Pulley frame for aircraft slat rails

A pulley frame and slat technology, applied in the field of pulley frames, can solve the problems that the position of the bolts cannot be fixed and locked, and the eccentric bushing can not be adjusted at the same time, so as to achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, so as to more clearly connect the inventive principle and beneficial technical effects of the present invention.

[0080] Explanation of terms used in this article:

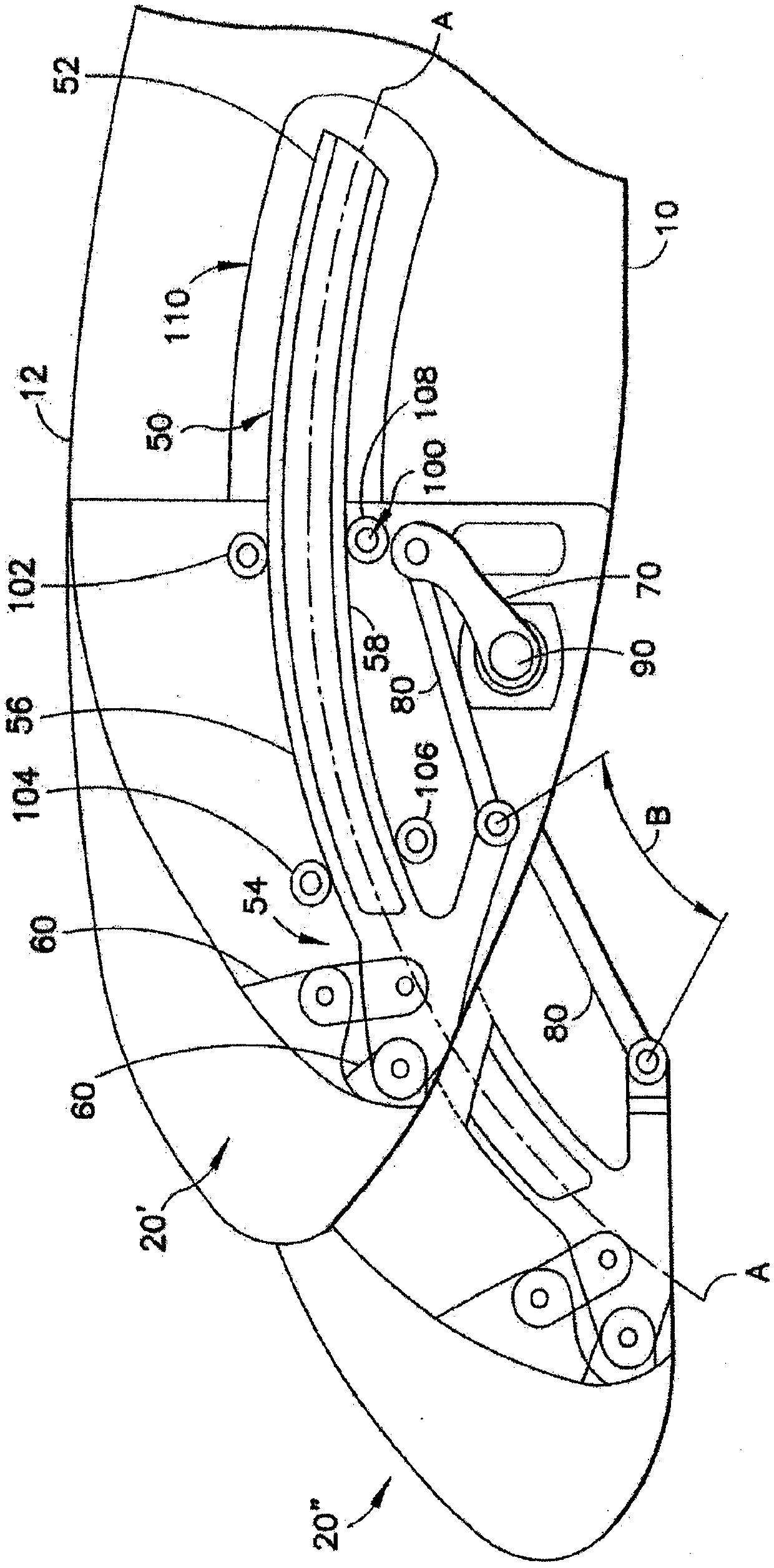

[0081] exist Figure 4 The top of the slat slide rail 9 is called upper;

[0082] exist Figure 4 The bottom of the slat slide rail 9 is called the bottom;

[0083] Along the longitudinal direction of the slat slide rail 9, adjacent to the leading edge of the slat is referred to as the front;

[0084] Along the longitudinal direction of the slat rail 9, relative to the leading edge of the slat is referred to as rear.

