Recovery method and device for complete glass photovoltaic module

A technology for photovoltaic modules and recycling methods, applied in glass recycling, electronic waste recycling, recycling technology, etc., can solve the problems of high recycling rate, reducing separation difficulty, and low operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

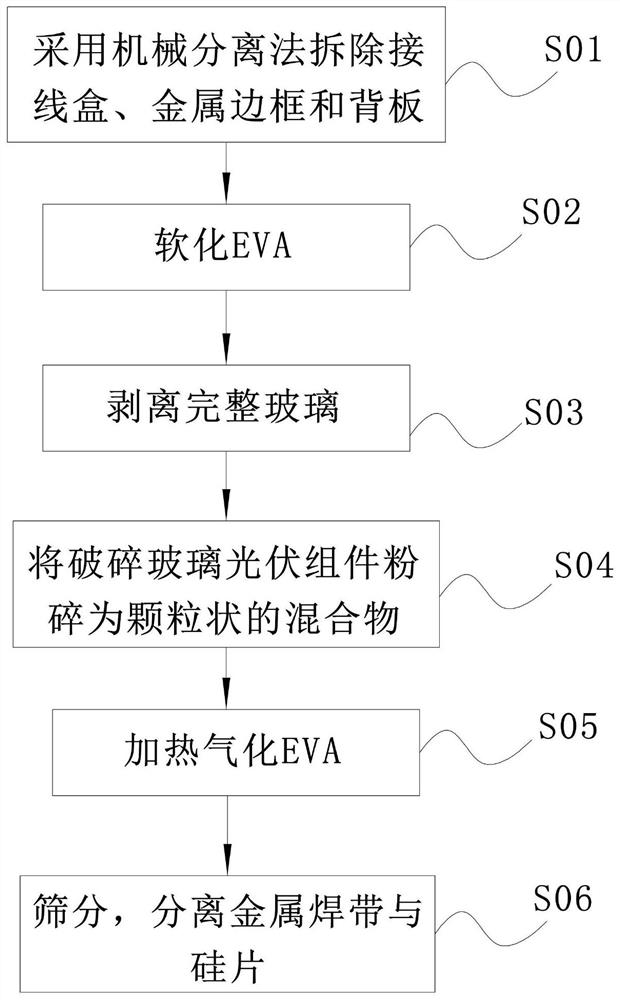

[0043] The method for recycling the complete glass photovoltaic module of the embodiment of the present invention can be used to recycle the photovoltaic module with relatively complete surface glass and no glass damage, and can recycle the whole piece of complete glass, avoiding the impact of glass crushing on the difficulty of the recycling process. see figure 1 , the recovery method of the complete glass photovoltaic module of this embodiment mainly includes:

