Extrusion equipment and production process of conductive stainless steel plate lateral feeding type composite conductive track

A stainless steel plate, composite conductive technology, applied in metal extrusion dies, metal extrusion mandrels, etc., can solve the problems of complex extrusion equipment, increase production costs, poor electrical conductivity, etc., and achieve simple structure and cost of use. Low, tensile strength and mechanical strength improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

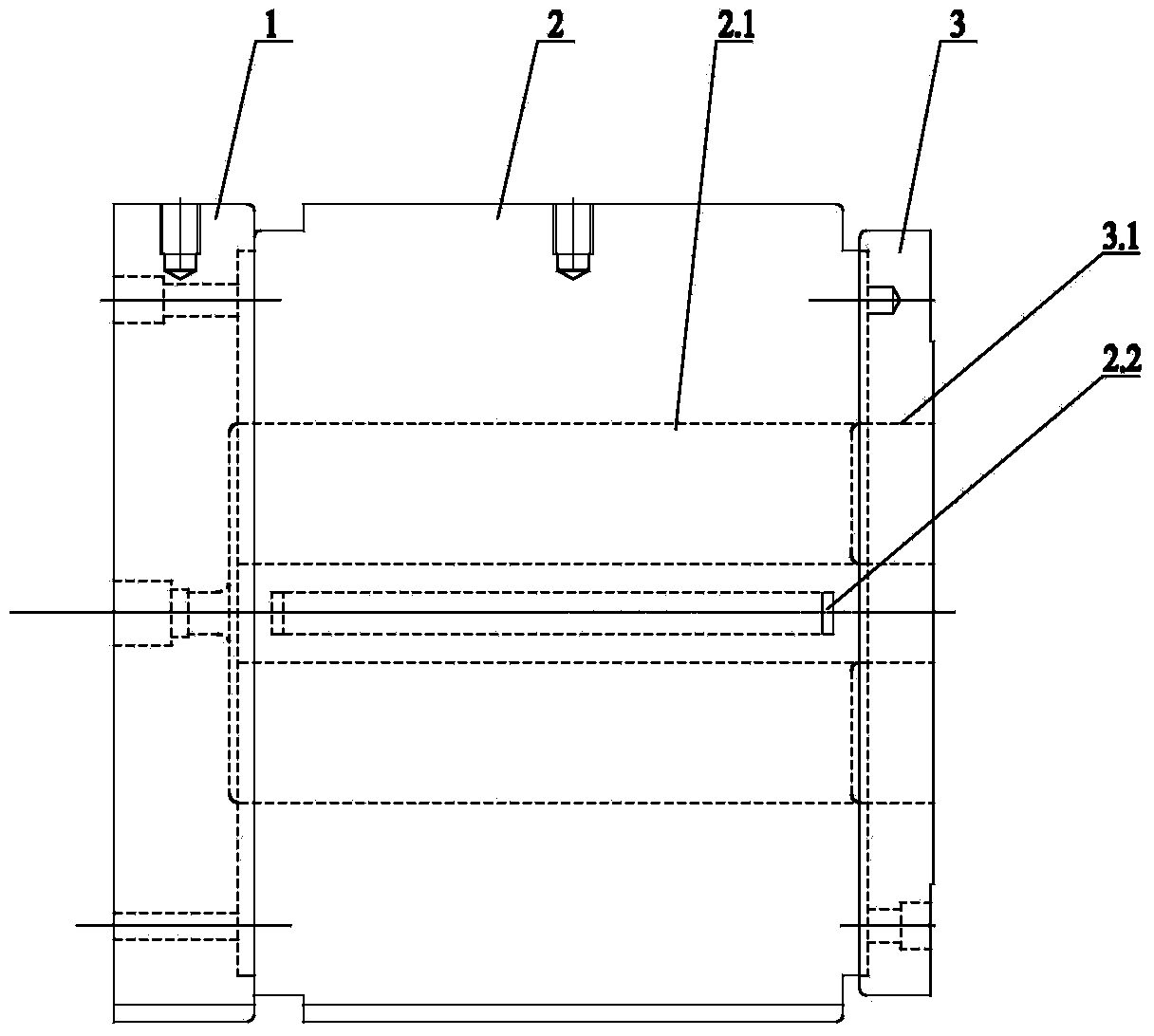

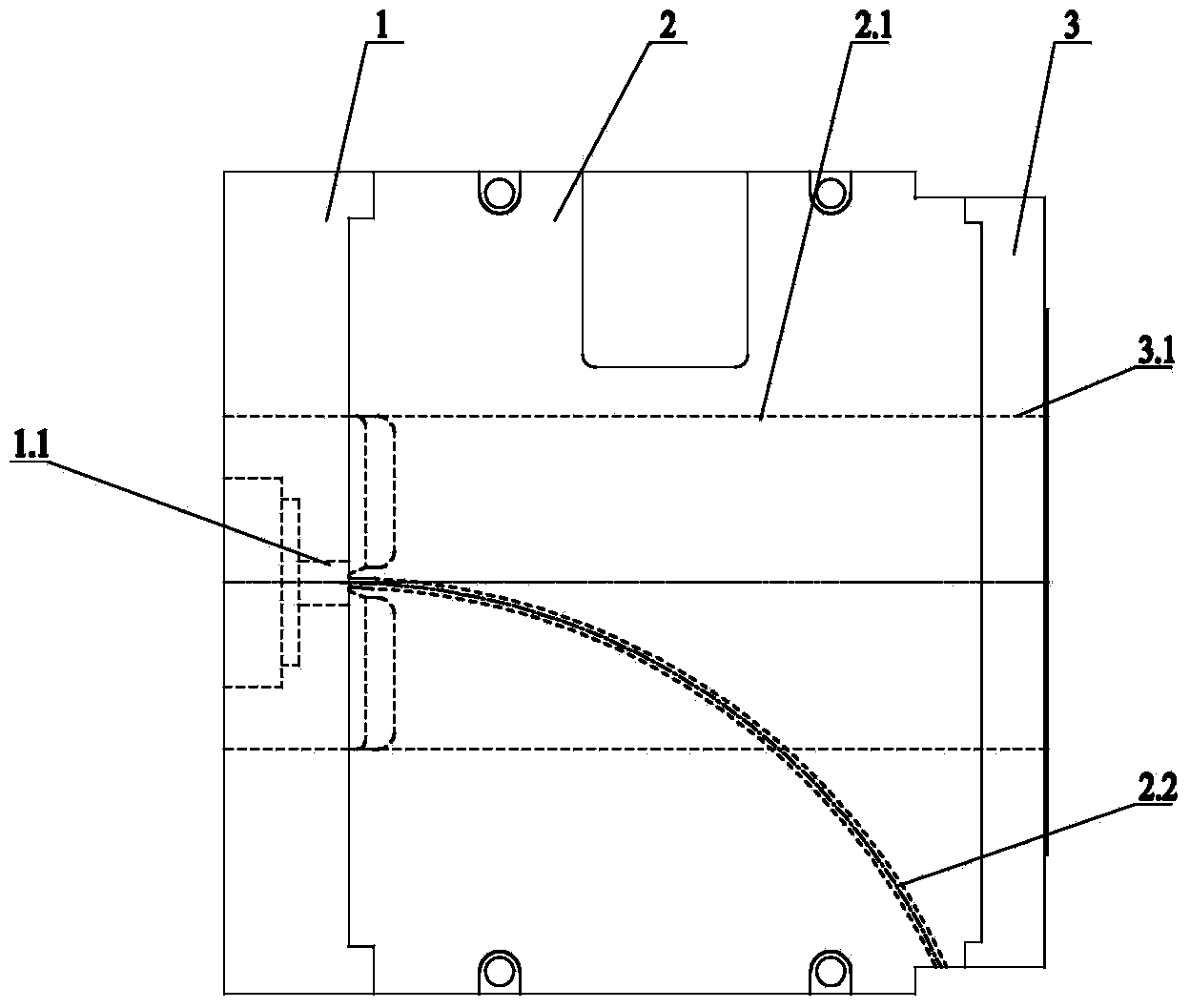

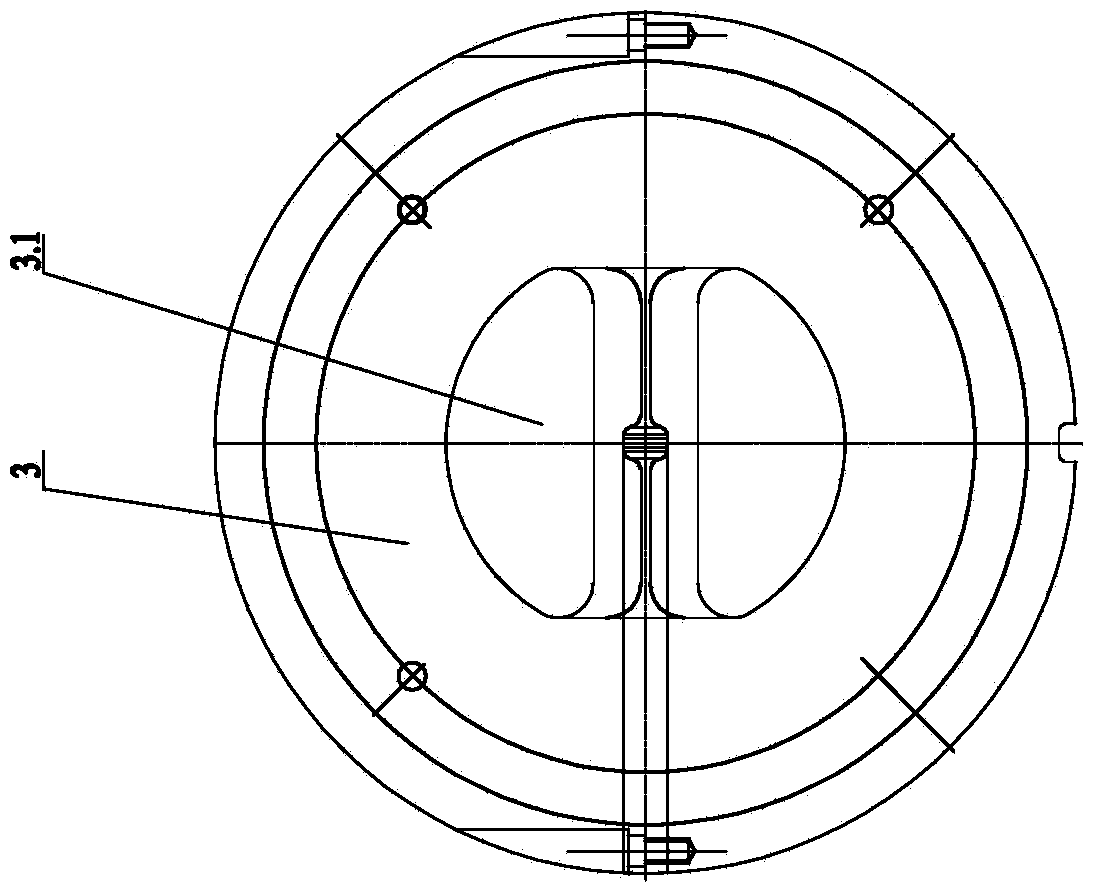

[0021] The extrusion equipment of the conductive stainless steel plate side feed type composite conductive track, it includes a forming template 1, a through die 2 and a feed plate die 3, the forming template 1 is fixed on the left end of the pass die 2, and the pass die 2 The right end face of the feed plate mold 3 is fixed; a conductive rail cavity 1.1 is provided on the forming template 1, and a base material feed channel 2.1 and a stainless steel plate feed channel 2.2 are opened on the through mold 2, and the stainless steel plate feeds The material channel 2.2 is an arc-shaped channel. The substrate feed channel 2.1 runs through the left end face and the right end face of the through die 2. The feed end of the stainless steel plate feed channel 2.2 is located on the front side wall of the pass die 2. The stainless steel plate feeds The discharge end of the channel 2.2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com