Flexible packaging film capable of being composited by microwaves, automatic exhaust packaging film for microwave ovens, and packaging bag

A flexible packaging film, automatic exhaust technology, applied in the field of flexible packaging, can solve the problems of slow production speed, stable control of remaining materials, leakage, etc., and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

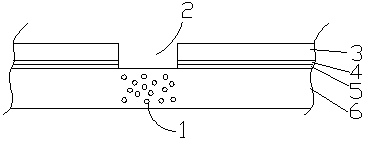

[0026] A microwaveable composite flexible packaging film is composed of multi-layer films, which are PET / INK / AD / PE from outside to inside. Such as figure 1 As shown, 3 is PET film, 4 is ink, 5 is glue, the innermost layer 6 is polyethylene film, and the innermost layer of polyethylene film is made of 50% low density polyethylene, 40% linear low density polyethylene, 9.9% metallocene polyethylene, 0.1% inorganic filler, the inorganic filler is titanium dioxide with a particle size of 30-700 nanometers.

[0027] The above-mentioned microwaveable composite flexible packaging film is treated with a carbon dioxide laser with a wavelength of 10250-10600 nanometers, and the surface material PET / INK / AD is burnt through to form a laser treatment area 2, and the innermost layer of polyethylene film is not easy to absorb the wavelength of this section Laser, so after laser treatment, there is no significant change in thickness, but a certain number of micropores1 are produced in the fil...

Embodiment 2

[0033]In this embodiment, the microwave-composite flexible packaging film is composed of multi-layer films, and the order from outside to inside is BOPP / INK / AD / CPP. The innermost CPP film is composed of 10% homopolypropylene, 89.8% copolymerized polypropylene, and 0.2% inorganic filler, which is calcium carbonate and silicon dioxide with a particle size of 30-700 nanometers. mixture.

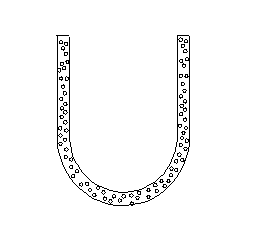

[0034] The above-mentioned microwaveable composite flexible packaging film is treated with a carbon dioxide laser with a wavelength of 10250-10600 nanometers, and the surface material BOPP / INK / AD is burned through to form a laser-treated area. After the innermost layer of CPP film is laser-treated, the thickness does not change significantly. , but a certain number of micropores are produced in the film, and the diameter of the micropores is 10-200 microns. The laser treatment area is made into a circle, and the diameter of the laser trace is 8 mm, so that it can be made into a microwave oven au...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com