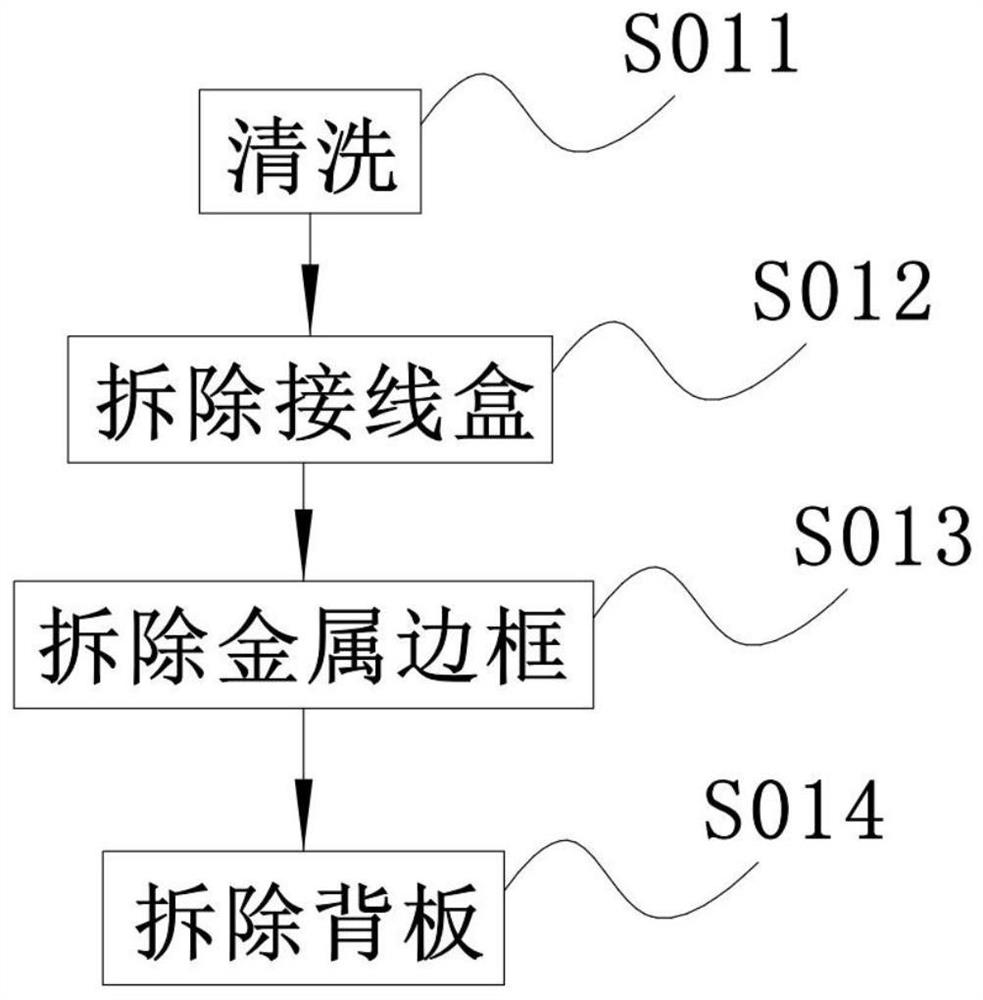

[0044] S01. Remove the junction box, metal frame and backplane by mechanical separation.

[0045] S02, heating and softening the EVA material.

[0046] S03. Peel off the complete glass on the surface of the complete glass photovoltaic module.

[0047] S04, crushing the photovoltaic module after peeling off the complete glass into a granular mixture.

[0048] S05. Heating the granular mixture to vaporize the EVA material, so that the silicon wafer and the metal ribbon are separated from each other.

[0049] S06, sie...

Embodiment 2

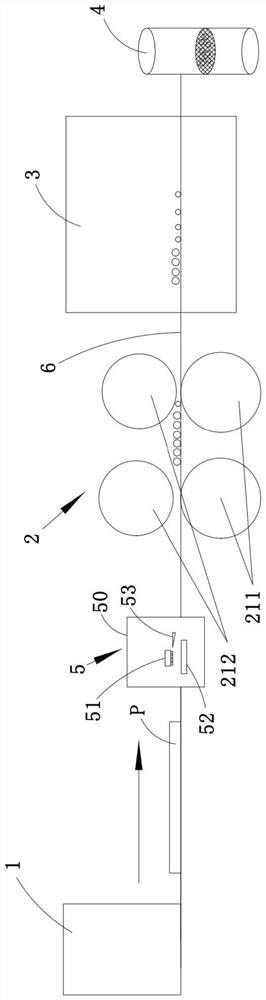

[0080] like image 3 As shown, the recovery device of the complete glass photovoltaic module in this embodiment mainly includes a mechanical separation chamber 1, a crushing mechanism 2, a heating chamber 3, a screening mechanism 4, a glass separation mechanism 5 and a transmission mechanism 6, wherein the transmission mechanism 6 is used as the whole The conveying part of the device is used to transfer materials among the mechanical separation chamber 1, the glass separation mechanism 5, the crushing mechanism 2, the heating chamber 3, and the screening mechanism 4. The mechanical separation chamber 1 is used to remove the junction box, The metal frame and back plate, the glass separation mechanism 5 is used to separate the complete glass on the surface of the photovoltaic module after removing the junction box, metal frame and back plate, including a preheating chamber 50 and a vacuum chuck assembly 51 located in the preheating chamber 50, The heating block 52, the heating b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com