Preparation method and application of dual-purpose probe integrating solid-phase micro-extraction fibers and electrochemical detection working electrodes

A technology for extracting fibers and working electrodes, which is applied in the field of analytical chemistry, can solve problems affecting the sensitivity and accuracy of results of analytical methods, achieve good biocompatibility and environmental stability, good environmental stability, and reduce the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

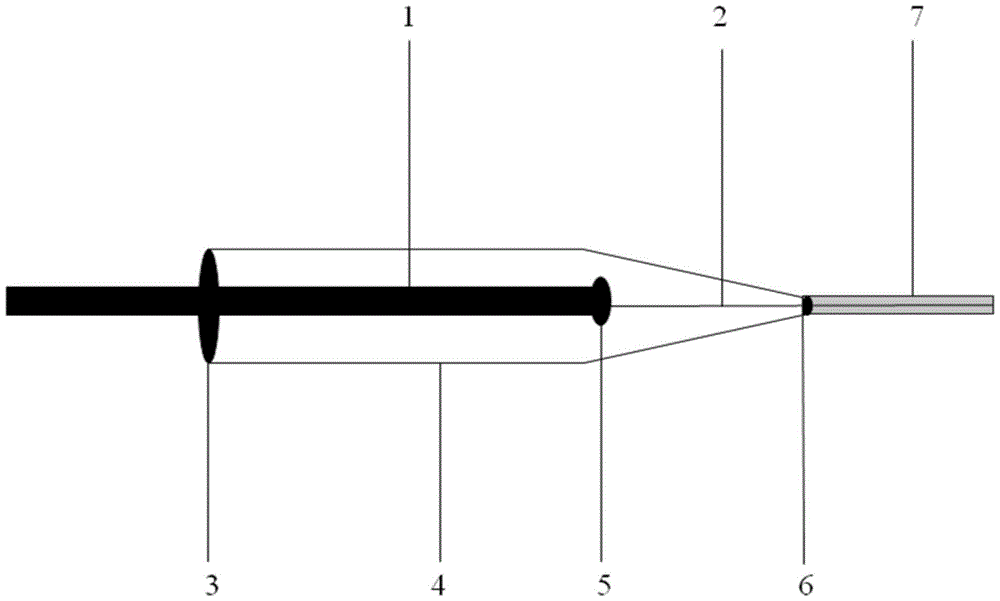

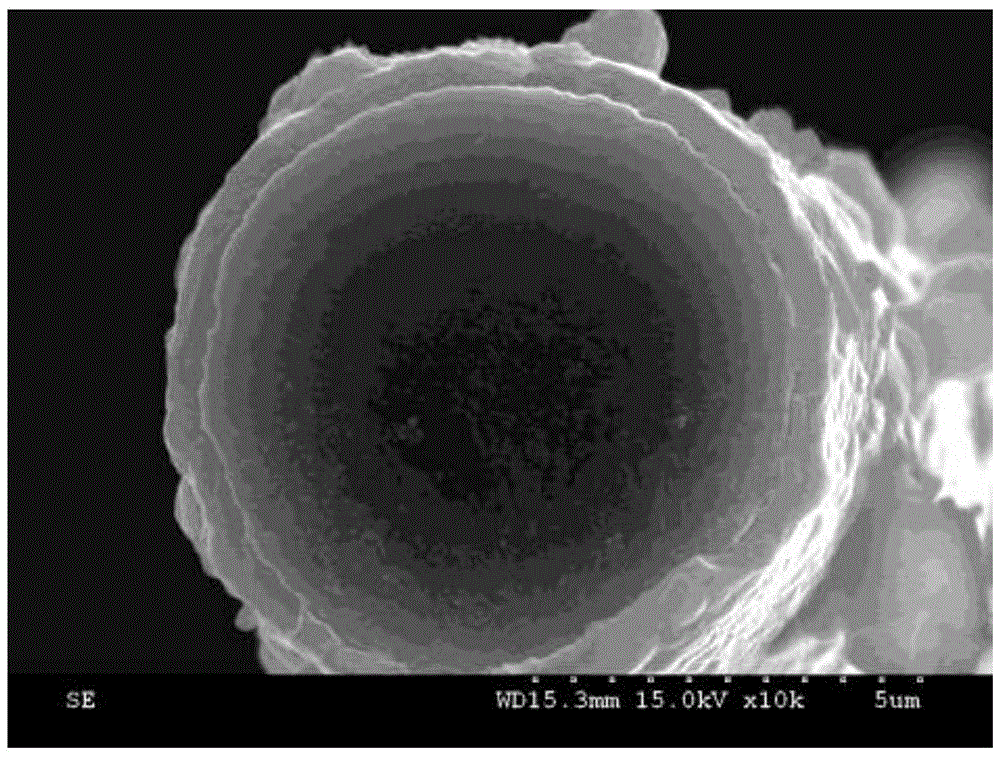

[0032] Dual-function probe integrating solid-phase microextraction fiber and electrochemical detection working electrode

