Matched mould locking mechanism of hollow plastic forming machine

A technology of locking mechanism and forming machine, which is applied to hollow objects, other household appliances, household appliances, etc., which can solve the problems of difficulty in processing and installation, poor movement stability, and large number of parts, so as to achieve convenient installation and maintenance and save energy. Material, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

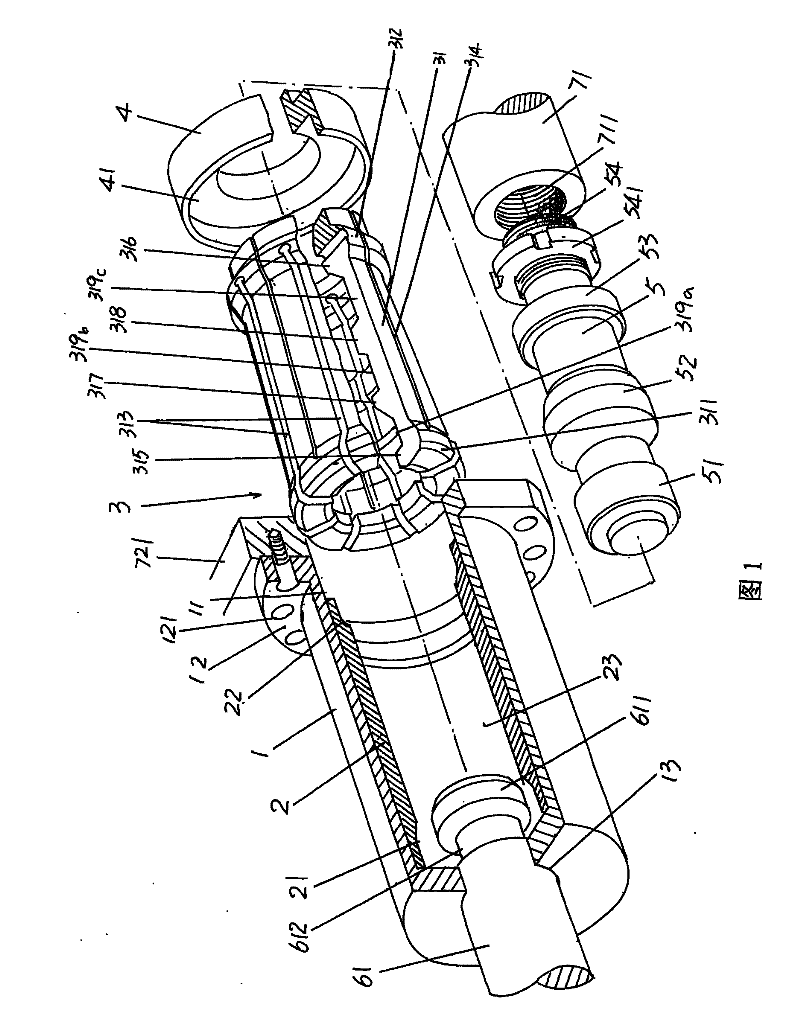

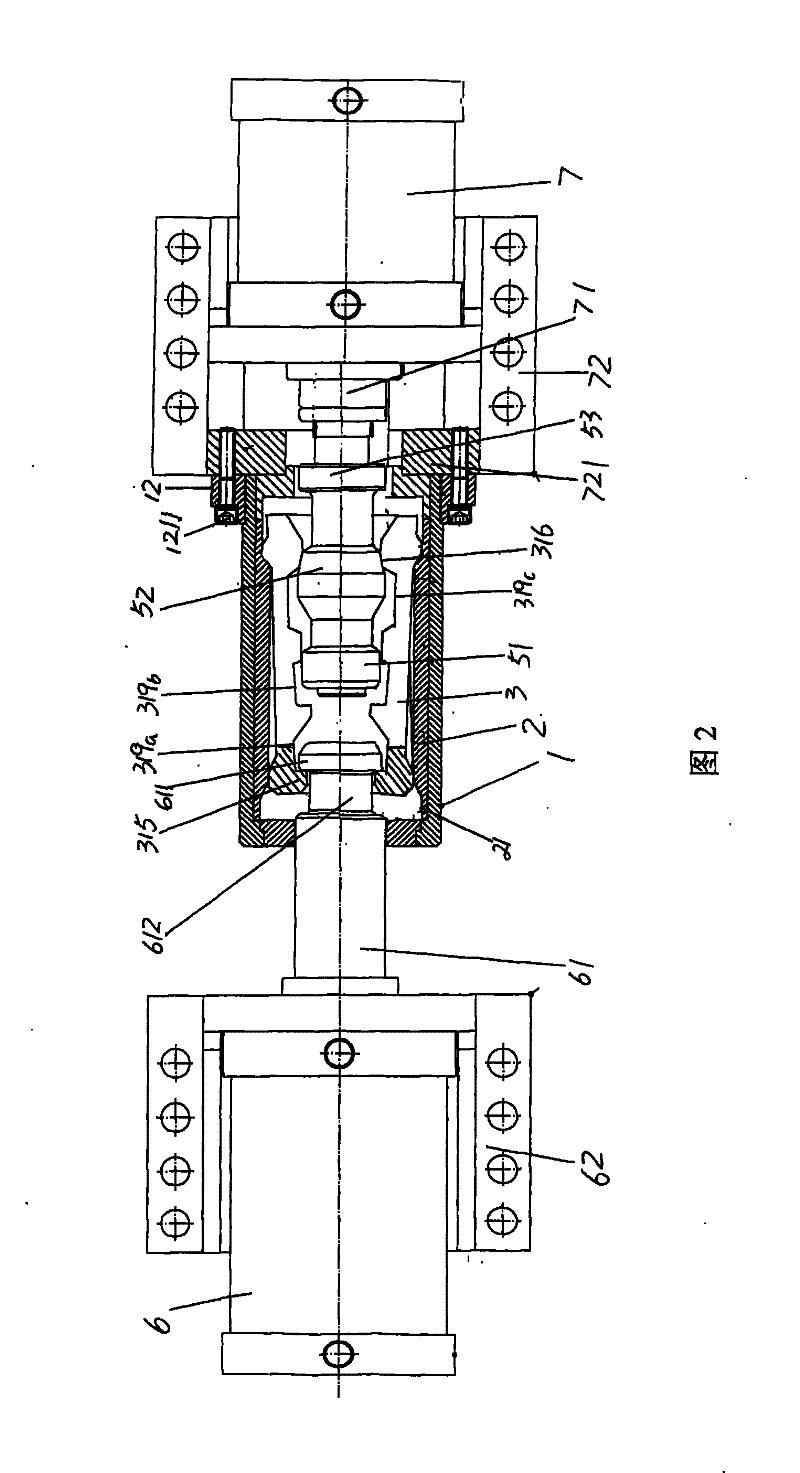

