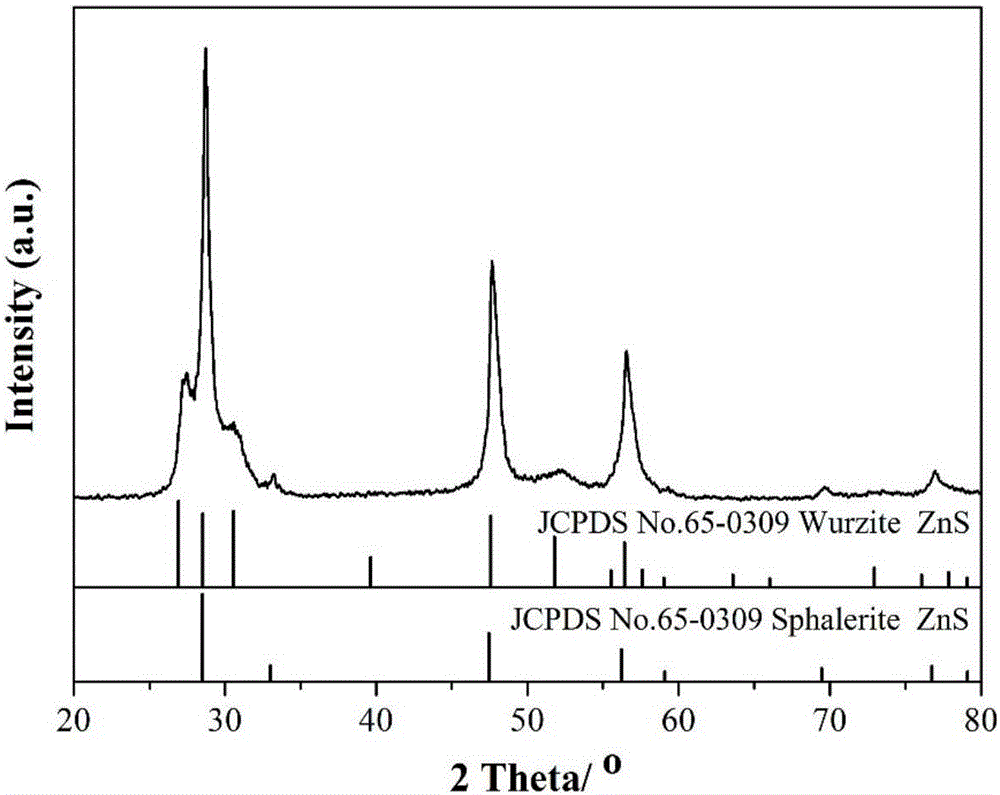

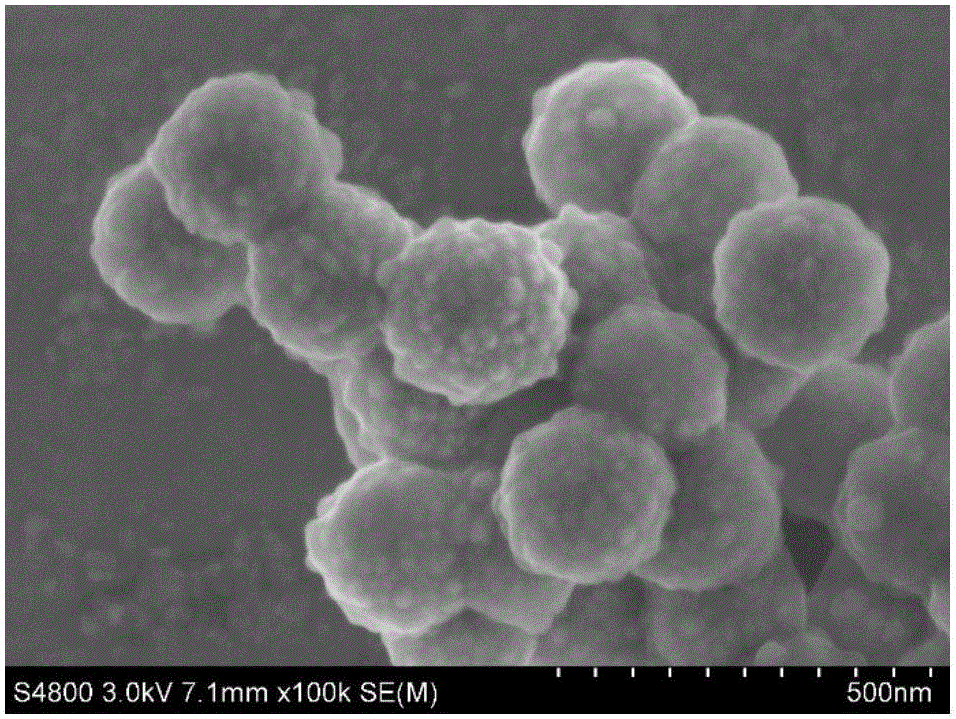

Method for preparing carbon-coated zinc sulfide microspheres through microwave hydrothermal method