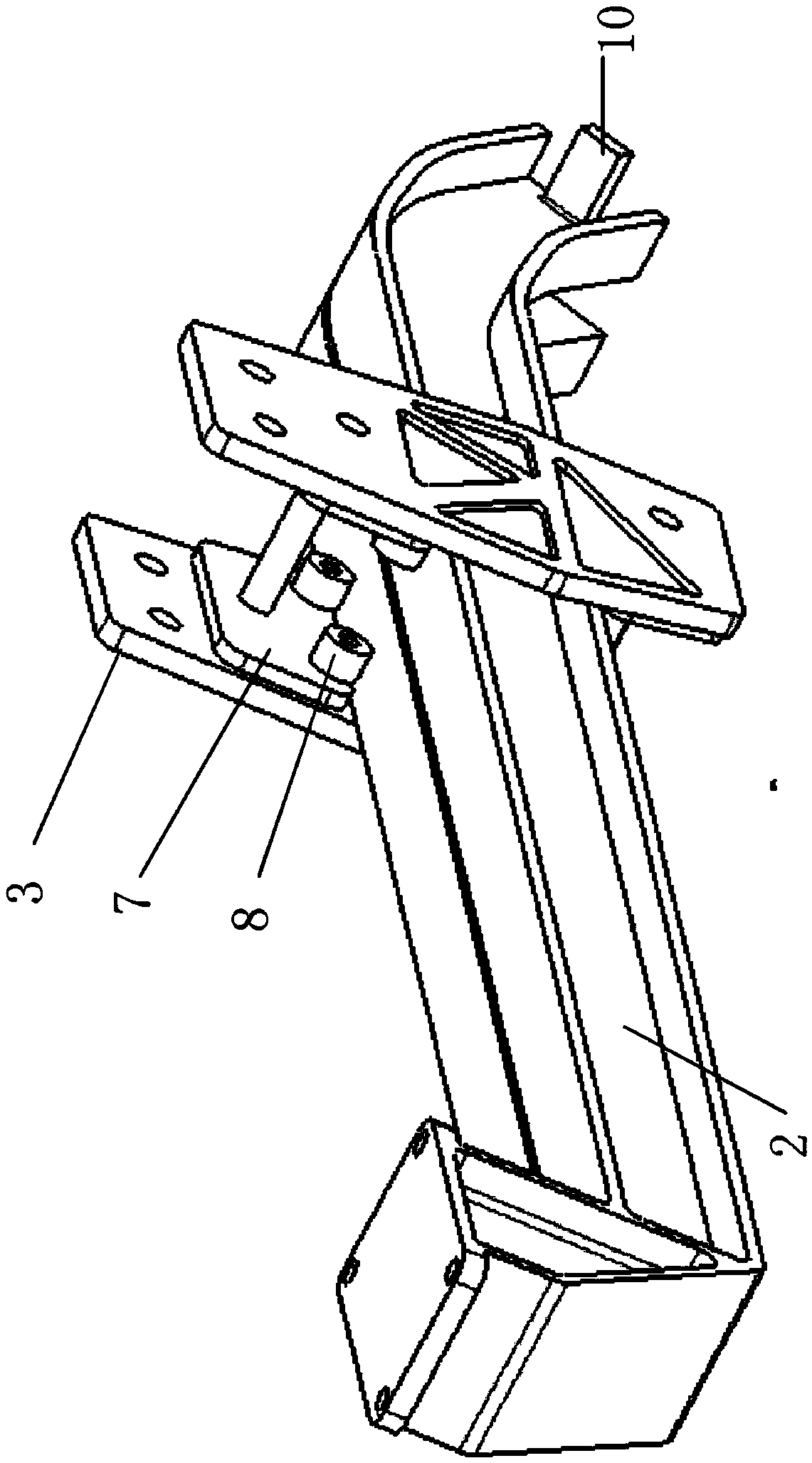

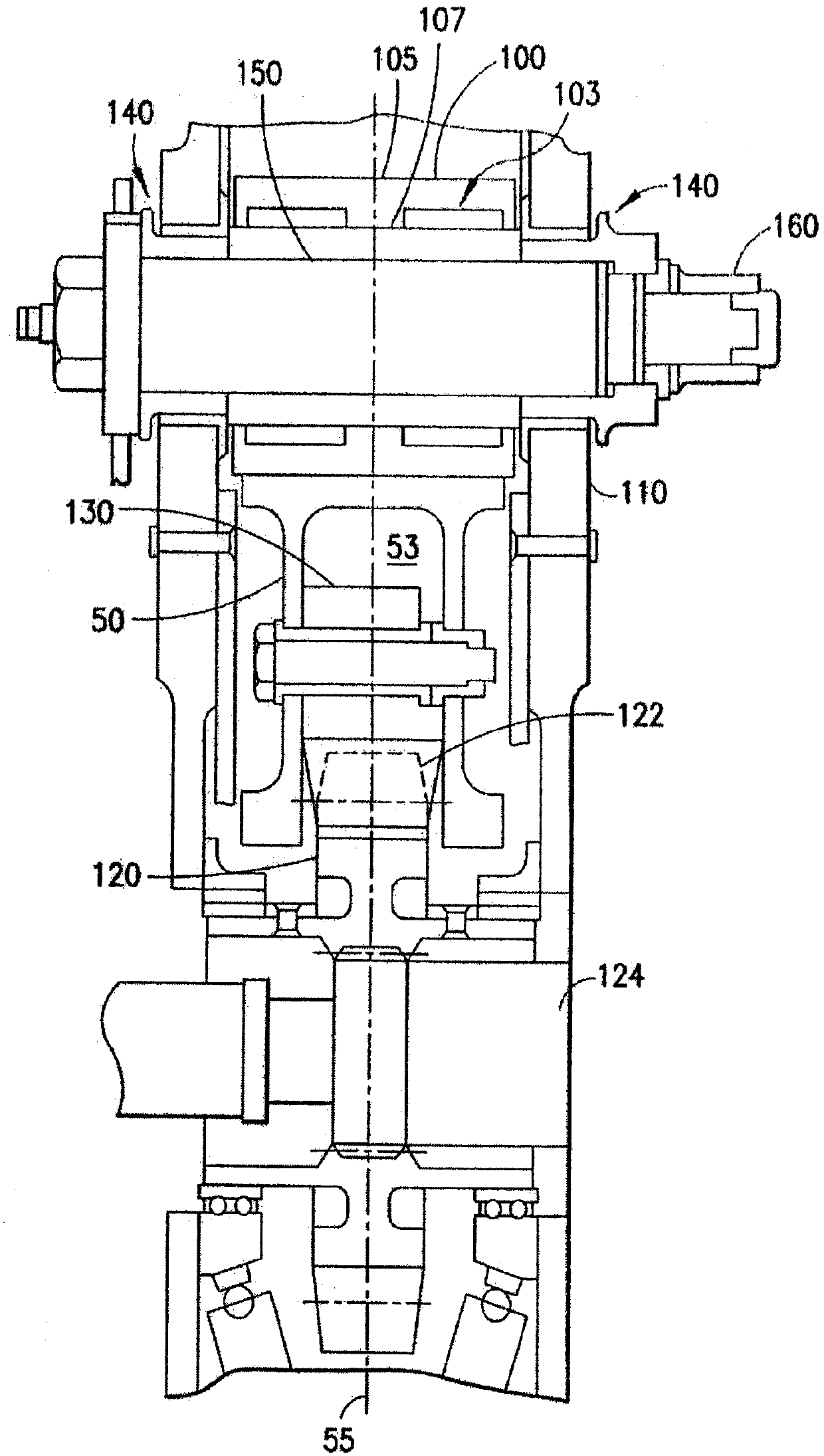

[0085] like Figure 4 As shown, it shows the structure of the pulley frame 10 and the slat slide rail 9 according to the present invention and the mating relationship after the two are assembled. The pulley frame 10 includes a pair of reinforced bulkheads 1 and two pairs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com