Method for improving bonding strength of interface between hard coating and substrate

A technology of interfacial bonding strength and hard coating, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of coating and substrate performance deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

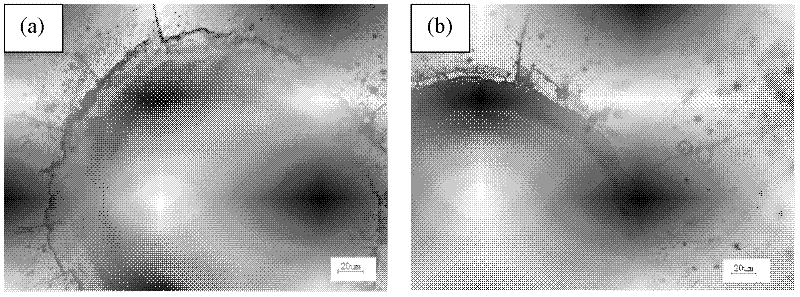

[0023] A 3 μm thick TiN coating was deposited on the YW2 cemented carbide substrate by arc ion coating technology. After 30 hours of ultra-low temperature treatment in liquid nitrogen at -196 ° C, a Rockwell indentation test was carried out on it. The indentation appearance is as follows figure 1 As shown: a) and b) are respectively the microscopic photos of the Rockwell indentation morphology before and after ultra-low temperature treatment. The level of adhesion of the layers is significantly improved. At the same time, the quantitative detection of the scratch test showed that the adhesion before treatment was 55N, and it rose to 83N after treatment, and the adhesion increased by 51%.

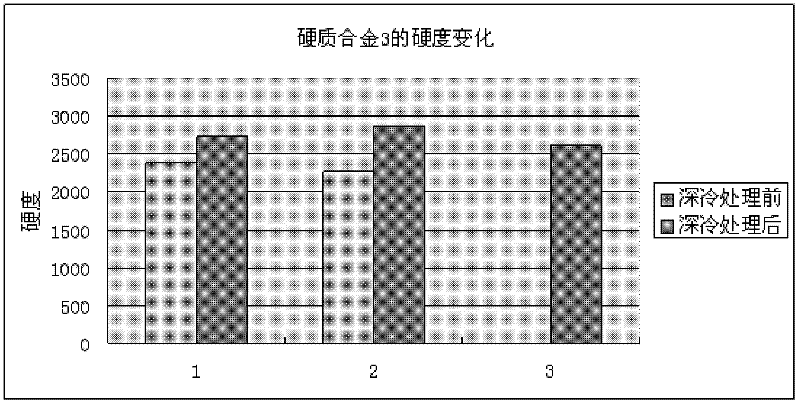

[0024] figure 2 It is the Vickers hardness of coated cemented carbide before and after ultra-low temperature treatment under the same conditions. Gray and red represent the hardness values before and after treatment respectively. improve. Since the test results of the microhardness tes...

Embodiment 2

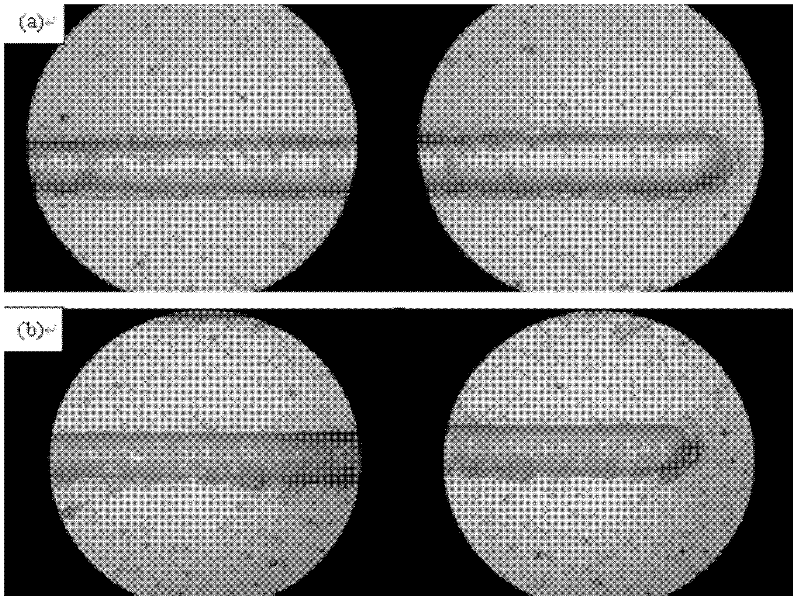

[0026] A 3 μm thick TiN coating was deposited on the polished 304 stainless steel substrate by arc ion plating technology. After 30 hours of ultra-low temperature treatment in liquid nitrogen at -196 ° C, a scratch test was carried out on it. The appearance of the scratch is as follows: image 3 Shown: a) and b) are the microscopic images of the scratch morphology before and after ultra-low temperature treatment, respectively. It can be seen that the TiN peeling off at the edge and central part of the scratch is serious before ultra-low temperature treatment, and the coating is lumpy after ultra-low temperature treatment. The shedding situation was obviously alleviated, and the coating on the edge and middle of the scratch did not completely fall off after the scratch was completed, and the coating that had not been treated basically fell off completely. This indicates that the interfacial bonding strength of TiN coating / stainless steel substrate has been significantly improved...

Embodiment 3

[0029] A 3μm-thick CrN coating was deposited on the YW2 cemented carbide substrate by arc ion coating technology. After 5 hours of ultra-low temperature treatment at -273°C in liquid helium, the scratch quantitative detection test was carried out. The test results show that after ultra-low temperature treatment The adhesion level of the CrN coating after treatment was significantly improved, the adhesion before treatment was 58N, and it rose to 72N after treatment, and the adhesion increased by 24%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com