Technique for enhancing amorphous forming ability of alloy melt

A process method and alloy technology, applied in the field of solid-state amorphous alloy preparation process, can solve the problems of increasing the difficulty of rapid solidification process, lack of effective technical methods, etc., and achieve the improvement of quality and macroscopic physical properties, high technical reliability, and easy implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

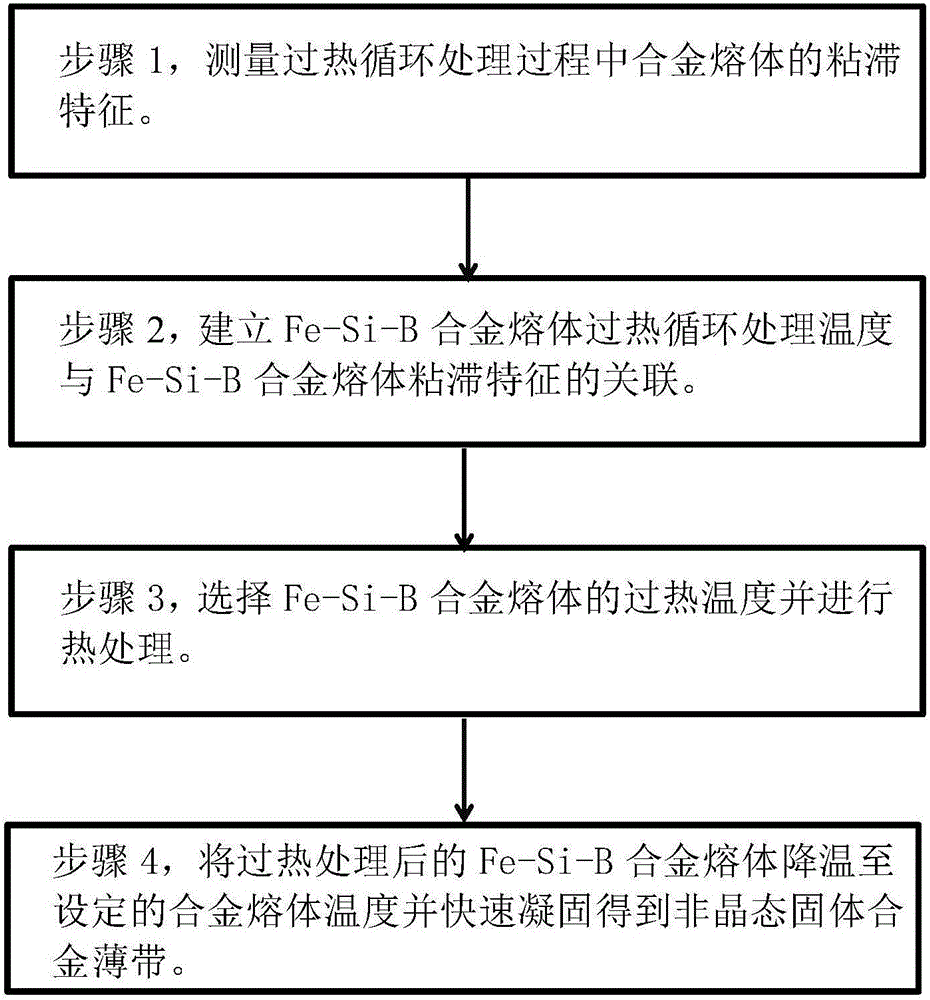

[0033] Embodiment 1: Taking the preparation of Fe-Si-B amorphous solid alloy thin strip as an example, the amorphous solid alloy thin strip is prepared by the high-speed planar flow continuous casting method commonly used in this field. The specific operation steps of a process method for improving the amorphous forming ability of alloy melt proposed by the present invention are as follows:

