Locking mechanism of clamp type double-template full-automatic foamed plastic forming machine

A technology of locking mechanism and foam plastics, which is applied in the field of locking mechanism, can solve problems such as parting surface change, energy consumption, and influence on the accuracy of finished products, so as to increase the sealing performance, ensure the locking of the mold, and ensure that the mold clamping position is not fixed. change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

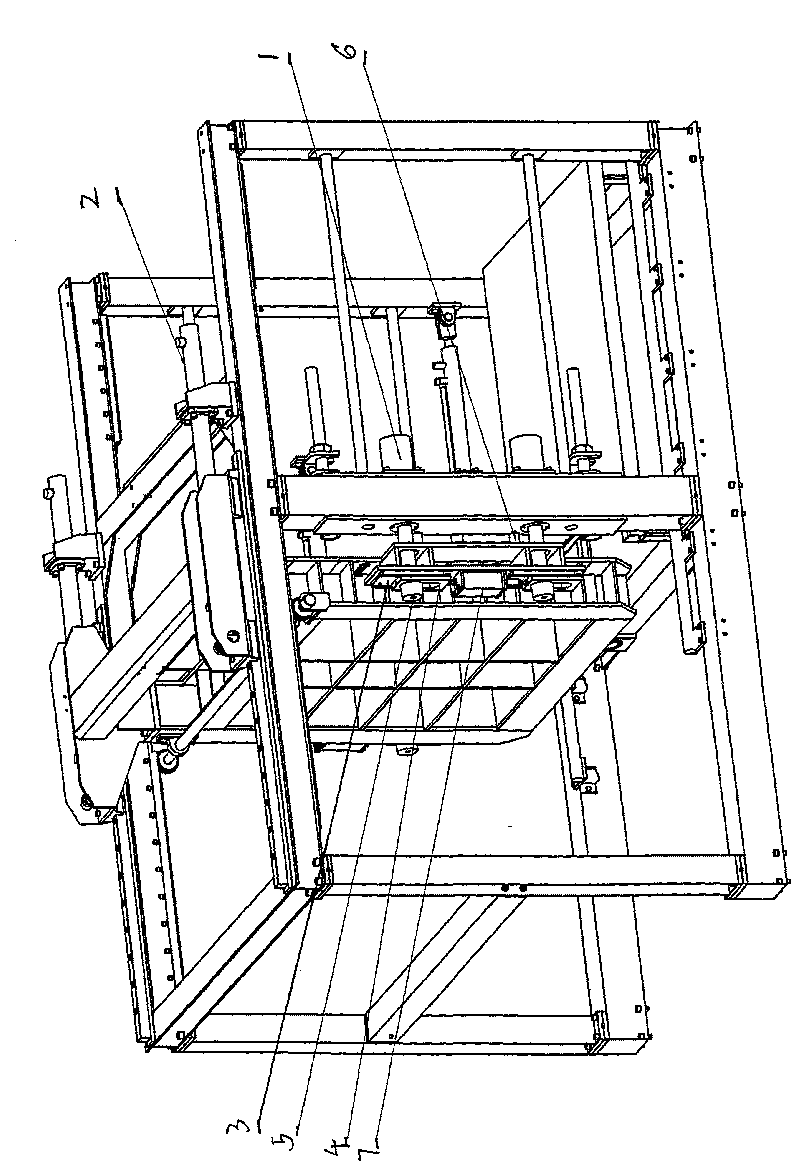

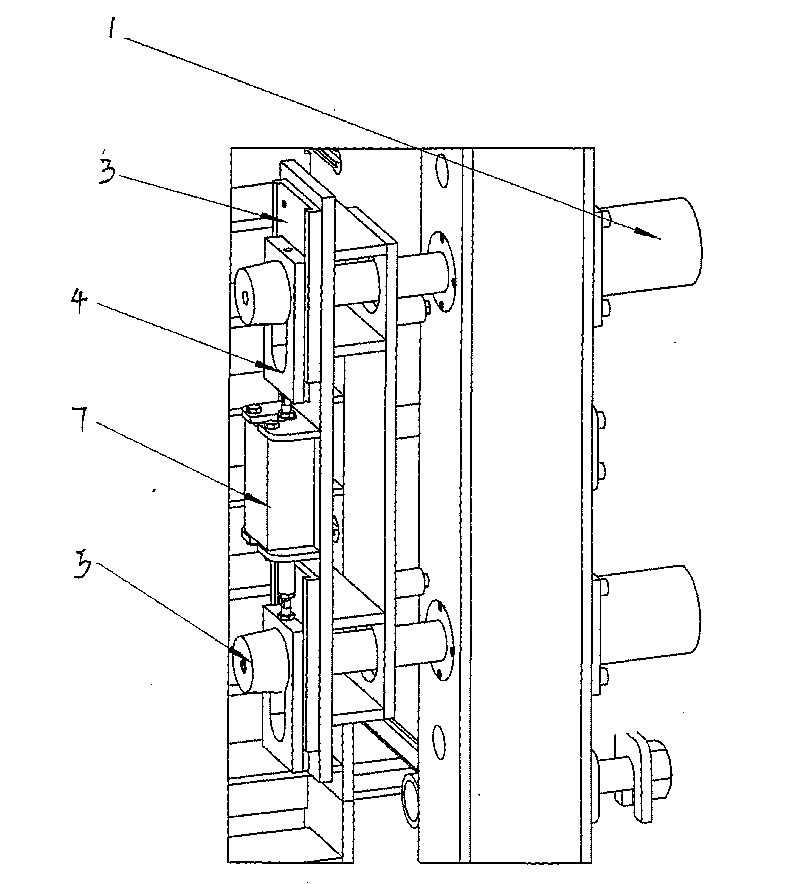

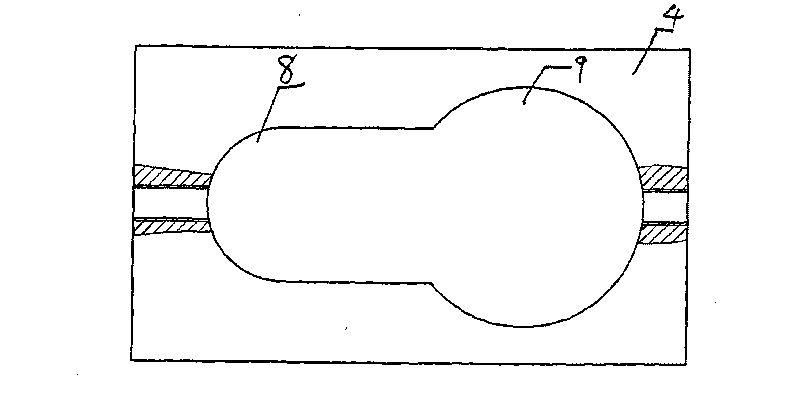

[0019] like Figure 1-Figure 5 As shown, the micro-movement cylinder locking mechanism of the clamp-type two-platen automatic foam plastic molding machine includes 4 locking cylinders 1 and 2 driving cylinders 2, the locking cylinder drives the locking mechanism, and the locking mechanism includes a lock Tightly insert the plate base 3, fix the lock insert plate 4 on the lock insert plate base, the lock insert plate is provided with the locking head 5, and the lock insert plate connects insert plate cylinder 7; figure 1 There is also a mold positioning adjustment device 6 in the middle. A flashboard cylinder simultaneously controls the locking flashboards on both sides; the locking flashboard is provided with two sliding holes 8 and 9 of different sizes. After adjusting the mold loading positioning adjustment device, use the micro-movement cylinder locking mechanism to lock the template, and the mold clamping force is increased by 20% compared with the traditional model, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com