Metal carbide coating covered carbon-based material and preparation method therefor

A metal carbide and carbon-based material technology, which is applied in the field of carbon-based materials covered with metal carbide coating and its preparation, can solve the problem of low bonding strength between coating and substrate, corrosion of reaction products to equipment, and uniform coating. It is easy to operate, the thickness is uniform and controllable, and the performance is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

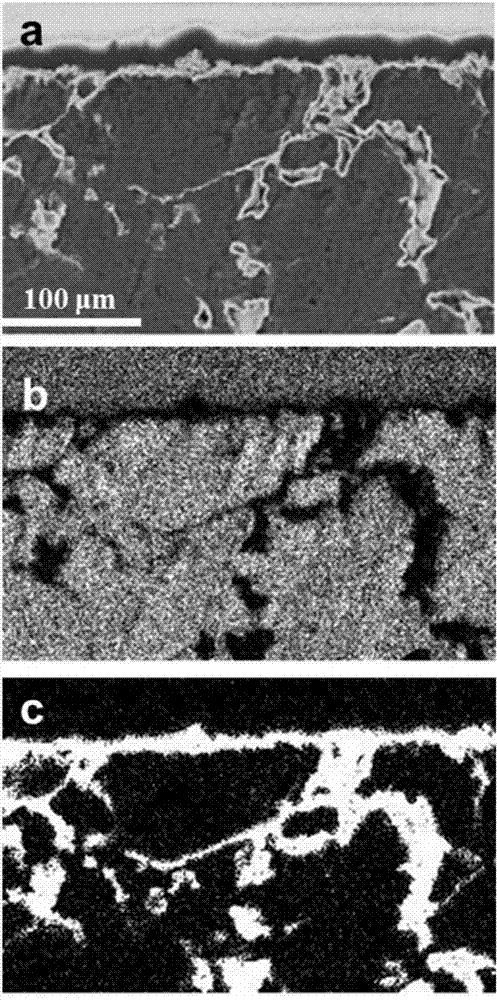

[0039] A kind of graphite preparation method covered with chromium carbide coating, it adopts attached figure 1 The experimental device shown is prepared, wherein, 1 is the inner crucible; 2 is the outer crucible; 3 is molten salt; 4 is carbon-based sample; 5 is metal; 6 is inert atmosphere or vacuum; 7 is sample fixing Corrosion-resistant alloy wire is used; 8 is the sample holder. Concrete preparation method comprises the following steps:

[0040] (1) Polish the graphite surface with sandpaper until the surface is smooth. The polished graphite was cleaned with absolute ethanol, and then kept at a constant temperature in a vacuum oven at 120°C for more than 12 hours.

[0041] (2) The surface of the metal chromium sample was polished with sandpaper to remove the surface oxide film, cleaned with absolute ethanol, and dried with a hair dryer.

[0042] (3) Put graphite and metal chromium in the inner crucible at the same time, add LiF-NaF-KF (molar ratio is 46.5:11.5:42) solid...

