High-strength hot rolled steel sheet being free from peeling and excelling in surface and burring properties and process for manufacturing the same

A technology for surface properties and hot-rolled steel sheets, applied in the field of high-strength hot-rolled steel sheets and their manufacturing, can solve the problems of no open scars or tiny cracks, and achieve the effects of excellent surface properties, excellent resistance, and high industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

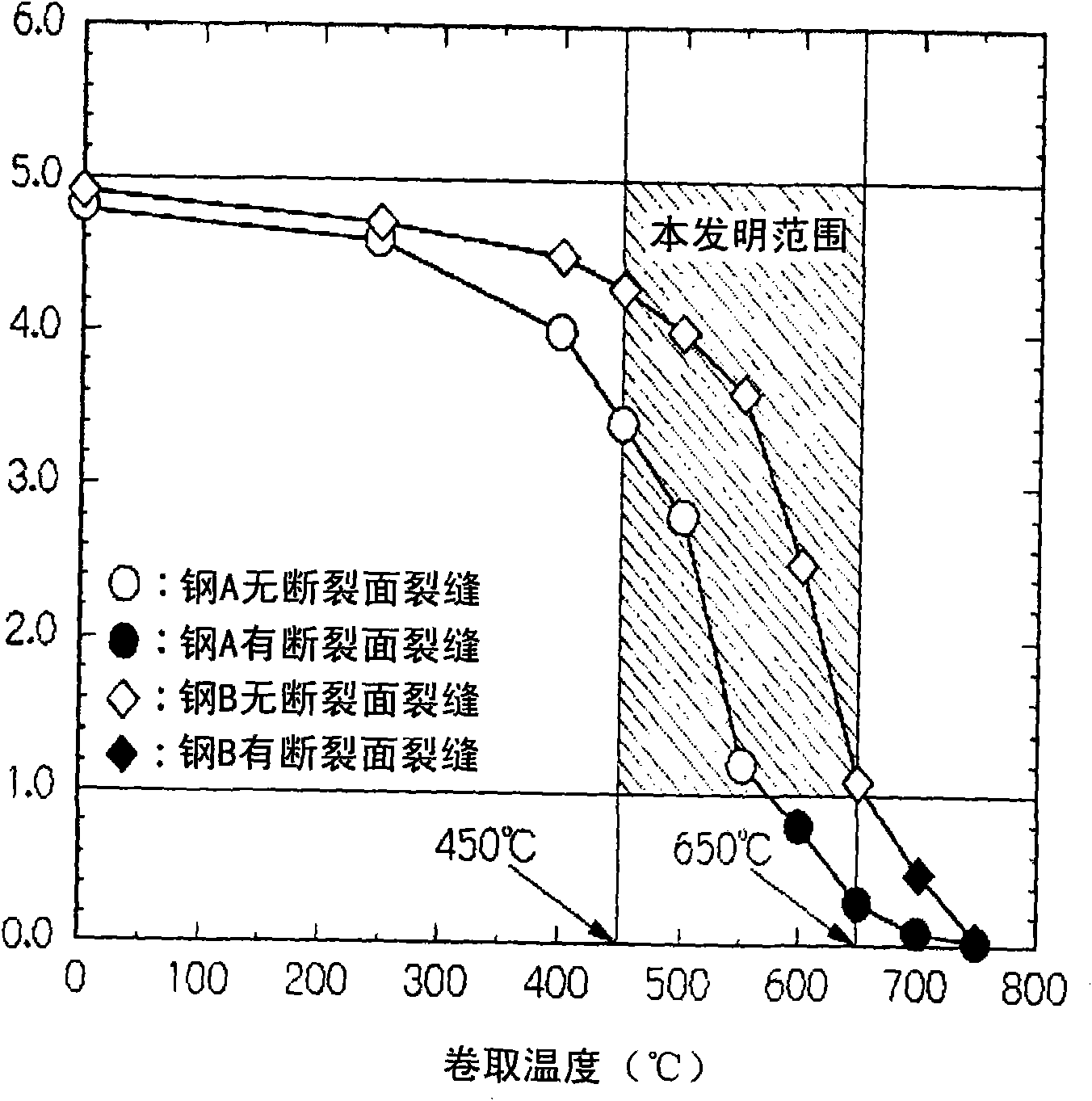

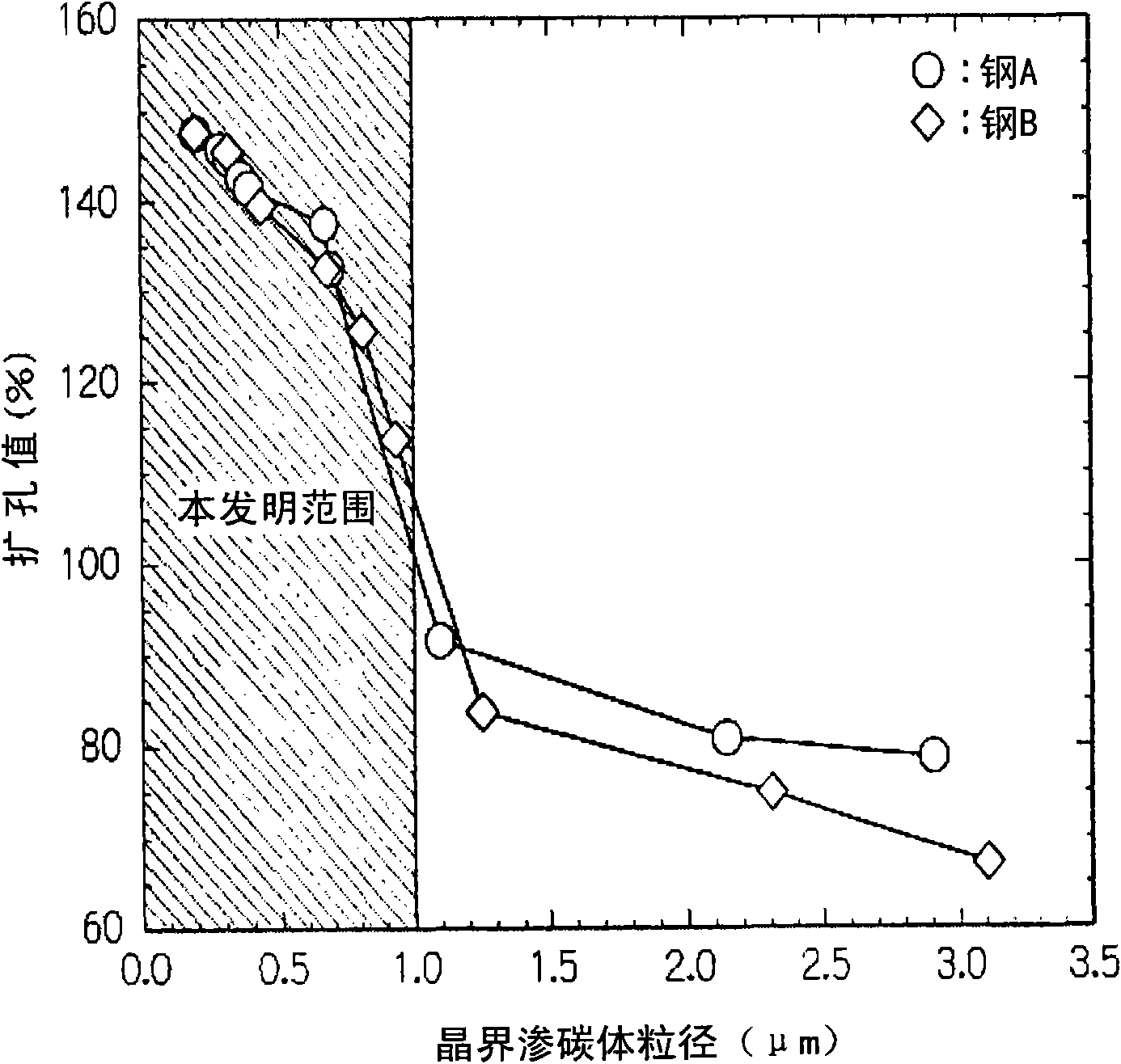

[0242] Hereinafter, the present invention will be further described based on examples.

[0243] The cast sheets a~m with the chemical composition shown in Table 3 are melted in a converter, conveyed or reheated directly after continuous casting, and are pressed down to a plate thickness of 2.0~3.6mm by finishing rolling followed by rough rolling. After the output roller is cooled, it is coiled to make hot-rolled steel plates. More specifically, hot-rolled steel sheets were produced under the production conditions shown in Tables 4 to 7. In addition, the indication of the chemical composition in a table|surface is all mass %. In addition, the balance of the components in Table 3 means Fe and unavoidable impurities, and the underlines in Table 3, Table 4 to Table 7 mean outside the scope of the present invention.

[0244]

[0245]

[0246]

[0247]

[0248]

[0249] Here, "composition" means steel having a composition corresponding to each symbol shown in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com