Synthesis method of silicon dioxide coated lithium-rich manganese-based cathode material

A lithium-rich manganese-based, positive electrode material technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problem of reducing the safety performance of lithium-ion batteries, accelerating electrode-electrolyte side reactions, and decreasing battery cycle stability and other issues, to achieve the effects of environmental recyclability, improved electrochemical performance, and dense coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

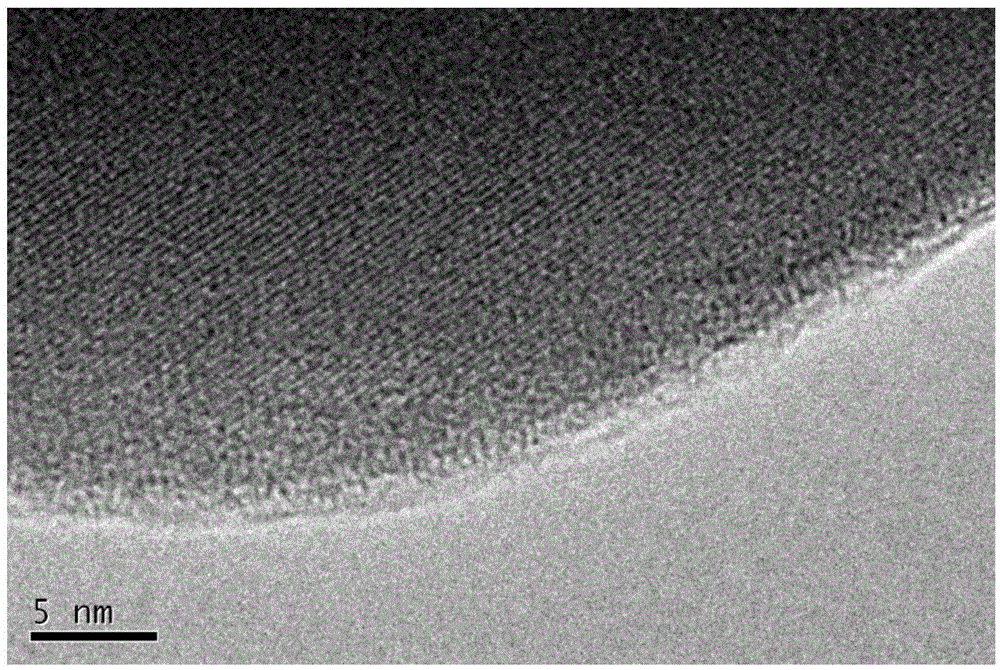

[0033] Weigh Li 1.2 Ni 0.2 mn 0.6 o 2 (0.6Li[Li 1 / 3 mn 2 / 3 ]O 2 0.4Li[Ni 1 / 2 mn 1 / 2 ]O 2 ) 5g of lithium-rich manganese-based positive electrode material powder was added to a beaker containing 100mL of dispersion liquid (ethanol / deionized water=3 / 1, volume ratio), stirred and dispersed in a water bath at room temperature for 0.5h to form a suspension. Use a microsampler to take 200 μL of tetraethyl orthosilicate (according to SiO 2 In terms of the coating, the coating amount is 1 wt% of the lithium-rich manganese-based positive electrode material) into 10 ml of ethanol, and stirred to obtain a uniformly dispersed tetraethyl orthosilicate dispersion. In the case of continuous stirring to disperse the suspension, the tetraethyl orthosilicate dispersion was slowly added dropwise to the Li 1.2 Ni 0.2 mn 0.6 o 2 In the suspension, set the temperature of the water bath to 40°C. While evaporating the solvent of the dispersion, tetraethyl orthosilicate is hydrolyzed on t...

