Ceramic flame-retardant and fireproof silicone rubber and preparation method thereof

A ceramicized flame retardant and silicone rubber technology, applied in the field of flame retardant and refractory materials, can solve the problems of poor flame retardant performance and processing performance, poor thermal stability of ammonium polyphosphate, low mechanical properties of ceramic body, etc., and improve the poor compatibility. , Excellent electrical insulation and fire resistance, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

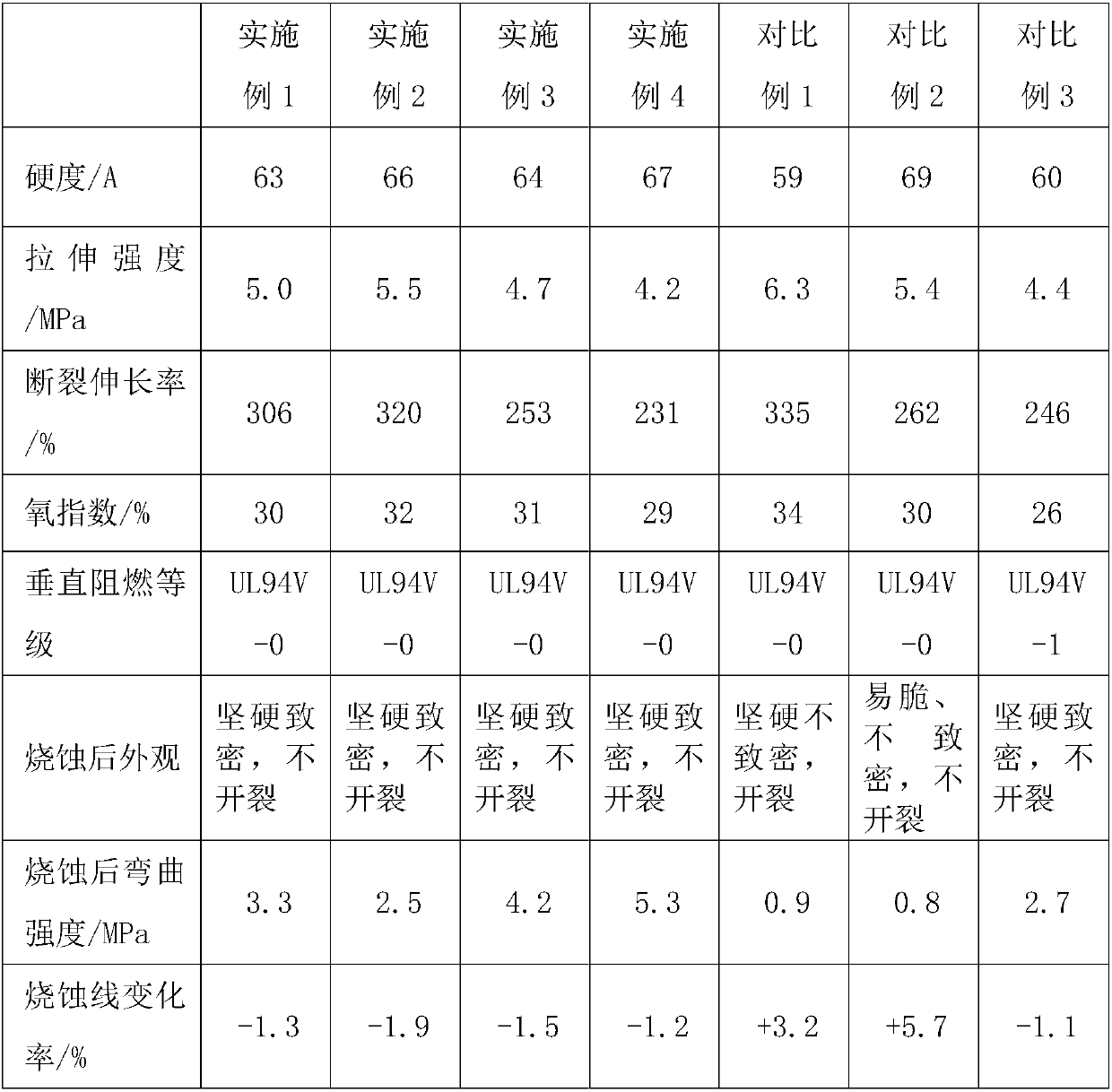

Examples

Embodiment 1

[0039] The components in parts by mass are as follows: 80 parts of methyl vinyl silicone rubber with a molecular weight of 600,000 and a vinyl content of 0.2%, 20 parts of methyl vinyl silicone rubber with a molecular weight of 450,000 and a vinyl content of 0.05%. Surface area is 200m 2 30 parts of gas-phase hydrophilic silica per g, 40 parts of aluminum hydroxide with a particle size of 2 μm, 20 parts of low-melting glass powder with a melting point of 500 ° C, 40 parts of sericite powder with a particle size of 10 μm, and hydroxyl silicone oil with a viscosity of 25 cP 10 parts, 5 parts of hexamethyldisilazane, 1 part of alcohol-modified chloroplatinic acid with a platinum content of 1%, 2 parts of 2,4-dichlorobenzoyl peroxide.

[0040] The preparation method of vitrified refractory silicone rubber is as follows:

[0041] a. First mix 40 parts of aluminum hydroxide, 20 parts of low-melting point glass powder and 40 parts of sericite powder with a high-speed disperser, then...

Embodiment 2

[0047] The components in parts by mass are as follows: 90 parts of methyl vinyl silicone rubber with a molecular weight of 650,000 and a vinyl content of 0.05%, 10 parts of methyl vinyl silicone rubber with a molecular weight of 500,000 and a vinyl content of 3%. Surface area is 150m 2 40 parts of gas-phase hydrophilic silica per g, 30 parts of aluminum hydroxide with a particle size of 5 μm, 15 parts of low-melting glass powder with a melting point of 400 ° C, 30 parts of sericite powder with a particle size of 20 μm, and a viscosity of 28 cP 12 parts of hydroxyl silicone oil, 4 parts of hexamethyldisilazane, 1.2 parts of the reaction complex of triphenyl phosphite and chloroplatinic acid (the mass fraction of platinum is 5%), 2,4-dichlorobenzyl peroxide Acyl 2 parts.

[0048] The preparation method of vitrified refractory silicone rubber is as follows:

[0049] a. First mix 30 parts of aluminum hydroxide, 15 parts of low-melting point glass powder and 30 parts of sericite ...

Embodiment 3

[0055] The components in parts by mass are as follows: 80 parts of methyl vinyl silicone rubber with a molecular weight of 650,000 and a vinyl content of 0.05%, 20 parts of methyl vinyl silicone rubber with a molecular weight of 500,000 and a vinyl content of 3%. Surface area is 380m 2 20 parts of gas-phase hydrophilic silica per g, 50 parts of aluminum hydroxide with a particle size of 10 μm, 25 parts of low-melting glass powder with a melting point of 450 ° C, 50 parts of sericite powder with a particle size of 20 μm, and a viscosity of 30 cP 10 parts of hydroxyl silicone oil, 6.5 parts of hexamethyldisilazane, 1 part of platinum vinyl tetramethyldisiloxane complex (the mass fraction of platinum is 5%), 2,5-dimethyl-2, 2 parts of 5-bis(t-butylperoxy)hexane.

[0056] The preparation method of vitrified refractory silicone rubber is as follows:

[0057] a. First mix 50 parts of aluminum hydroxide, 25 parts of low-melting glass powder and 50 parts of sericite powder with a hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com