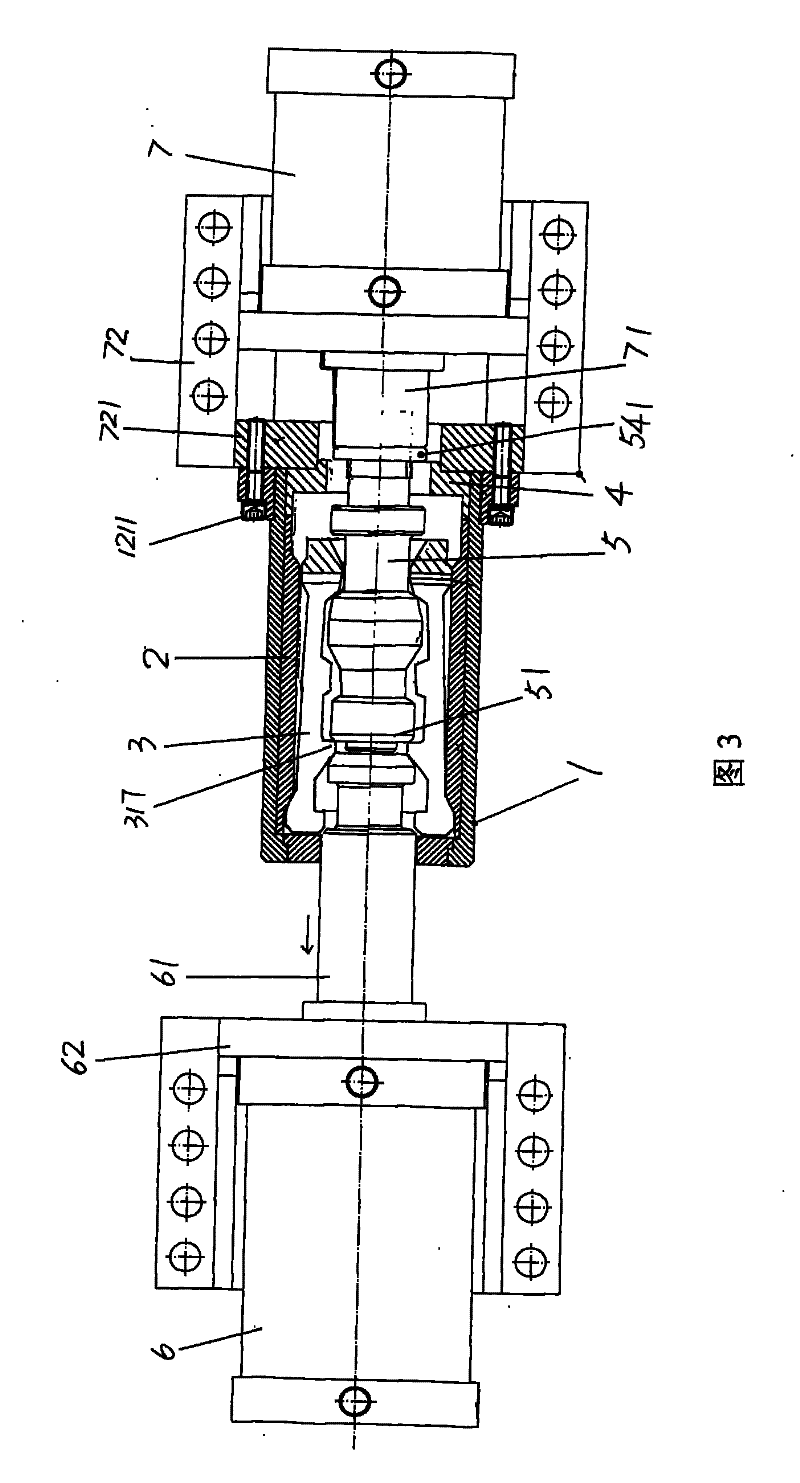

[0023] Please refer to Fig. 1, the fixed cover 1 of a tubular body is shown among the figure, take the position state shown in Fig. 1 as example at present, the central region of the left end of this fixed cover 1 offers a clamping oil cylinder column hole 13, In order to be used for protruding into or withdrawing from the top end of the first cylinder column 61 of the clamping cylinder 6 shown in Fig. 2 to Fig. 4 and having the same structure as the prior art such as the above-mentioned CN2705301Y, the It can be seen that a lock pin 611 is formed at the top end of the first cylinder column 61, and a neck with a diameter obviously smaller than that of the first cylinder column 61 is formed between the pin pin 611 and the cylinder column body of the first cylinder column 61. 612. When the mold is to be clamped and the mold is locked, then the lock pin 611 of the first cylinder column 61 enters the fixed sleeve 1 , otherwise it exits the fixed sleeve 1 . A mating flange 12 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com