Flexible display substrate thin film and manufacturing method therefor, and display apparatus

A technology for curved displays and display devices, applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, other household appliances, etc., can solve the problems of weak impact resistance, insufficient impact resistance, cracking during processing and use, etc. Achieve the effect of improving drop and impact resistance, improving mechanical impact capability, and avoiding over-bending defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

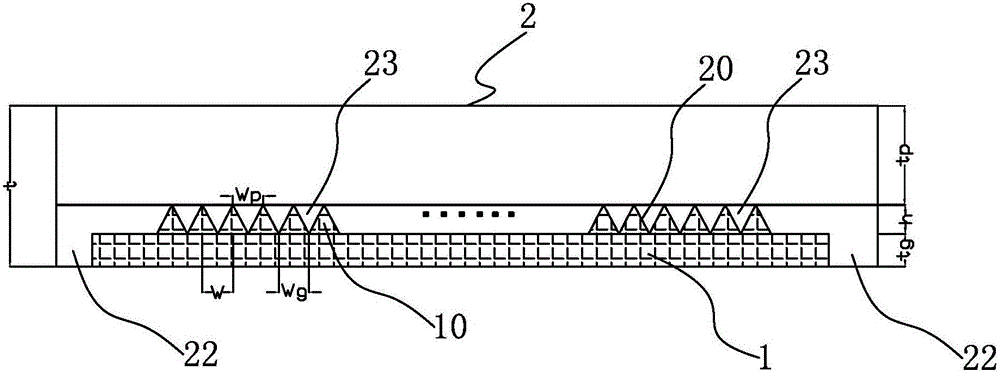

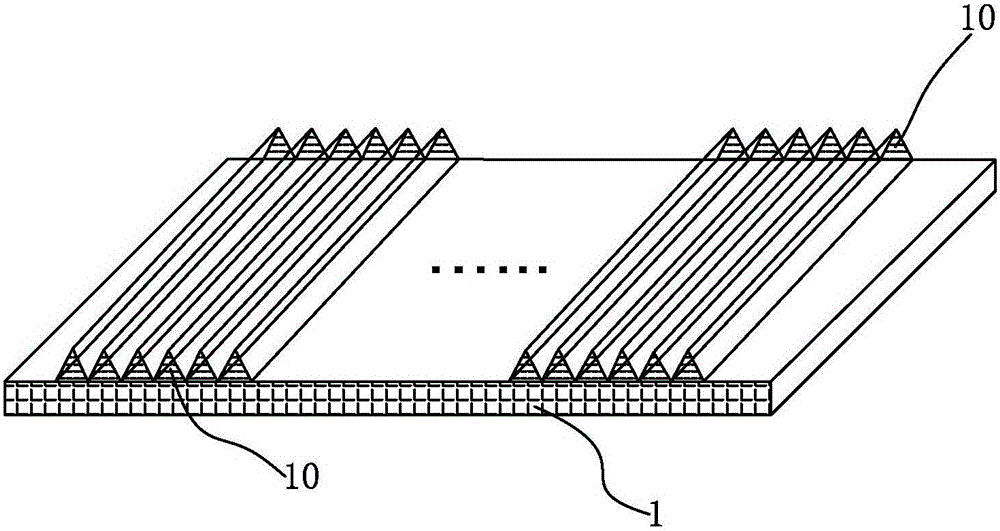

[0061] As a preferred embodiment, the plastic film 2 includes a cover portion 21 opposite to the glass film 1 and two edge portions 22 respectively placed on both sides of the cover portion 21, and the cover portion 21 does not include a concave portion The thickness of the part 20 is less than or equal to 400 μm. When wrapping the glass film 1, the thinner the thickness of the plastic film 2, the better, which can increase the transmittance and be more conducive to bending; as a preferred embodiment, the edge part The width of 22 is greater than 100 μm, the thickness is less than or equal to 600 μm, the thickness of the edge part 22 is equal to the thickness of the plastic film 2 covering part 21 and the thickness of the part of the glass film 1 that does not include the raised part 10, by wrapping the outer edge of the glass film 1 The setting of the edge area can effectively reduce the probability of defects.

[0062] As a preferred embodiment, the thickness of the display ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com