Embodiment 2

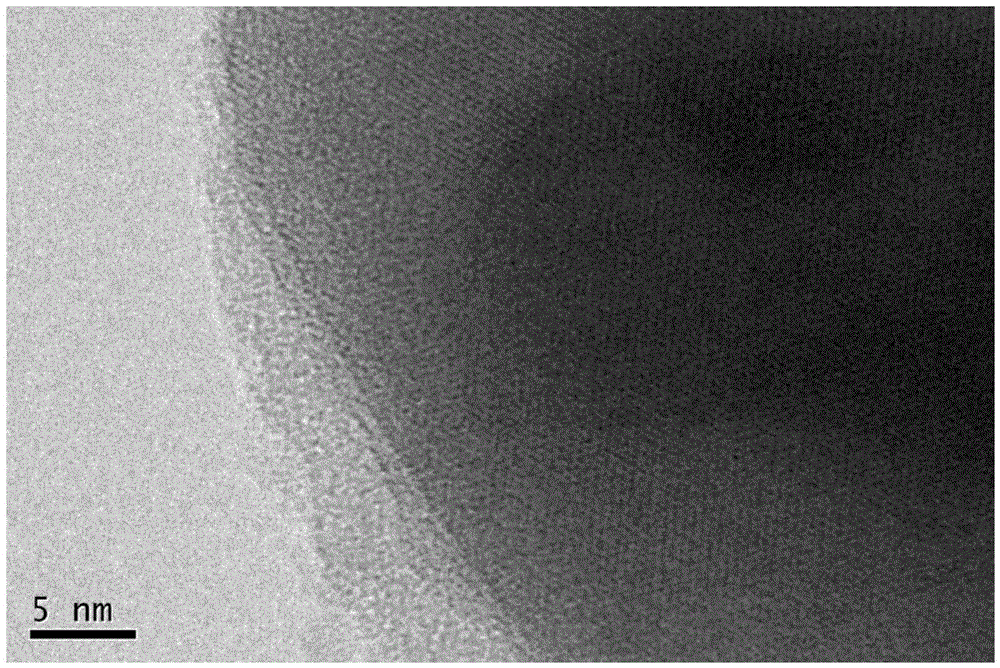

[0036] Weigh Li 1.2 Ni 0.2 mn 0.6 o 2 (0.6Li[Li 1 / 3 mn 2 / 3 ]O 2 0.4Li[Ni 1 / 2 mn 1 / 2 ]O 2 ) 5g of lithium-rich manganese-based positive electrode material powder was added to a beaker containing 100mL of dispersion liquid (ethanol / deionized water=3 / 1, volume ratio), stirred and dispersed in a water bath at room temperature for 0.5h to form a suspension. Use a microsampler to take 400 μL of tetraethyl orthosilicate (according to SiO 2 In terms of the coating, the coating amount is 2 wt% of the lithium-rich manganese-based positive electrode material) into 10 ml of ethanol, and stirred to obtain a uniformly dispersed tetraethyl orthosilicate dispersion. In the case of continuous stirring to disperse the suspension, the tetraethyl orthosilicate dispersion was slowly added dropwise to the Li 1.2 Ni 0.2 mn 0.6 o 2 In the suspension, set the temperature of the water bath to 40°C. While evaporating the solvent of the dispersion, tetraethyl orthosilicate is hydrolyzed on t...

Embodiment 3

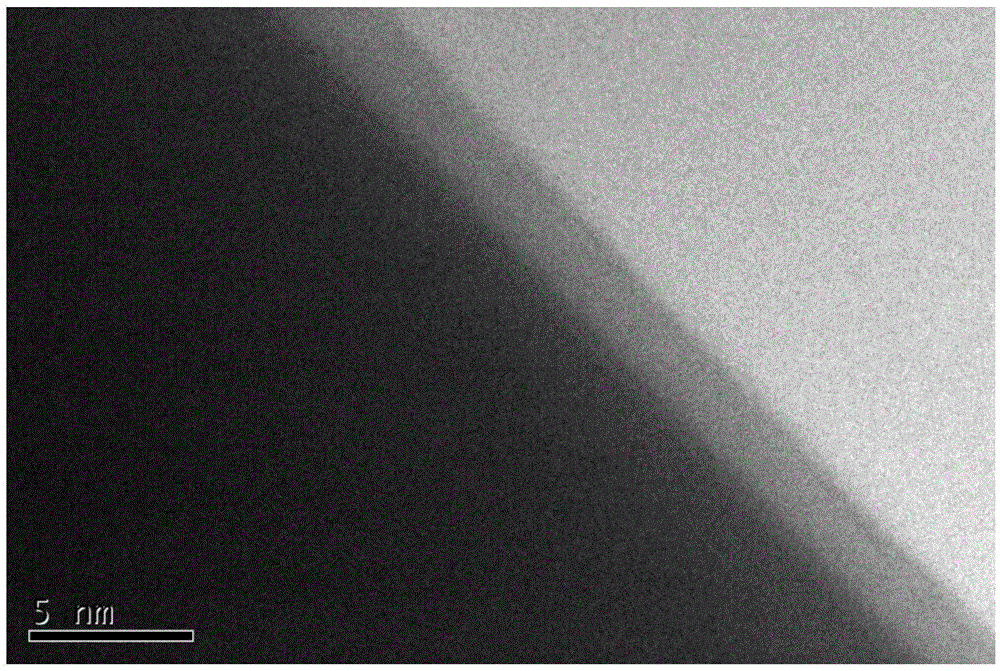

[0039] Weigh Li 1.2 Ni 0.2 mn 0.6 o 2 (0.6Li[Li 1 / 3 mn 2 / 3 ]O 2 0.4Li[Ni 1 / 2 mn 1 / 2 ]O 2 ) 5g of lithium-rich manganese-based positive electrode material powder was added to a beaker containing 100mL of dispersion liquid (ethanol / deionized water=1 / 1, volume ratio), stirred and dispersed in a water bath at room temperature for 0.5h to form a suspension. Use a microsampler to take 400 μL of tetraethyl orthosilicate (according to SiO 2 In terms of the coating, the coating amount is 2 wt% of the lithium-rich manganese-based positive electrode material) into 10 ml of ethanol, and stirred to obtain a uniformly dispersed tetraethyl orthosilicate dispersion. In the case of continuous stirring to disperse the suspension, the tetraethyl orthosilicate dispersion was slowly added dropwise to the Li 1.2 Ni 0.2 mn 0.6 o 2 In the suspension, set the temperature of the water bath to 40°C. While evaporating the solvent of the dispersion, tetraethyl orthosilicate is hydrolyzed on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com