Camshaft adjuster comprising a locking mechanism

A camshaft adjuster and locking device technology, which is applied to valve devices, machines/engines, mechanical equipment, etc., can solve the problem that the control time does not match the specified value, the unstable position of the camshaft adjuster, the increase of wear, and the inability to provide hydraulic medium. enough pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

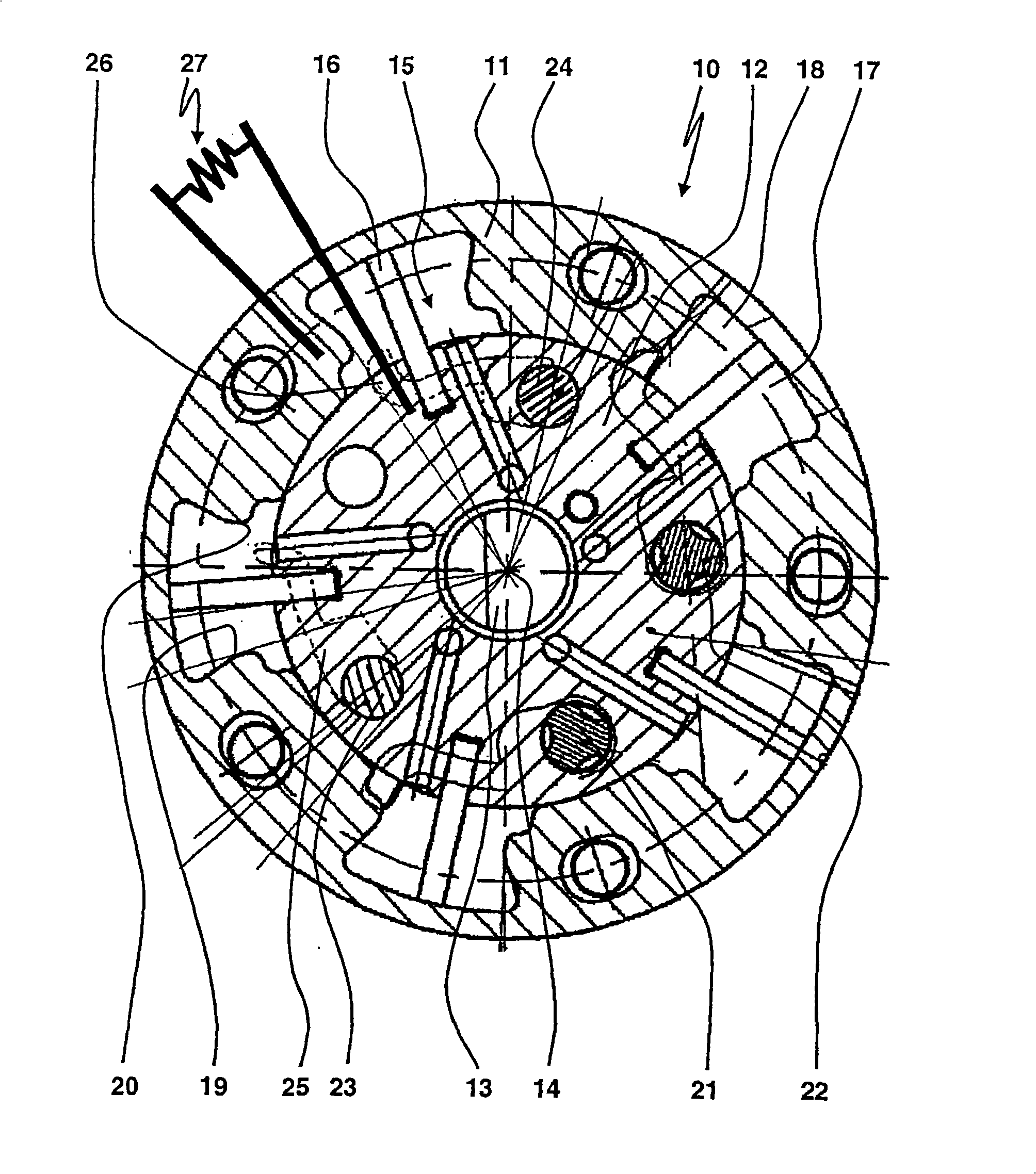

[0028] figure 1 A camshaft adjuster 10 for an internal combustion engine is shown, in which during the adjustment movement of the camshaft adjuster 10, the transmission member 11 can be twisted with respect to the driven member 12 around a rotating shaft 14 oriented perpendicular to the plane of the drawing, The transmission part is connected to the sprocket in a torsion-proof connection and is driven by a control chain, for example, the driven part is connected to the camshaft 13 in a torsion-proof connection, for example. The transmission part 11 is formed with working chambers 15 (here, five), which are restricted by the transmission part 11 radially outward and in two circumferential directions and restricted by the outer shell surface of the driven part 12 radially inward. The blade 16 of the transmission member 11 divides the working chamber 15 into the chamber 17 and the chamber 18. With the aid of the former, the camshaft adjuster 10 is adjusted in the direction of the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com