Film-aligning device for air cushion maker

a film alignment and air cushion maker technology, applied in the field of air cushion makers, can solve the problems of air cushion makers that are uneconomic and inconvenient to transport and store, defective inflating and sealing processes, and waste of manpower for air cushion makers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]While some preferred embodiments are provided hereinafter for illustrating the concept of the present invention as described above, it is to be understood that the components in these drawings are made for better explanation and need not to be made in scale. Besides, in the following description and the drawings, resemblances are indicated by the same numerals.

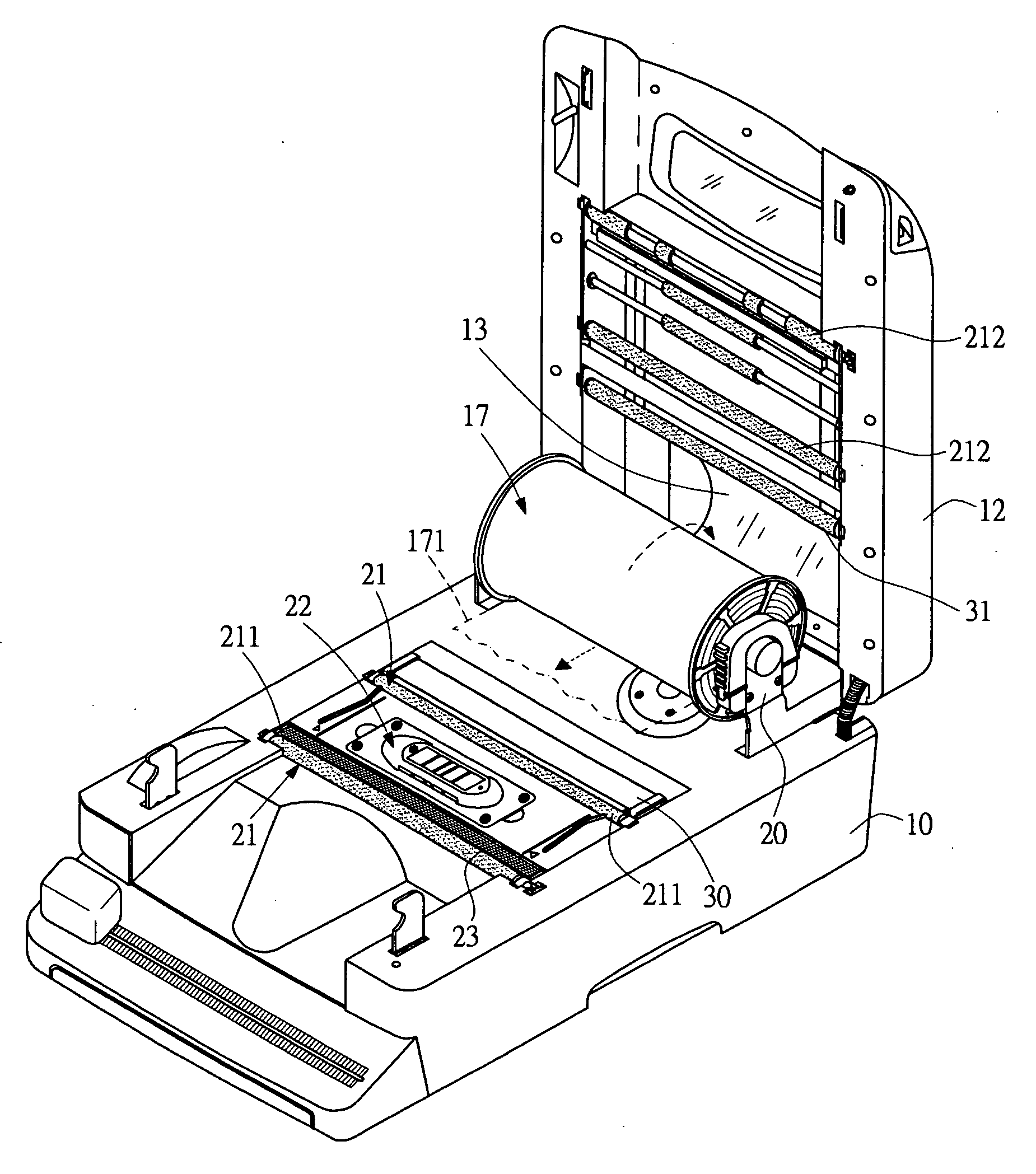

[0015]Referring to FIG. 3 for a perspective view of an air cushion maker according to the present invention. The air cushion maker primarily comprises a base 10 and a cover 12 that is liftably affixed to the base 10, wherein the cover 12 is now lying on the base 10. The cover 12 includes an arched canopy 13, a button switch 14, a plurality of function buttons 15 and a latch assembly 16 for holding the cover 12 with the base 10.

[0016]Another perspective view of the air cushion maker according to the present invention can be seen in FIG. 4 and 5, wherein the cover 12 is presently open. A film roll 17 to be inflated into an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com