Nanometer TiF3 catalyzed high-volume hydrogen-storing alloy and preparation method thereof

A hydrogen storage alloy, high-capacity technology, applied in the field of hydrogen storage alloy materials, can solve the problem of extremely poor hydrogen absorption and desorption kinetics of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

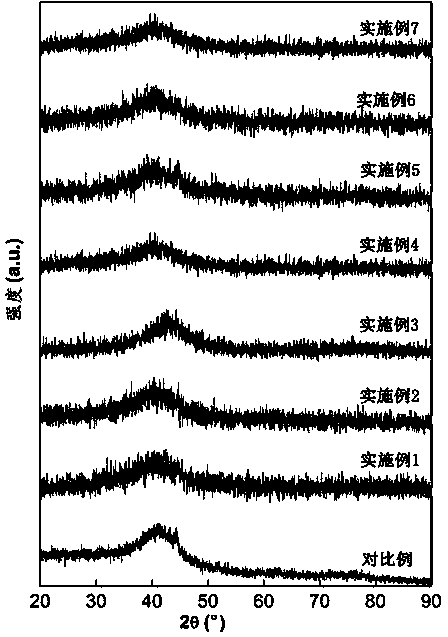

Image

Examples

preparation example Construction

[0031] The preparation method of the high-capacity hydrogen storage alloy for the fuel cell of the present invention comprises the following steps:

[0032] 1. According to the chemical formula La 2-x RE x Mg 17-y Ni y Dosing, where 0.2<x≤0.5, 1<y<3; RE is at least one of the rare earth elements neodymium, yttrium, and samarium; wherein, the magnesium and lanthanum in the chemical formula composition and the RE rare earth are in the ratio Increase the burning loss by 5%-15%, and the metal purity of raw materials is ≥99.5%;

[0033] 2. Put the prepared raw materials in the magnesia crucible, except for the magnesium on the top layer of the crucible, other materials are added to the crucible in no particular order. Melting by induction heating, vacuuming to 1×10 -2 ~5×10 -4Pa, and then filled with an inert protective gas of 0.01~0.1 MPa, that is, argon + helium mixed gas, the volume ratio of the mixed gas is about 1:1, or filled with high-purity helium; the melting temper...

Embodiment 1

[0039] Example 1: La 1.6 Nd 0.4 Mg 15 Ni 2 +100(wt)%Co+4(wt)%TiF 3 ;

Embodiment 2

[0040] Example 2: La 1.6 Y 0.4 Mg 15 Ni 2 +100(wt)%Co+6(wt)%TiF 3 ;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com