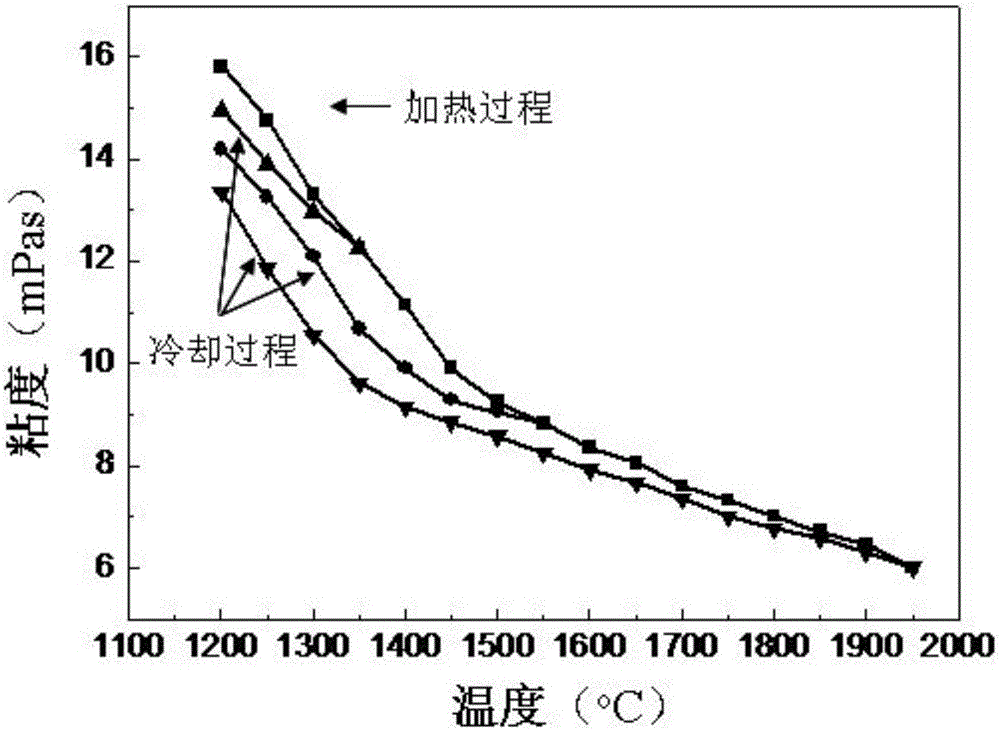

[0034] Step 1: (1) Select the superheating temperature of the Fe-Si-B alloy melt to be 1950°C, and the temperature range of thermal cycle treatment is 1200-1950°C; (2) Use a high-temperature viscosity measuring instrument (product of GBX company, model: Viscodrop 2000) to measure the melt viscosity, the heating and cooling speed of the Fe-Si-B alloy melt is 10°C / min, in order to ensure the accuracy of the viscosity measurement, keep warm for 1 hour at each measurement temperature, and then measure. The resulting viscosity change with temperature is characterized by figure 2 As shown, it...

Embodiment 2

[0039] Embodiment 2: Taking the preparation of Fe-Si-B amorphous solid alloy thin strip as an example, the amorphous solid alloy thin strip is prepared by the high-speed planar flow continuous casting method commonly used in this field. The specific operation steps of a process method for improving the amorphous forming ability of alloy melt proposed by the present invention are as follows:

[0040] Step 1: (1) Select the superheating temperature of the Fe-Si-B alloy melt to be 1550°C, and the temperature range of thermal cycle treatment to be 1200-1550°C; (2) Use a high-temperature viscosity measuring instrument to measure the melt viscosity, Fe-Si The heating and cooling speeds of the -B alloy melt are both 10°C / min. In order to ensure the accuracy of the viscosity measurement, the temperature is kept at each measurement temperature for 1 hour before measurement. The resulting viscosity change with temperature is characterized by figure 2 As shown, it shows the viscous phe...

Embodiment 3

[0045] Embodiment 3: Taking the preparation of Fe-Si-B amorphous solid alloy thin strip as an example, the amorphous solid alloy thin strip is prepared by the high-speed planar flow continuous casting method commonly used in this field. The specific operation steps of a process method for improving the amorphous forming ability of alloy melt proposed by the present invention are as follows:

[0046] Step 1: (1) Select the superheating temperature of the Fe-Si-B alloy melt to be 1350°C, and the temperature range of thermal cycle treatment to be 1200-1350°C; (2) Use a high-temperature viscosity measuring instrument to measure the melt viscosity, the melt The heating and cooling speeds are both 10°C / min. In order to ensure the accuracy of the viscosity measurement, the temperature is kept at each measurement temperature for 1 hour before the measurement. The resulting viscosity change with temperature is characterized by figure 2 As shown, it shows the viscous phenomenon after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com