Liquid-state lead bismuth alloy corrosion resisting coating layer and preparation method thereof

A technology of liquid lead-bismuth alloy and corrosion coating, which is applied in metal material coating process, coating, fusion spraying, etc., can solve the problems of high cost and complicated process, and achieve low cost, high efficiency and small speed gradient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

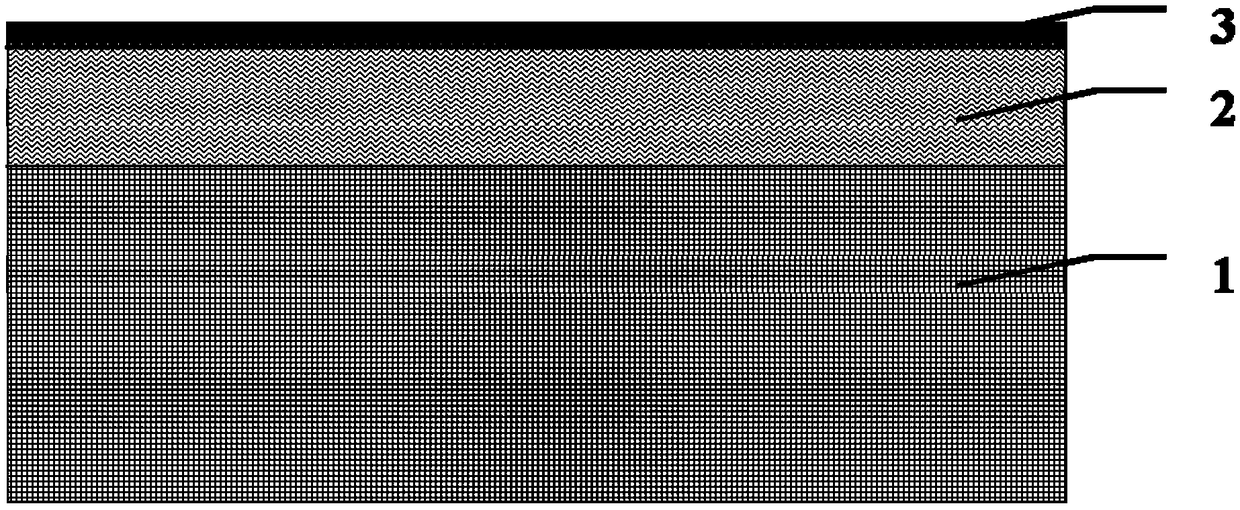

[0023] The embodiment of the present invention provides a method for preparing the above liquid lead-bismuth alloy corrosion-resistant coating, including:

[0024] Select the substrate, degrease and degrease the substrate, and then pre-treat the position to be sprayed. The pretreatment in the embodiment of the present invention includes sand blasting treatment, transferred arc cleaning and preheating treatment.

[0025] Sand blasting can remove the adsorbate and oxide layer on the surface of the substrate to increase surface activity and improve the bonding strength between the coating and the substrate. In order to reduce the erosion of the surface of the prepared coating when the liquid LBE flows during service, the prepared coating should have a lower roughness to ensure the good fluidity of the liquid LBE. Therefore, compared with the conventional sandblasting treatment, this In the invention, the sandblasting pressure is lower and the sand grain size is finer. During th...

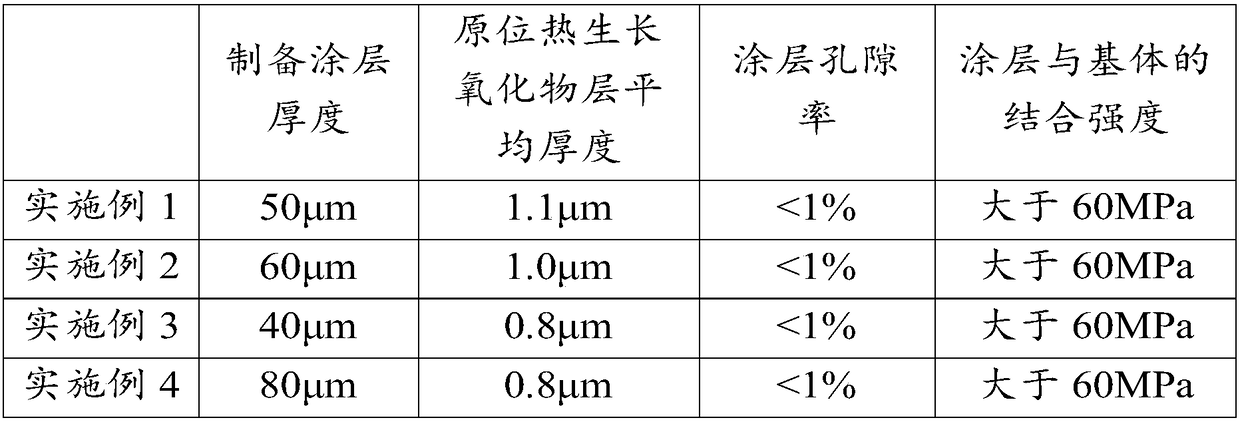

Embodiment 1

[0036] This embodiment provides a liquid lead-bismuth alloy corrosion-resistant coating, which is mainly made through the following steps:

[0037] Degrease and degrease the SIMP martensitic heat-resistant steel substrate, use white corundum sandblasting to roughen the sprayed surface, the sand particle size is 60#, the sandblasting pressure is 0.15MPa, and the sandblasting distance is 200mm. Grit or dust.

[0038] Put the sandblasting roughened substrate into the sample holder and place it in a low-pressure plasma spraying vacuum chamber, evacuate to 0.5mbar, then backfill with argon gas to 35mbar, and perform transfer arc cleaning on the substrate, the current of the plasma spray gun is 900A, transfer The arc current is 25A, the argon gas is 90L / min, the hydrogen gas is 4L / min, the spray distance is 350mm, and the spray gun moving speed is 150mm / s.

[0039] The preheating treatment is carried out without powder feeding, the vacuum chamber pressure is 35mbar, the plasma spra...

Embodiment 2

[0044] This embodiment provides a liquid lead-bismuth alloy corrosion-resistant coating, which is mainly made through the following steps:

[0045] Degrease and degrease the T91 martensitic heat-resistant steel substrate, use zirconium corundum to roughen the sprayed surface, the sand particle size is 80#, the sandblasting pressure is 0.18MPa, and the sandblasting distance is 220mm. Grit or dust.

[0046] Put the sandblasting roughened substrate into the sample holder and place it in a low-pressure plasma spraying vacuum chamber, evacuate to 0.5mbar, then backfill with argon gas to 40mbar, and perform transfer arc cleaning on the substrate, the current of the plasma spray gun is 1000A, transfer The arc current is 28A, the argon gas is 100l / min, the hydrogen gas is 3l / min, the spray distance is 450mm, and the spray gun moving speed is 200mm / s.

[0047] The preheating treatment is carried out without powder feeding, the vacuum chamber pressure is 40mbar, the plasma spray gun cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com