Embodiment 2

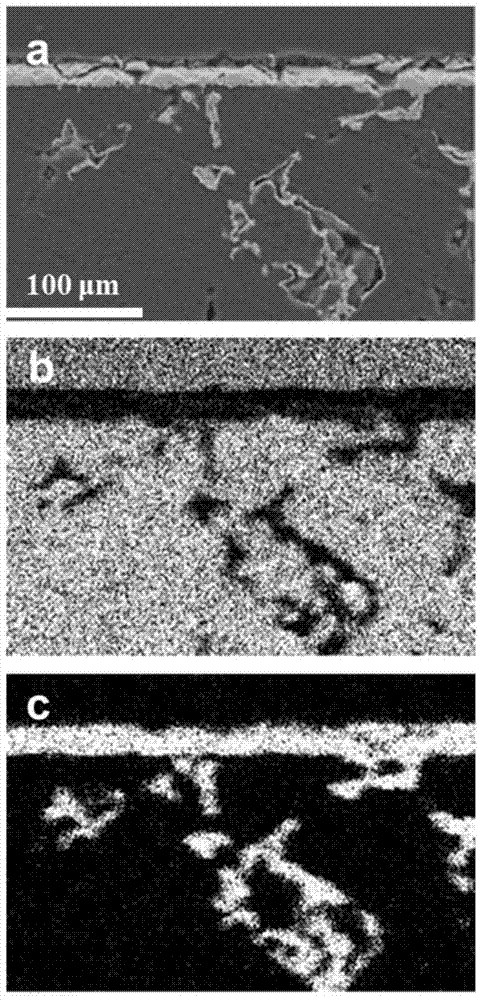

[0046] A method for preparing a carbon-carbon composite material covered with a chromium carbide coating, the experimental device used in the preparation is the same as that in Example 1. Concrete preparation method comprises the following steps:

[0047] (1) The carbon-carbon composite material is cleaned with absolute ethanol, and then kept at a constant temperature in a vacuum oven at 120° C. for more than 12 hours.

[0048] (2) Polish the surface of the metal chromium sample with sandpaper to remove the surface oxide film, clean it with absolute ethanol, and dry it with a hair dryer.

[0049] (3) The carbon-carbon composite material and metal chromium are placed in the inner crucible at the same time, and LiF-NaF-KF (molar ratio is 46.5:11.5:42) solid salt is added to the crucible, wherein the solid salt is added in an amount such that After the solid salt is molten, the carbon-carbon composite material and metal chromium can be completely submerged. The ratio of the surf...

Embodiment 3

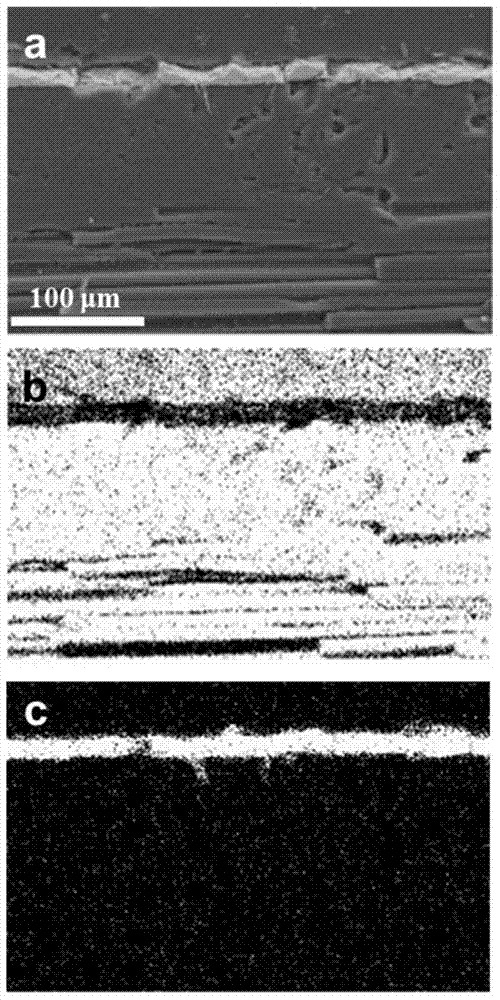

[0053] A kind of graphite preparation method that is covered with titanium carbide coating, the experimental device that its preparation adopts is the same as embodiment 1. Concrete preparation method comprises the following steps:

[0054] (1) Polish the graphite surface with sandpaper until the surface is smooth. The polished graphite was cleaned with absolute ethanol, and then kept at a constant temperature in a vacuum oven at 120°C for more than 12 hours.

[0055] (2) The surface of the metal titanium sample was polished with sandpaper to remove the surface oxide film, cleaned with absolute ethanol, and dried with a hair dryer.

[0056] (3) Put graphite and metal titanium in the inner crucible at the same time, add KCl-MgCl to the crucible 2

[0057] (The molar ratio is 68:32) solid salt, wherein, the amount of solid salt added so that graphite and metal titanium can be fully submerged after the solid salt is melted is as the criterion, and the ratio of the surface area...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com