Method of producing flat fibers for plastic woven bags and flexible freight containers by using waste PET (polyethylene terephthalate) bottles

A polyester bottle and plastic woven bag technology, which is applied in the fields of flat yarn, flat yarn for container bags, and plastic woven bags produced from waste polyester bottles, which can solve the problems of flat yarn becoming hard, easy to deform, and low elongation at break. Problems, to avoid easy broken wire, long service life, good anti-aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

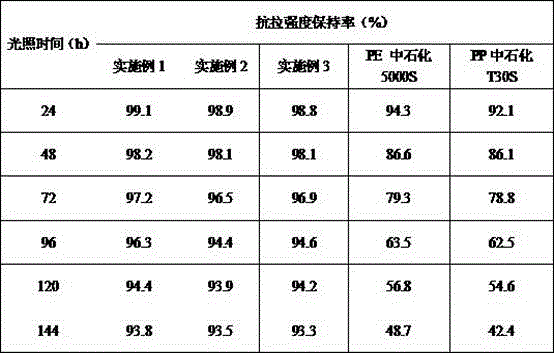

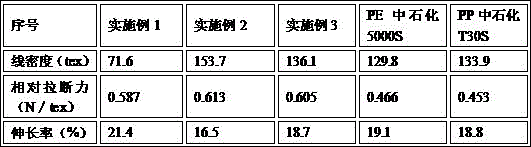

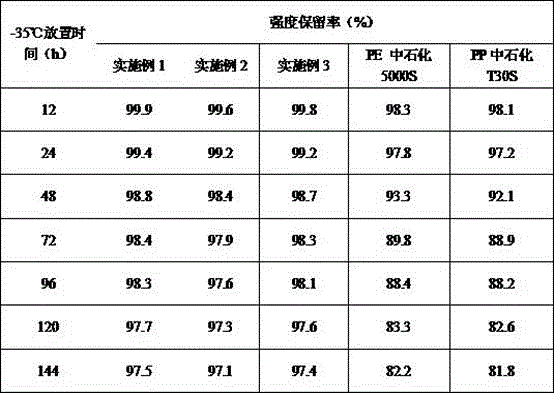

Examples

Embodiment 1

[0038] Embodiment 1, a kind of waste and old polyester bottle produces the method for high-intensity, high-toughness plastic woven bag, container bag flat wire, comprises the following steps:

[0039] (1) Crushing and cleaning steps: cutting and crushing waste polyester plastic bottles and bottle caps into bottle flakes with a diameter of 12mm-14mm, among which the intrinsic viscosity of the polyester bottle flakes is 0.60-0.68dL / g, through a fully automatic ultrasonic cleaning machine, After ultrasonic cleaning in sequence, the ultrasonic frequency is 20kHz, the ultrasonic treatment time is 3 minutes, high-pressure spray cleaning, hot water rinsing at 85°C, air bubbling tap water cleaning, and clean bottle flakes are obtained;

[0040] (2) Crystallization drying: Send the crushed flakes into the vacuum drum device for heating and drying through the feeder, heat to 140°C with heat conduction oil, and dry the crystallization for 6 hours, and use a vacuum pump to continuously eva...

Embodiment 2

[0046] Embodiment 2, a kind of waste and old polyester bottle produces the method for high-intensity, high-toughness plastic woven bag, container bag flat wire, comprises the following steps:

[0047] (1) Crushing and cleaning steps: cutting and crushing waste polyester plastic bottles and bottle caps into bottle flakes with a diameter of 12mm-14mm, among which the intrinsic viscosity of the polyester bottle flakes is 0.60-0.68dL / g, through a fully automatic ultrasonic cleaning machine, After ultrasonic cleaning in sequence, the ultrasonic frequency is 40kHz, the ultrasonic treatment time is 2 minutes, high-pressure spray cleaning, hot water rinsing at 95°C, air bubbling tap water cleaning, and clean bottle flakes are obtained;

[0048] (2) Crystallization drying: Send the crushed flakes into the vacuum drum device for heating and drying through the feeder, heat to 160°C with heat transfer oil, and dry the crystallization for 4 hours, and use a vacuum pump to continuously vacuum ...

Embodiment 3

[0053] Embodiment 3, a kind of waste and old polyester bottle produces the method for high-intensity, high-toughness plastic woven bag, container bag flat wire, comprises the following steps:

[0054] (1) Crushing and cleaning steps: cutting and crushing waste polyester plastic bottles and bottle caps into bottle flakes with a diameter of 12mm-14mm, among which the intrinsic viscosity of the polyester bottle flakes is 0.60-0.68dL / g, through a fully automatic ultrasonic cleaning machine, After ultrasonic cleaning in sequence, the ultrasonic frequency is 50kHz, the ultrasonic treatment time is 1 minute, high-pressure spray cleaning, hot water rinsing at 90°C, air bubbling tap water cleaning, and clean bottle flakes are obtained;

[0055] (2) Crystallization drying: Send the crushed flakes into the vacuum drum device for heating and drying through the feeder, heat to 180°C with heat transfer oil, and dry the crystallization for 3 hours. The negative pressure generated in the dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com