Ethylene propylene diene terpolymer low-smoke zero-halogen flame retardant soft rubber

A technology of EPDM rubber and soft rubber compound is applied in the field of EPDM low-smoke halogen-free flame retardant soft compound, which can solve the problems of poor self-extinguishing performance, large amount of flame retardant and high hardness. To achieve good self-extinguishing and hardness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

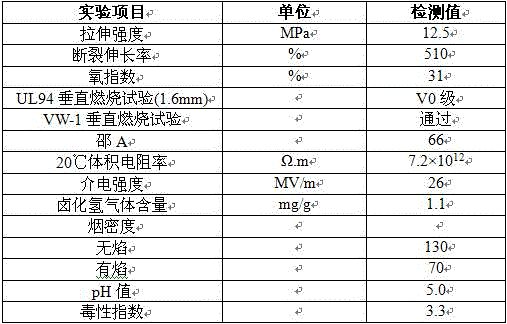

Embodiment 1

[0018] Example 1: A EPDM low-smoke, halogen-free, flame-retardant soft rubber material is made of the following raw materials in parts by weight: 100 parts of EPDM rubber, 50 parts of aluminum hydroxide, 50 parts of magnesium hydroxide, 20 parts of microencapsulated ammonium polyphosphate, 15 parts of microencapsulated red phosphorus.

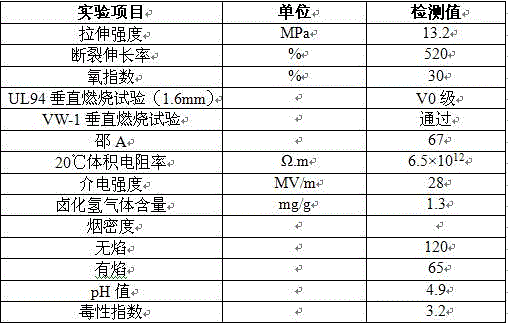

Embodiment 2

[0019] Example 2: A soft low-smoke, halogen-free, flame-retardant EPDM rubber compound made of the following raw materials in parts by weight: 100 parts of EPDM rubber, 80 parts of magnesium hydroxide, 15 parts of zinc borate, phosphoric acid 15 parts of triphenyl ester, 15 parts of pentaerythritol phosphate, 10 parts of zinc borate, 15 parts of microencapsulated red phosphorus.

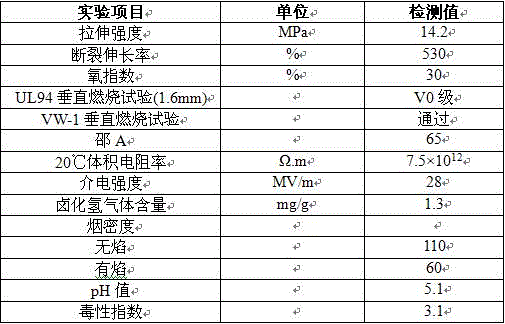

Embodiment 3

[0020] Example 3: An EPDM low-smoke, halogen-free, flame-retardant soft rubber material is made of the following raw materials in parts by weight: 100 parts of EPDM rubber, 100 parts of inorganic flame retardant, phosphorus nitrogen flame retardant 20 parts, 20 parts of synergistic flame retardant, 16 parts of plasticizer, 2.5 parts of antioxidant, 2 parts of zinc oxide, 3 parts of modifier, 1 part of stearic acid, 1.5 parts of silicone powder, 2.5 parts of carbon black , 1 part of sulfur, 2 parts of vulcanization accelerator.

[0021] The inorganic flame retardant is aluminum hydroxide.

[0022] The phosphorus nitrogen flame retardant is 5 parts of melamine and 15 parts of ammonium polyphosphate.

[0023] The synergistic flame retardant is 5 parts of microencapsulated red phosphorus and 15 parts of zinc borate.

[0024] The plasticizer is 3 parts of paraffin oil, 3 parts of cylinder oil, and 10 parts of tricresyl phosphate.

[0025] The antioxidant is 0.5 parts of tetrakis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com