Method for wrapping gold-silver alloy nanometer particles through silicon dioxide

A gold-silver alloy and nanoparticle technology, which is applied in the field of silica-coated gold-silver alloy nanoparticles, can solve the problems of increased process difficulty and process, long reaction time, and complexity, and achieves short reaction time, simple method, The effect of shape rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

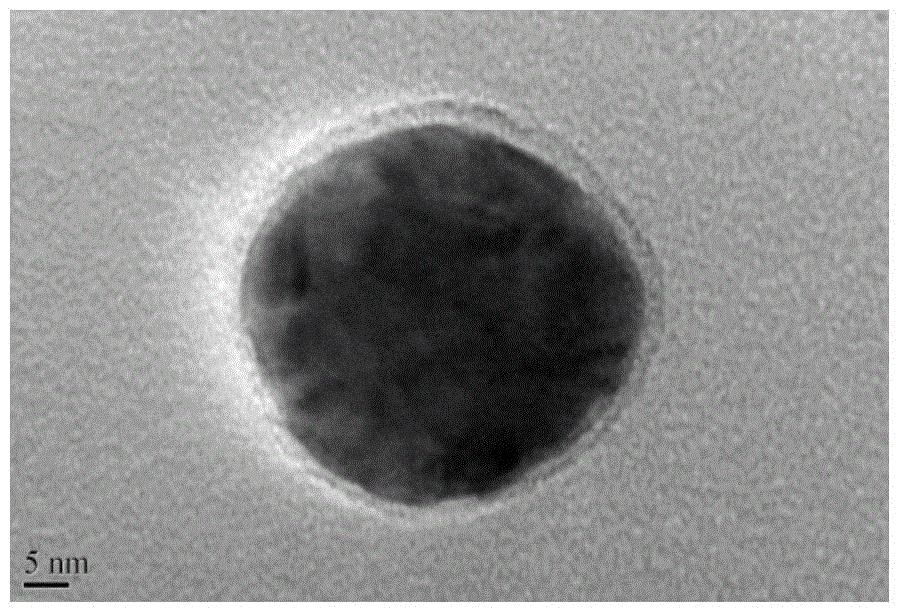

[0023] Add 1mL of 0.01mol / L silver nitrate aqueous solution and 1mL of 0.01mol / L chloroauric acid aqueous solution into 80mL of boiling distilled water, mix well, then add 8mL of 0.01mol / L sodium citrate aqueous solution, boil for 20 minutes, Centrifuge and wash twice with distilled water, and pour off the supernatant to obtain gold-silver alloy nanoparticles. Add the obtained gold-silver alloy nanoparticles into 45mL of isopropanol, place it in a water bath at 40°C, stir and mix evenly, then add 15mL of deionized water, 1.0mL of ammonia water, 4μL of tetraethyl orthosilicate, 40 ℃ and stirred for 3 hours. After the reaction was completed, it was naturally cooled to room temperature, and washed three times with distilled water and ethanol alternately to obtain SiO 2 Au-Ag alloy@SiO with a shell thickness of 2nm 2 Composite nanoparticles (see figure 1 ).

