Surface treatment method of metal base materials

A metal substrate and surface treatment technology, applied in the direction of coating, electrolytic coating, electrophoretic plating, etc., can solve the problems of coating wear resistance and insufficient hardness, and achieve the effect of improving adhesion and enhancing surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

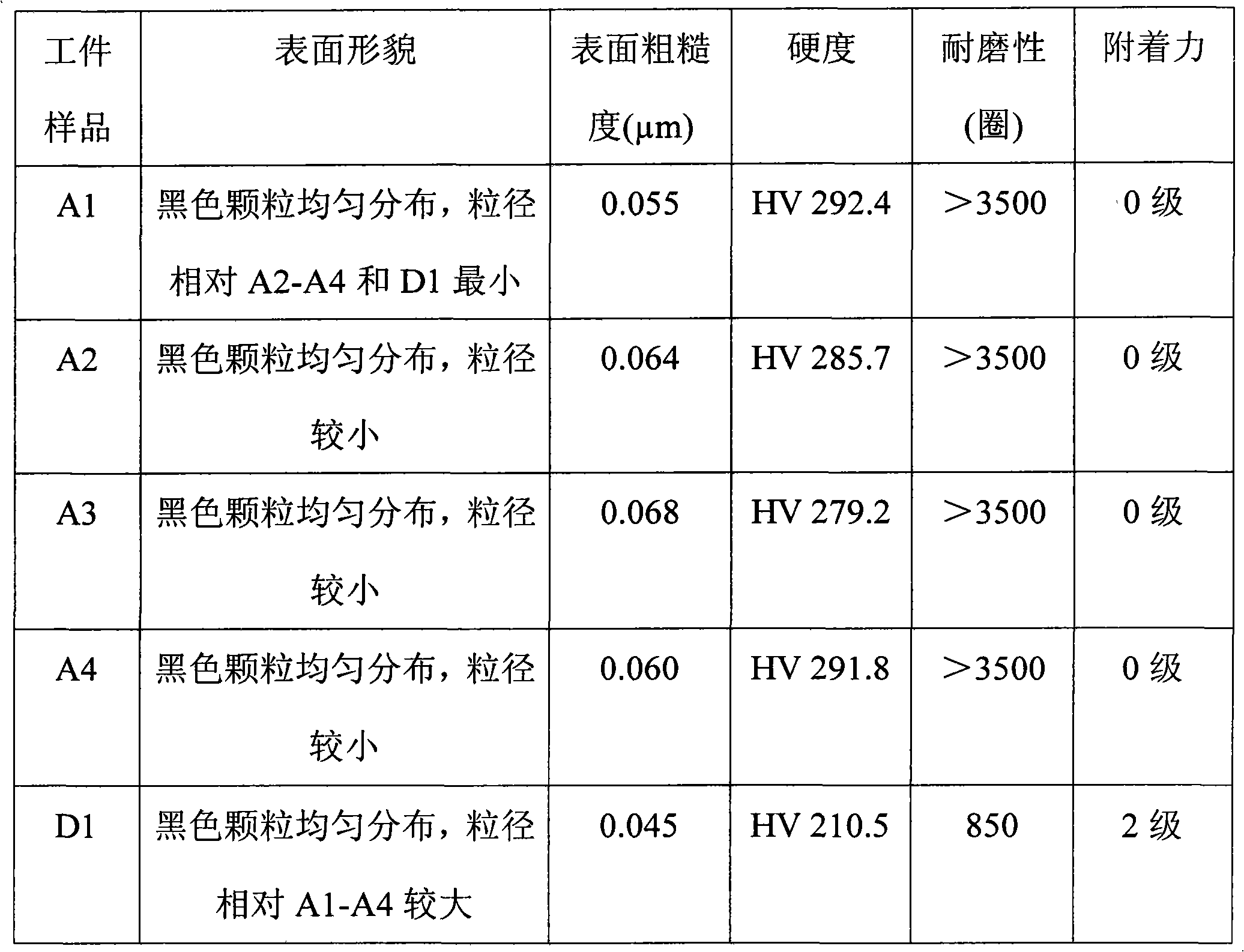

Examples

Embodiment 1

[0031] (1) Pretreatment: Soak the stainless steel workpiece (100mm×45mm×10mm) in the degreasing solution for 20 minutes, take it out, wash it with deionized water, and dry it.

[0032] (2) Preparation of electrophoretic paint: add 13.8g molybdenum disulfide (average particle size: 2.5μm), 4g graphite (average particle size: 2.5μm), 2g WS in 80mL deionized water 2 Additive (average particle size: 2.5 μm), then add 0.2 g of traradone, stir until uniform, drop ethanol to adjust the pH value to 6.0, and obtain the required electrophoretic paint.

[0033] (3) Electrophoretic coating: Pour the electrophoretic paint in step (2) into the electrolytic tank, use the workpiece in step (1) as the cathode, and the Au sheet as the anode. The temperature of the electrophoretic paint is 25°C and the voltage is 220V. , for cathodic electrophoretic coating, the electrophoresis time is 5min. Rinse with deionized water, and bake the workpiece in an oven at 175°C for 60min. The workpiece was tak...

Embodiment 2

[0036] Adopt the method identical with embodiment 1 to carry out surface treatment to workpiece, difference is: in step (4), laser modification condition is: laser power is 2.5KW, scanning speed is 1800mm / min, and laser spot size is 2mm× 2mm, N 2 The air flow rate is 15L / min; the laser modification time is 40s.

[0037] Through the above steps, the workpiece of this embodiment is obtained, denoted as A2.

Embodiment 3

[0039] Adopt the method identical with embodiment 1 to carry out surface treatment to workpiece, difference is:

[0040] In step (2), add 9g molybdenum disulfide (average particle size is 2.5 μm), 2.5g graphite (average particle size is 2.5 μm), 1.3g WS in 80mL deionized water 2 Additives (average particle size is 2.5 μm), then add 0.2g traradone, electromagnetically stir until uniform, dropwise add dimethylethanolamine to adjust the pH value to 8.0, to obtain the electrophoretic paint of this embodiment;

[0041] In step (3), the workpiece is used as the anode, and the tinplate is used as the cathode. The electrophoretic paint of this embodiment is poured into the electrolytic tank, and anodic electrophoretic coating is performed on the surface of the workpiece. The electrophoresis time is 2 minutes.

[0042] Then carry out laser modification to the workpiece according to step (4) of Example 1.

[0043] Through the above steps, the workpiece of this embodiment is obtained, d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com