High-iron content Fe-Si-B-P-Cu-Nb amorphous and nanocrystalline soft magnetic alloy and preparation method

A fe-si-b-p-cu-nb, amorphous nanocrystalline technology, applied in the field of Fe-Si-B-P-Cu-Nb series amorphous nanocrystalline alloys, can solve the problems of low saturation magnetization and limited application, etc. Achieving the effect of high saturation magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

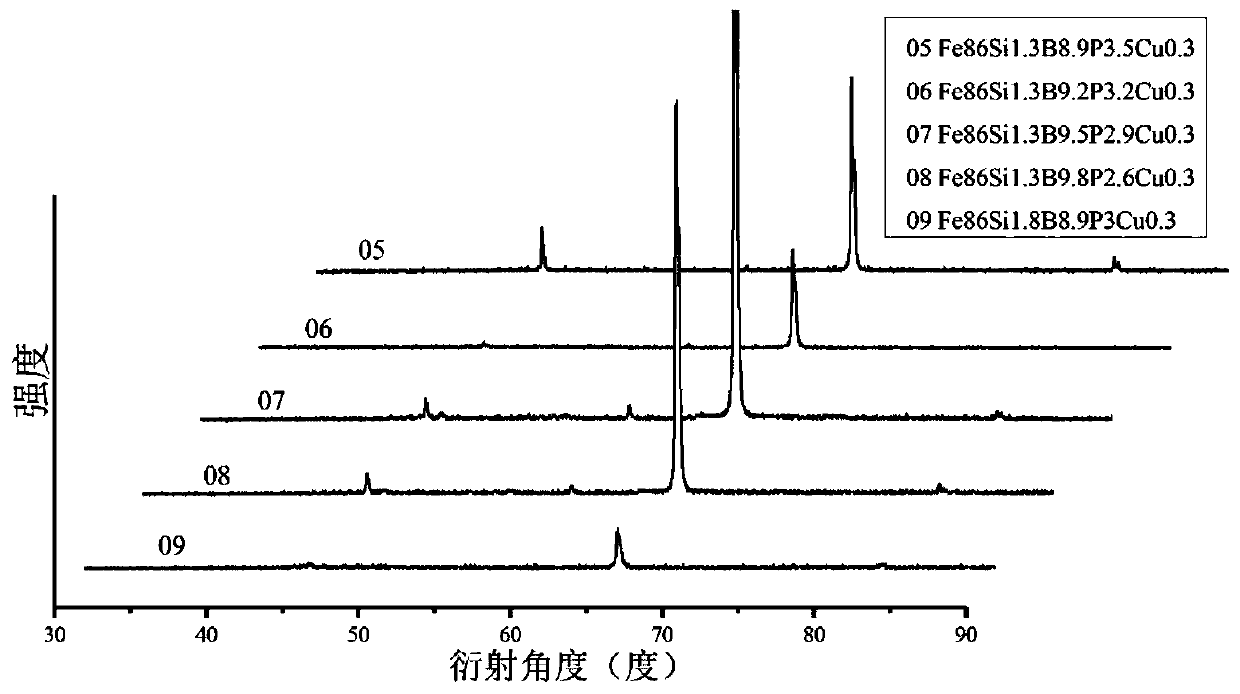

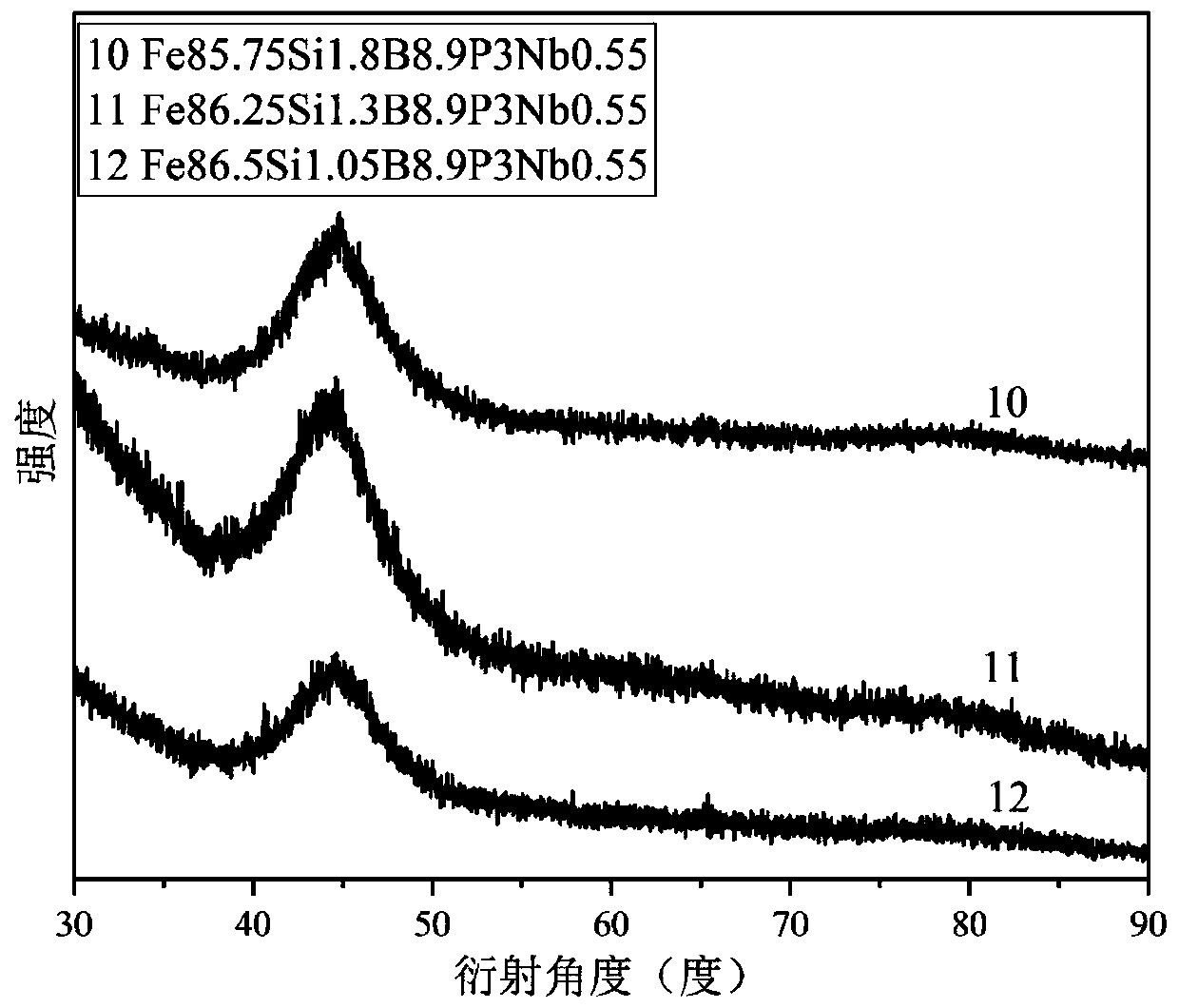

