Method for agglomerating and granulizing superfine nano WC-Co composite powder

A kind of composite powder and nanotechnology, applied in the field of cermet coating, can solve the problems of small particle size and quality, uniform transportation, poor fluidity, etc., achieve excellent comprehensive performance, prevent rapid coarsening, and good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

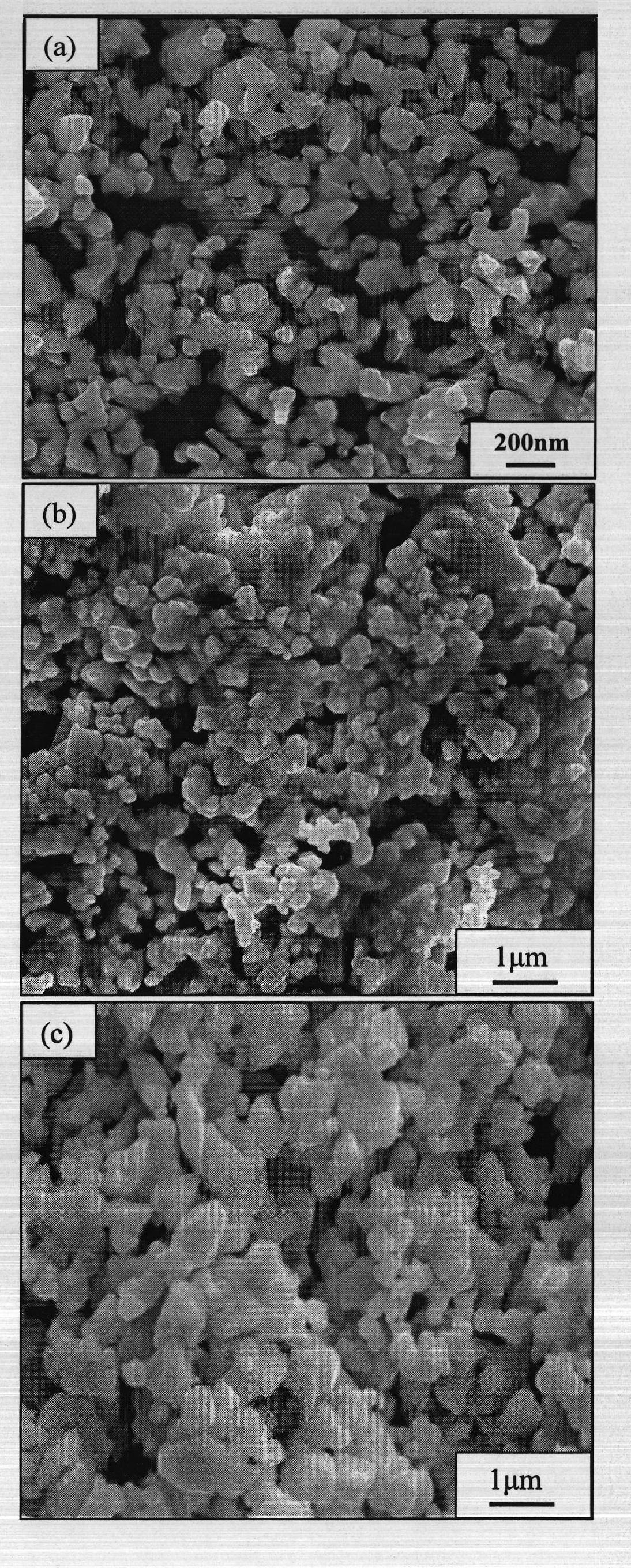

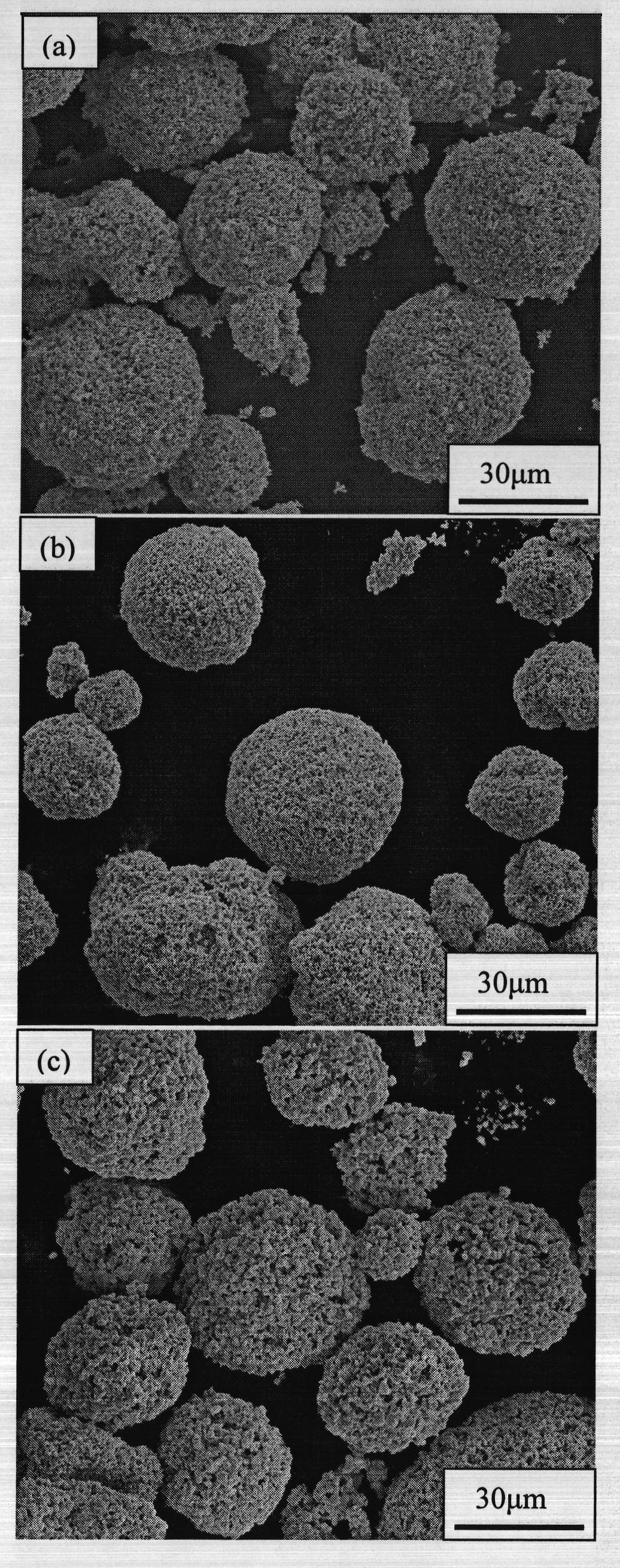

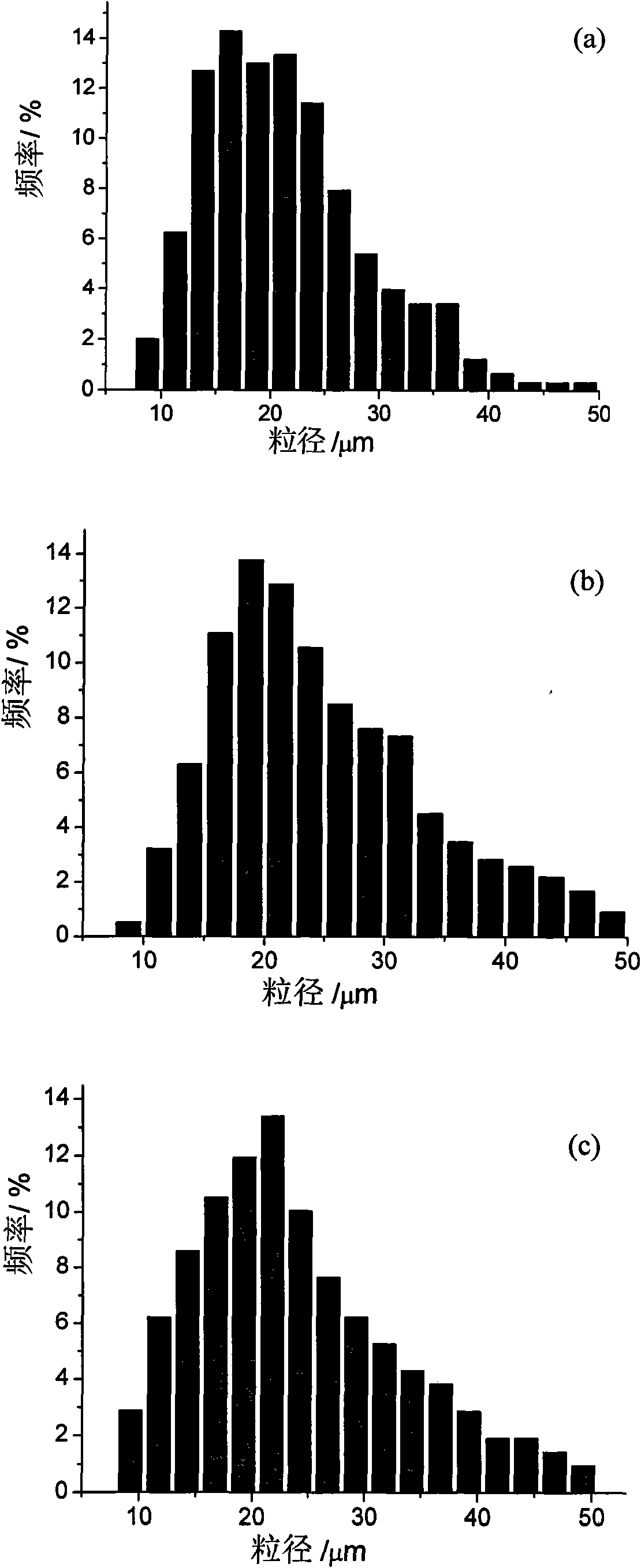

[0019] WC-12Co composite powder with an average particle size of 80nm (morphology such as figure 1 (a)) mixed with polyvinyl alcohol (PVA), polyethylene glycol (PEG) and deionized water in a certain proportion to prepare a slurry, wherein the WC-12Co composite powder quality is 45% of the total mass of the slurry, and the PVA quality is 2% of the composite powder mass, PEG mass is 3% of the composite powder mass. The specific steps are: first calculate the quality of deionized water required according to the predetermined slurry composition parameters, dissolve PVA and PEG in deionized water respectively, then mix and stir the composite powder and the aqueous