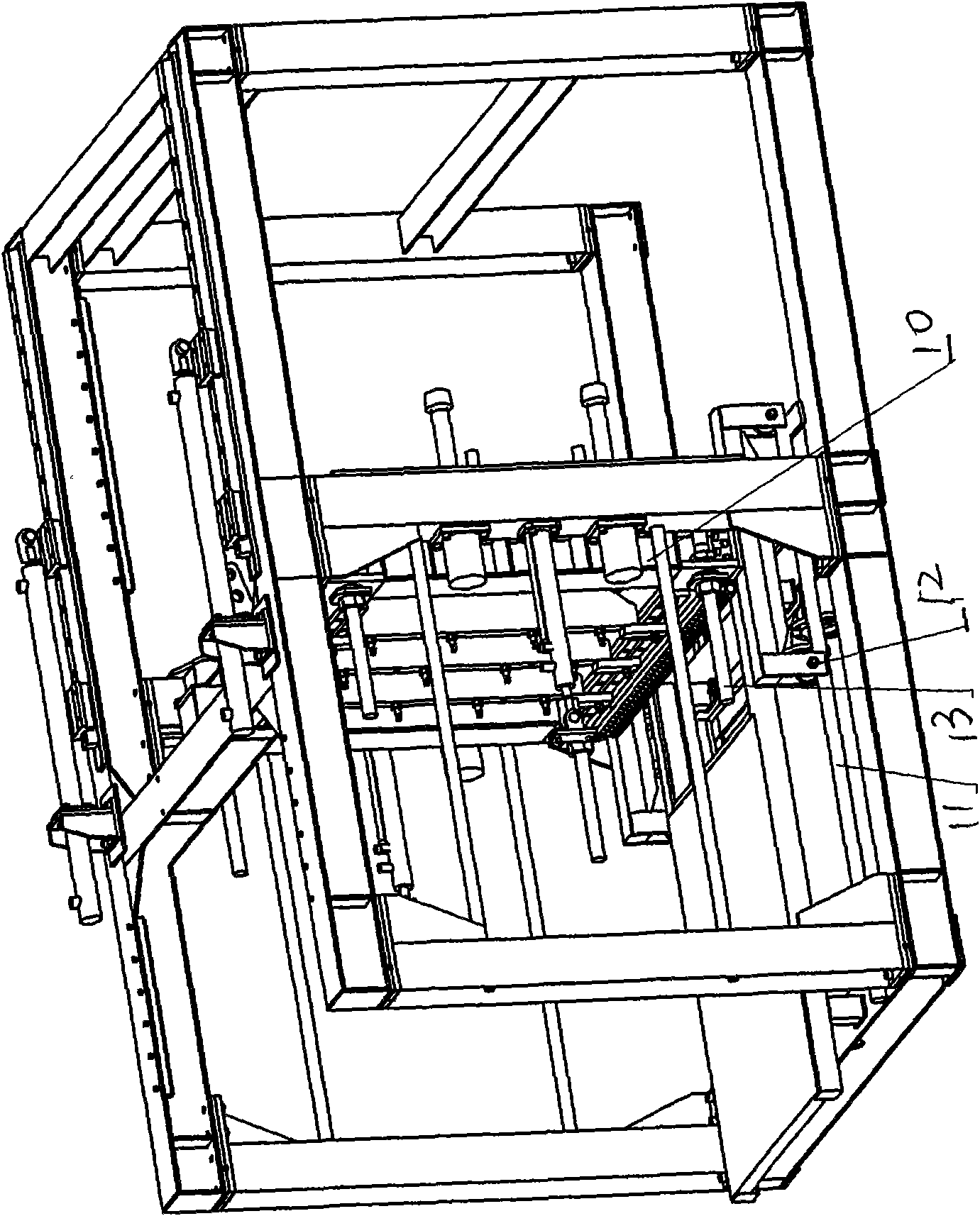

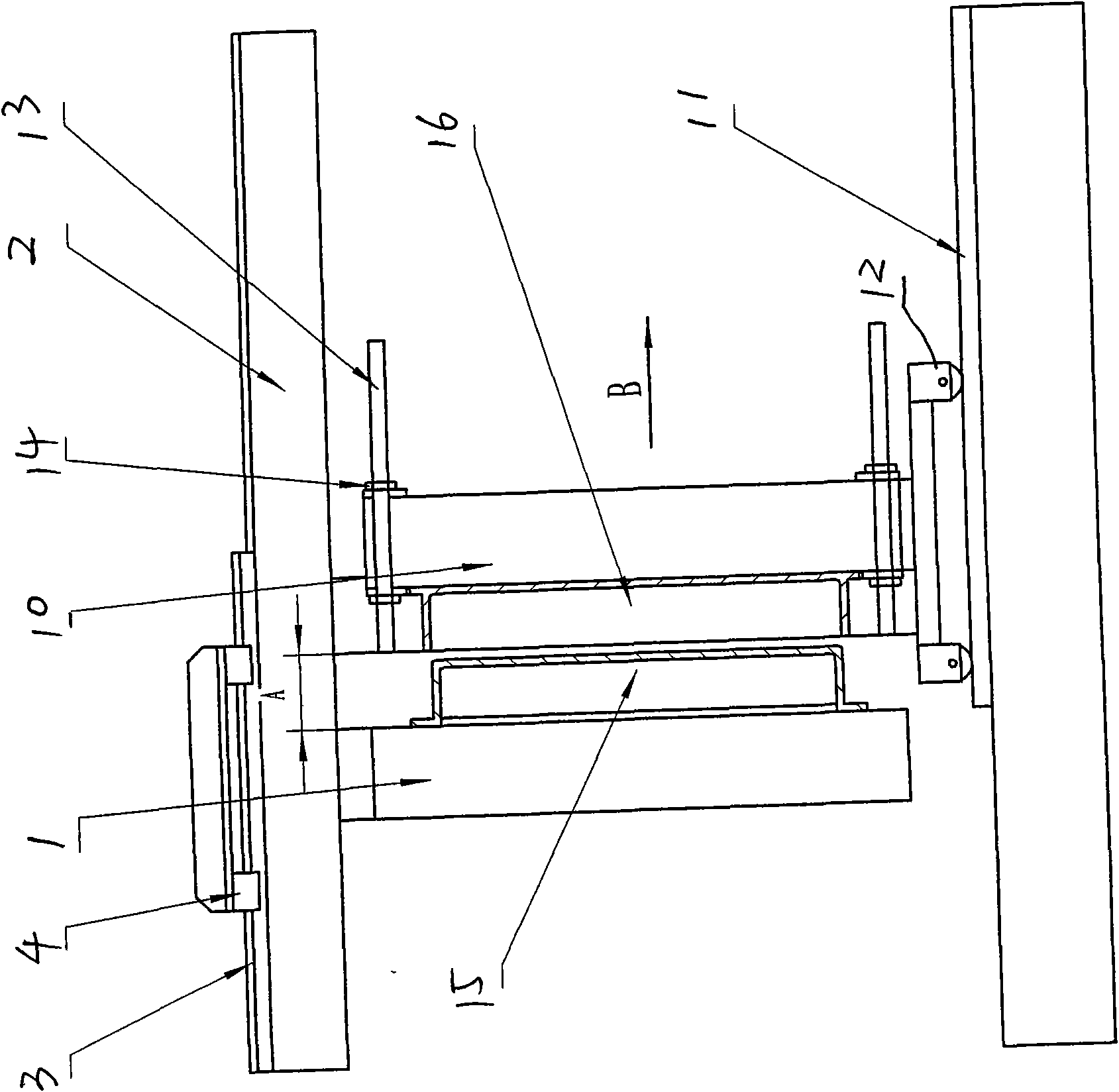

[0011] Such as figure 1 , figure 2 , image 3 As shown, the moving formwork 1 is suspended on the top of the frame 2, and a linear guide rail 3 is provided on the crosspieces on both sides of the top of the frame, and a linear guide rail seat 4 is provided on the linear guide rail, and an "I"-shaped fixing frame is provided on the top of the moving formwork 5. The horizontal frame of the fixed frame is on the guide rail seats on both sides of the frame. There is also a synchronous shaft 6 on the moving template. There are synchronous gears 7 at both ends of the synchronous shaft. The racks 8 are meshed; an encoder 9 is fixed on the synchronous shaft. The suspended formwork is driven by a drive cylinder. The suspended formwork moves along the linear guide rail, with higher operating precision, faster operating speed, lower power consumption, and energy saving. Solid formwork 10 is supported on the support guide rail 11 of frame bottom both sides; Solid formwork bottom is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com