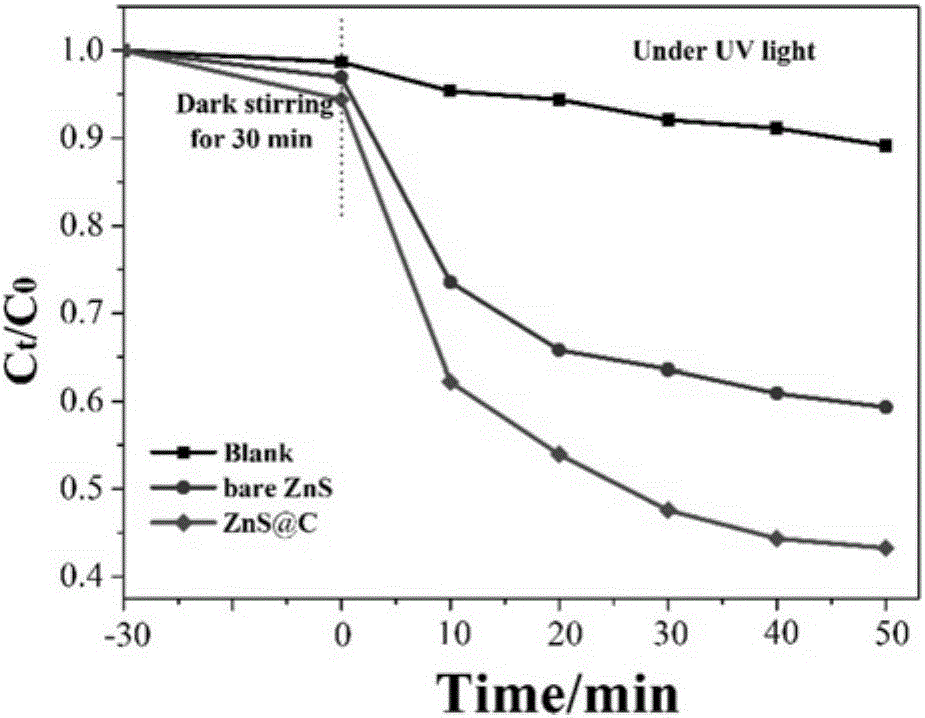

A technology of microwave hydrothermal method and carbon coating, which is applied in the field of nanomaterials, can solve problems such as restricting development, and achieve the effects of strong feasibility, strong crystallinity, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) 1mmol of analytically pure Zn(NO 3 ) 2 ·6H 2 The precursor solution that the thiourea of O and 40mmol is dissolved in deionized water makes;

[0028] 2) Add 2 g of glucose to the precursor solution under magnetic stirring conditions, and keep stirring for 1-2 hours;

[0029] 3) After fully stirring, put the reaction precursor solution in the polytetrafluoroethylene lining, the filling rate is 35%; after sealing the hydrothermal reaction kettle, put it into the microwave hydrothermal reaction apparatus, react at 180 ° C for 1 hour, and react Naturally cool to room temperature after finishing;

[0030] 4) The product was successively washed by centrifugation with deionized water and absolute ethanol, and the product was collected and vacuum-dried to obtain carbon-coated zinc sulfide microspheres.

Embodiment 2

[0032] 1) 1.6mmol of analytically pure Zn(NO 3 ) 2 ·6H 2 The precursor solution that the thiourea of O and 40mmol is dissolved in deionized water makes;

[0033] 2) Add 1 g of glucose to the precursor solution under magnetic stirring conditions, and keep stirring for 1-2 hours;

[0034] 3) After fully stirring, put the reaction precursor solution in the polytetrafluoroethylene lining, the filling rate is 35%; after sealing the hydrothermal reaction kettle, put it into the microwave hydrothermal reaction apparatus, and react at 180 ° C for 2 hours, and the reaction Naturally cool to room temperature after finishing;

[0035] 4) The product was successively washed by centrifugation with deionized water and absolute ethanol, and the product was collected and vacuum-dried to obtain carbon-coated zinc sulfide microspheres.

Embodiment 3

[0037] 1) 2mmol of analytically pure Zn(NO 3 ) 2 ·6H 2 The precursor solution that the thiourea of O and 20mmol is dissolved in deionized water makes;

[0038] 2) Add 0.1 g of glucose to the precursor solution under the condition of magnetic stirring, and keep stirring for 1-2 hours;

[0039] 3) After fully stirring, put the reaction precursor solution in the polytetrafluoroethylene lining, and the filling rate is 50%; after sealing the hydrothermal reaction kettle, put it into the microwave hydrothermal reaction apparatus, and react at 100°C for 2h, and react Naturally cool to room temperature after finishing;

[0040] 4) The product was successively washed by centrifugation with deionized water and absolute ethanol, and the product was collected and vacuum-dried to obtain carbon-coated zinc sulfide microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com