Embodiment 2

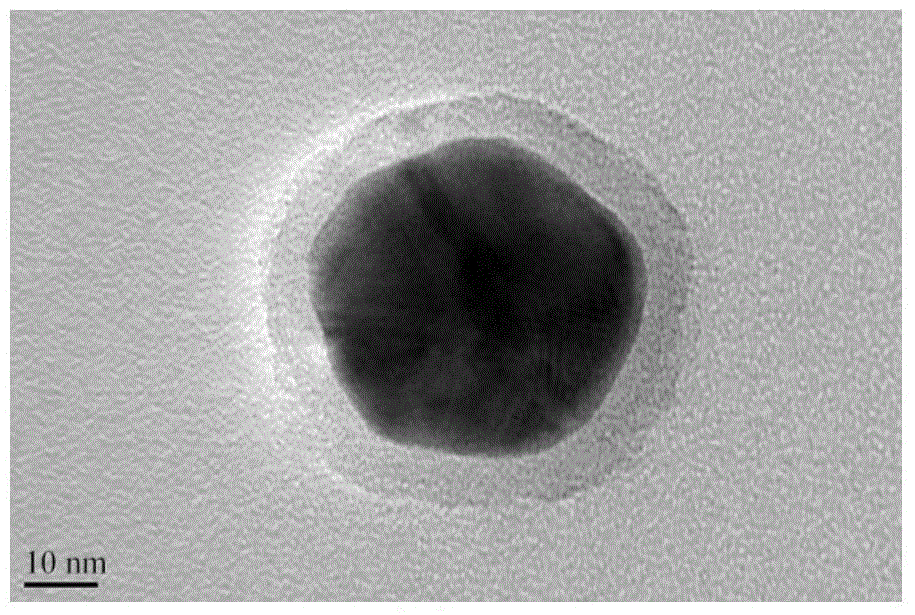

[0025] The preparation method of gold-silver alloy nanoparticles in this example is the same as that in Example 1. Add the obtained gold-silver alloy nanoparticles into 45mL of isopropanol, place it in a water bath at 40°C, stir and mix evenly, then add 15mL of deionized water, 1.5mL of ammonia water, 6 μL of tetraethyl orthosilicate, 40 ℃ and stirred for 3 hours. After the reaction was completed, it was naturally cooled to room temperature, and washed three times with distilled water and ethanol alternately to obtain SiO 2 Au-Ag alloy@SiO with a shell thickness of 5nm 2 Composite nanoparticles (see figure 2 ).

Embodiment 3

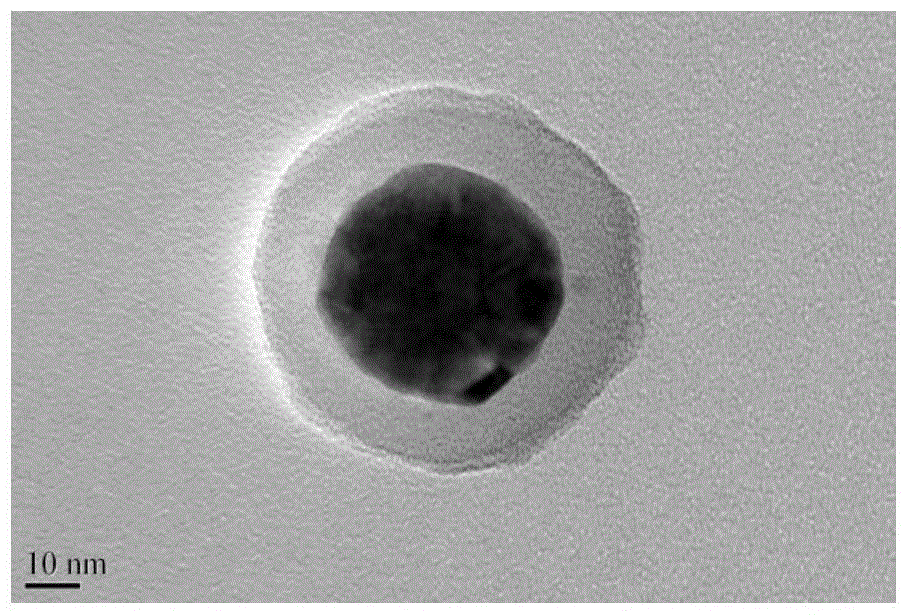

[0027] The preparation method of gold-silver alloy nanoparticles in this example is the same as that in Example 1. Add the obtained gold-silver alloy nanoparticles into 45mL of isopropanol, place it in a 40°C water bath, stir and mix evenly, then add 15mL of deionized water, 1.5mL of ammonia water, 9 μL of tetraethyl orthosilicate, 40 ℃ and stirred for 3 hours. After the reaction was completed, it was naturally cooled to room temperature, and washed three times with distilled water and ethanol alternately to obtain SiO 2 Au-Ag alloy@SiO with a shell thickness of 10nm 2 Composite nanoparticles (see image 3 ). From Figure 4 It can be seen from the figure that the Au-Ag alloy nanoparticles are well dispersed, the silica coating is uniform, and the Au-Ag alloy@SiO 2 The core-shell structure is monodisperse composite nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com