Flame-retardant hard polyurethane thermal-insulation foam material and preparation method thereof

A technology of rigid polyurethane and thermal insulation foam, which is applied in the fields of polyurethane foam material and its preparation, rigid polyurethane thermal insulation foam material and its preparation, and can solve the problems of mechanical property degradation, unspecified material thermal conductivity and closed cell ratio , the maximum compressive strength is only 0.17Mpa, etc., achieving the effects of excellent flame retardant performance, good self-extinguishing property and good compression performance

Active Publication Date: 2015-08-12

SHANGHAI JIAO TONG UNIV

View PDF10 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

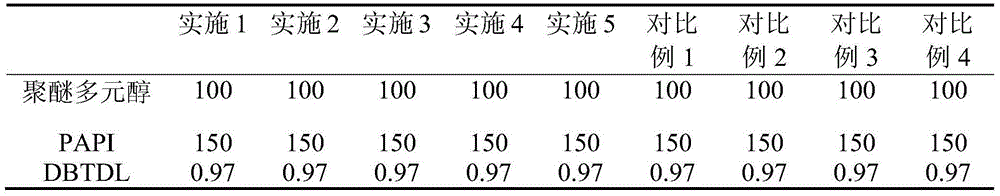

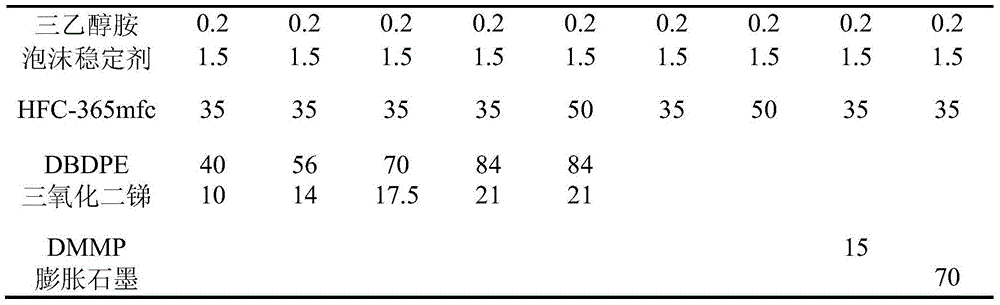

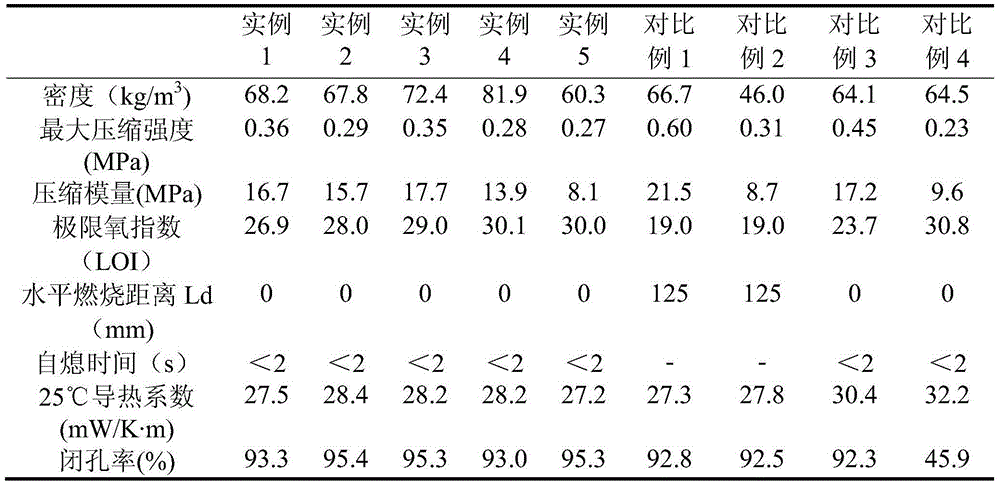

[0005] In terms of literature: Sung Hee Kim et al. (Kim S.H., H.Lim and B.K.Kim.Effects of initiator type in rigid polyurethane foams. Polymer Engineering & Science. 2008.48 (8): 1518-1523) take HFC-365mfc as blowing agent, prepare The obtained density is between 60~80kg/m 3 The rigid polyurethane foam material has a thermal conductivity of 0.022-0.024W/mK. However, since no flame retardant is added to the system, the limiting oxygen index of the material is less than 20; Anzhen Zhang et al. (Zhang A.et al.Synergistic effects of Hydroxides and dimethyl methylphosphonate on rigid halogen-free and flame-retarding polyurethane foams.Journal of Applied Polymer Science.2013.128(1):347-353) studied the compound flame retardancy of DMMP and aluminum hydroxide on rigid polyurethane foam It is found that when the mass fraction of DMMP is 10%, and the mass fraction of aluminum hydroxide is greater than 45%, the oxygen index of the foam material is greater than 30, and at this time the mechanica

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a flame-retardant hard polyurethane thermal-insulation foam material and a preparation method thereof, and relates to the field of polymer materials. The foam material is composed of the following components in parts by weight: 100 parts of polyether polyol, 140 to 160 parts of polymethylene polyphenyl polyisocyanate, 30 to 50 parts of physical foaming agent HFC-365mfc, 1.5 to 5 parts of foam stabilizer, 1 to 3 parts of catalyst, and 50 to 105 parts of flame retardant. The preparation method comprises the following steps: drying polyether polyol, polymethylene polyphenyl polyisocyanate, and flame retardant powder, saving the processed materials for later use at a room temperature; taking polymethylene polyphenyl polyisocyanate as the component A, mixing other components, taking the mixture as the component B, carrying out a polymerization and foaming treatment to obtain a casting mould blank; after demoulding, and aging obtained casting mould blank to obtain the foam material with a density in a range of 60 to 80 kg/m3. The prepared foam material has the advantages of high flame retardant performance, excellent thermal insulation property, and good mechanical property. Furthermore, an III-generation HFCs type ODP-free environment-friendly foaming agent and environment-friendly flame retardant are adopted.

Description

technical field [0001] The invention relates to a polyurethane foam material in the technical field of polymer materials and a preparation method thereof, in particular to a rigid polyurethane thermal insulation foam material with high flame retardancy and low thermal conductivity and a preparation method thereof. Background technique [0002] Due to its excellent comprehensive performance, especially its low thermal conductivity, rigid polyurethane foam has become a thermal insulation material widely used in many fields such as construction, shipbuilding, chemical industry, and transportation. However, rigid polyurethane foam itself is flammable, and its limiting oxygen index is usually only about 18, and it will produce a lot of smoke and harmful gases after burning. Therefore, using pure polyurethane rigid foam as insulation material has great safety hazards in use. Therefore, how to improve the flame retardancy of rigid polyurethane foam while maintaining its good therma...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08G18/76C08G18/48C08G18/24C08G18/18C08J9/14C08K5/03C08K3/22

CPCC08G18/165C08G18/1825C08G18/246C08G18/4883C08G18/7664C08J9/146C08J2203/142C08J2375/08C08K3/2279C08K5/03C08G2110/0025C08G2110/0058

Inventor 孙军坤蔡志祥靳蔷薇俞炜张洪斌

Owner SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com