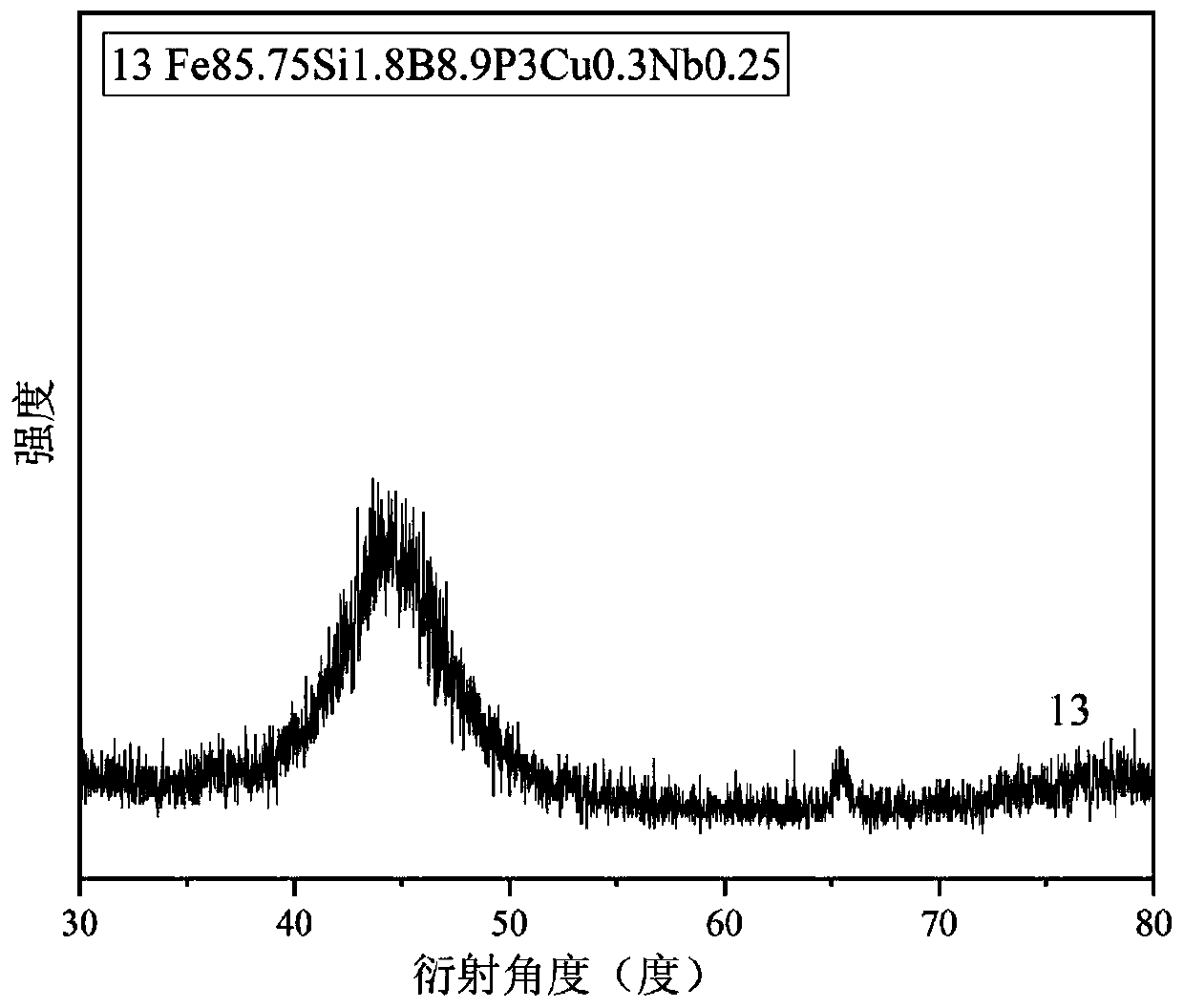

[0030] Table 1 shows some examples of the alloys of the present invention. The preparation, characterization and properties of the alloys in the examples in Table 1 are described in detail below.

[0031] (1) Batching: 14 kinds of alloys in table 1 all adopt the industrial FeB alloy (the impurity content is lower than 0.8wt%), P The industrial FeP alloy with a content of 27.1wt% (the impurity content is less than 1.6wt%), the Cu with a purity of 99.5wt%, and the Nb with a purity of 99.7wt%, are dosed according to the above atomic percentage content using a high-precision electronic analytical balance.

[0032] (2) Master alloy smelting: Put the prepared raw materials into the copper crucible of the non-consumable vacuum electric arc furnace, place the FeB alloy and FeP alloy that are easy to splash or volatilize at the bottom of the copper crucible, and then place the bulk Fe bedding on top of it. Close the furnace door and evacuate to 5×10 with mechanical pump and molecular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com