High-flame-resistance filler and preparation method thereof as well as mining high-flame resistance flexible cable made from high-flame-resistance filler

A technology of high flame retardant and filling materials, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of flexible cables such as flame retardant and poor self-extinguishing performance, and achieve excellent electrical performance and low product cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The weight of each component of a high flame retardant filler is:

[0038] Superfine talc 32 kg Light calcium carbonate 30 kg Acrylate rubber 12 kg

[0039] Industrial grade dioctyl sebacate 3 kg Adhesive 1.5 kg Barium stearate 3 kg

[0040] Nanoscale Calcium Oxide 2 kg Silica 1 kg.

[0041] Ultrafine talcum powder is selected from 1250 mesh and above ultrafine talcum powder.

[0042] The preparation method of the above-mentioned high flame-retardant filler is as follows: masticating acrylate rubber and dioctyl sebacate on an internal mixer for 2 to 3 minutes, gradually adding superfine talcum powder, light calcium carbonate, barium stearate and mixing Mixing, adding adhesive and mixing for 3-6 minutes, after the initial dispersion of each component, take out the mixed product, finally add nano-scale calcium oxide and silicon dioxide on the open mill, thin pass 6 times, that is, a high flame retardant stuffing.

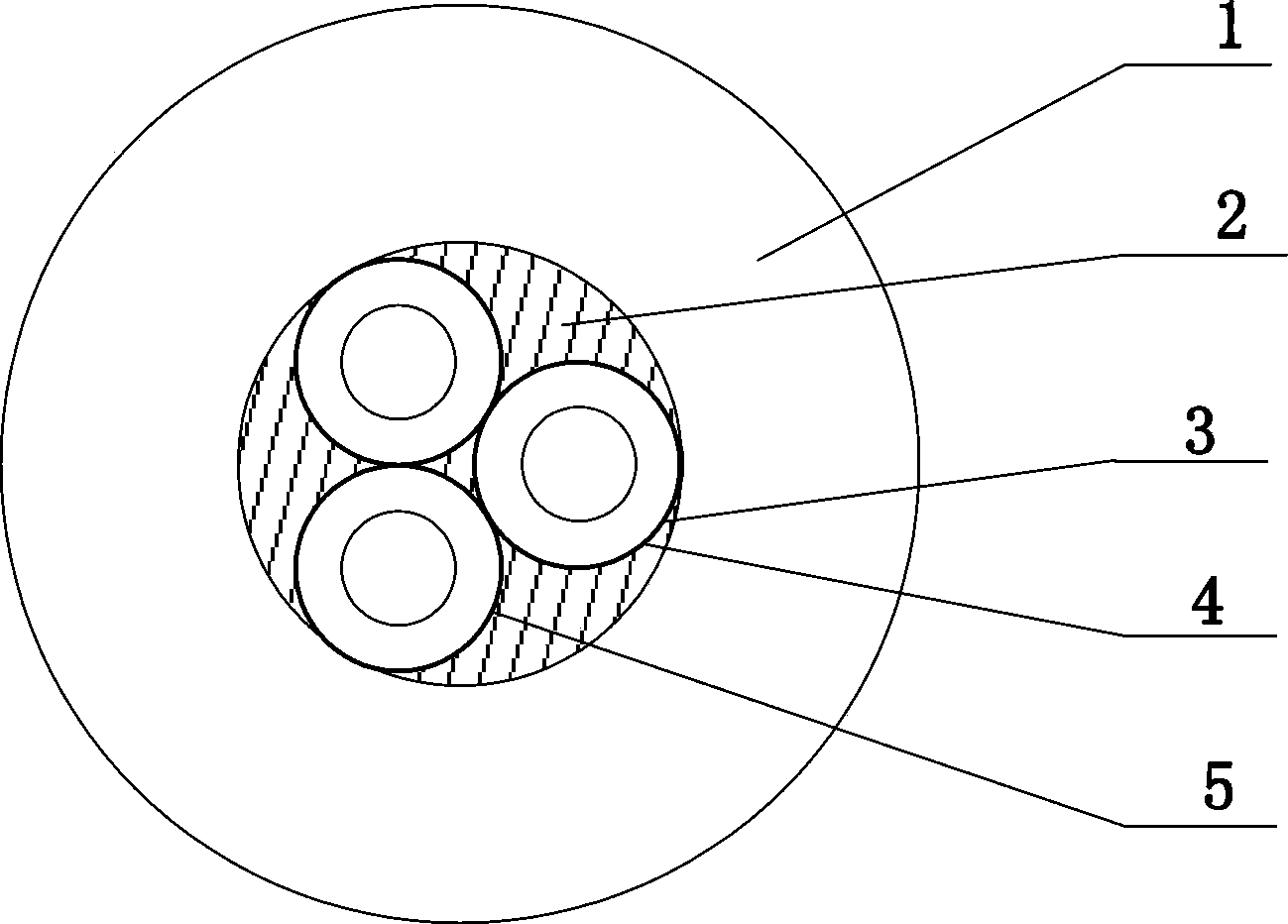

[0043] like figure 1 As shown, a mine-used high f...

Embodiment 2

[0061] The weight of each component of a high flame retardant filler is:

[0062] Superfine talc 38 kg Light calcium carbonate 35 kg Acrylate rubber 15 kg

[0063] Industrial grade dioctyl sebacate 3 kg Adhesive 3.5 kg Barium stearate 8 kg

[0064] Nanoscale Calcium Oxide 5 kg Silica 2 kg.

[0065] Ultrafine talcum powder is selected from 1250 mesh and above ultrafine talcum powder.

[0066] [0034] The preparation method of the above-mentioned high flame-retardant filler is as follows: masticating acrylate rubber and dioctyl sebacate on an internal mixer for 2 to 3 minutes, gradually adding superfine talcum powder, light calcium carbonate, barium stearate and mixing Mixing, adding adhesive and mixing for 3-6 minutes, after the initial dispersion of each component, take out the mixed product, finally add nano-scale calcium oxide and silicon dioxide on the open mill, thin pass 6 times, that is, a high flame retardant stuffing.

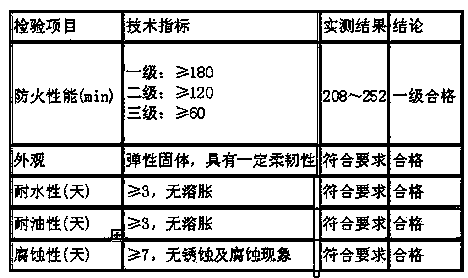

[0067] A high flame-retardant flexible cabl...

Embodiment 3

[0085] The weight of each component of a high flame retardant filler is:

[0086] Superfine talc 28 kg Light calcium carbonate 22 kg Acrylate rubber 5 kg

[0087] Industrial grade dioctyl sebacate 1 kg Adhesive 0.2 kg Barium stearate 1 kg

[0088] Nanoscale Calcium Oxide 0.2 kg Silicon Dioxide 0.2 kg.

[0089] Ultrafine talcum powder is selected from 1250 mesh and above ultrafine talcum powder.

[0090] The preparation method of the above-mentioned high flame-retardant filler is as follows: masticating acrylate rubber and dioctyl sebacate on an internal mixer for 2 to 3 minutes, gradually adding superfine talcum powder, light calcium carbonate, barium stearate and mixing Mixing, adding adhesive and mixing for 3-6 minutes, after the initial dispersion of each component, take out the mixed product, finally add nano-scale calcium oxide and silicon dioxide on the open mill, thin pass 6 times, that is, a high flame retardant stuffing.

[0091] A high flame-retardant flexibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com