solution of PVA, and finally add the aqueous solution of PEG, Stir for at least 30 minutes to obtain a slurry of WC-Co composite powder. If bubbles are generated, add n-butanol defoamer dropwise. After the slurry is prepared, the slurry is sprayed and granulated using centrifugal atomization drying equipment, the inlet ...

Embodiment 2

[0022] WC-12Co composite powder with an average particle size of 210nm (morphology such as figure 1 (b)) mixed with polyvinyl alcohol (PVA), polyethylene glycol (PEG) and deionized water in a certain proportion to prepare a slurry, wherein the WC-12Co composite powder quality is 55% of the total mass of the slurry, and the PVA quality is 3% of the composite powder mass, PEG mass is 2% of the composite powder mass. The specific steps are: first calculate the quality of deionized water required according to the predetermined slurry composition parameters, dissolve PVA and PEG in deionized water respectively, then mix and stir the composite powder and the aqueous solution of PVA, and finally add the aqueous solution of PEG, Stir for at least 30 minutes to obtain a slurry of WC-Co composite powder. If bubbles are generated, add n-butanol defoamer dropwise. After the slurry is prepared, use centrifugal atomization drying equipment to spray and granulate the slurry. The inlet temp...

Embodiment 3

[0025] WC-12Co composite powder with an average particle size of 380nm (morphology such as figure 1 (c)) mixed with polyvinyl alcohol (PVA), polyethylene glycol (PEG) and deionized water in a certain proportion to prepare a slurry, wherein the WC-12Co composite powder quality is 65% of the total mass of the slurry, and the PVA quality is 4% of the composite powder mass, PEG mass is 1% of the composite powder mass. The specific steps are: first calculate the quality of deionized water required according to the predetermined slurry composition parameters, dissolve PVA and PEG in deionized water respectively, then mix and stir the composite powder and the aqueous solution of PVA, and finally add the aqueous solution of PEG, Stir for at least 30 minutes to obtain a slurry of WC-Co composite powder. If bubbles are generated, add n-butanol defoamer dropwise. After the slurry is prepared, the slurry is sprayed and granulated using centrifugal atomization drying equipment. The inlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com