[0033] (1) Take a carbon fiber (7μm in diameter) and use 30% HNO 3 solution, acetone, ethanol, double distilled water to ultrasonically clean the carbon fiber for 10 minutes, and dry at room temperature;

[0034] (2) Take a cleaned and dried carbon fiber and connect it with copper wire through silver conductive glue, and insert it into a glass capillary tube with a 10 μm tip drawn at one end;

[0035] (3) Use epoxy glue to seal and fix the carbon fiber and copper wire at both ends of the glass capillary, and fully dry at room temperature;

[0036] (4) Cut the carbon fiber at the tip of the capillary to obtain a length of about 1.0cm, and use it as a working electrode at 0.5mol / LH 2 SO 4 Cyclic scan activation in the solution in the range of -0.2 ~ 1.2V, to obtain a stable curve;

[0037] (5) After the activated electrode is cleaned and dried at room te...

Embodiment 2

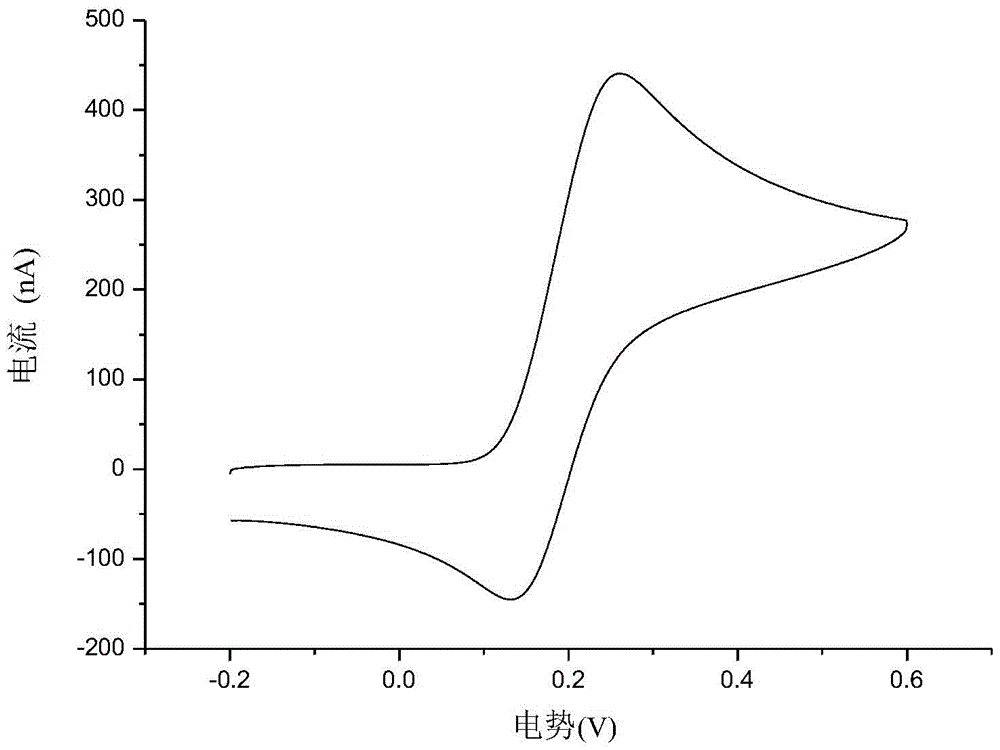

[0040] The dopamine in the aqueous solution was extracted by using the dual-functional probe integrating the solid-phase microextraction fiber and the electrochemical detection working electrode prepared in Example 1, and then used the probe as the working electrode for electrochemical detection.

[0041] Immerse the solid-phase microextraction-electrochemical detection working electrode dual-function probe into 5 mL of 20 μg / L dopamine solution (solvent is PBS, pH value is 7.40), and extract at room temperature for 20 min. After the extraction, rinse the surface quickly with distilled water, and The probe is used as the working electrode, the platinum wire is the counter electrode and the Ag / AgCl is the reference electrode. The three electrodes are immersed in the PBS buffer solution (pH value is 7.40), and connected to the CHI852D electrochemical work, at -0.2 The cyclic voltammetry test was carried out in the range of ~0.6V, and the scan rate was 0.05V / s.

[0042] image 3...

Embodiment 3

[0044] Utilize the dual-function probe that integrates solid-phase microextraction fiber and electrochemical detection working electrode prepared in Example 1 to extract the mixed solution of dopamine and 5-hydroxytryptamine in aqueous solution, and then use this probe as a working electrode for electrochemistry chemical detection.

[0045] Immerse the solid-phase microextraction-electrochemical detection dual-functional probe of the working electrode into 5mL of 20μg / L dopamine + 20μg / L 5-serotonin solution (the solvent is PBS, the pH value is 7.40), and extract at room temperature for 20min. After the extraction, use Rinse the surface quickly with distilled water, use the probe as the working electrode, platinum wire as the counter electrode and Ag / AgCl as the reference electrode, immerse the three electrodes in PBS buffer solution (pH value is 7.40), and work electrochemically with CHI852D Connected to each other, carry out cyclic voltammetry test in the range of -0.4 ~ 0.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com