Optical unit manufacturing method, optical unit, and forming apparatus

A technology of optical units and manufacturing methods, applied in optical elements, optical elements, optics, etc., can solve the problems of inability to withstand temperature, restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

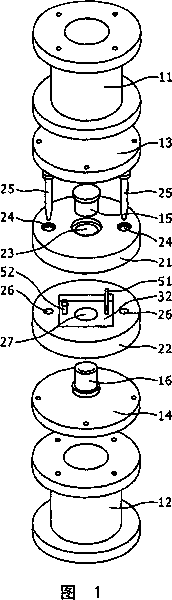

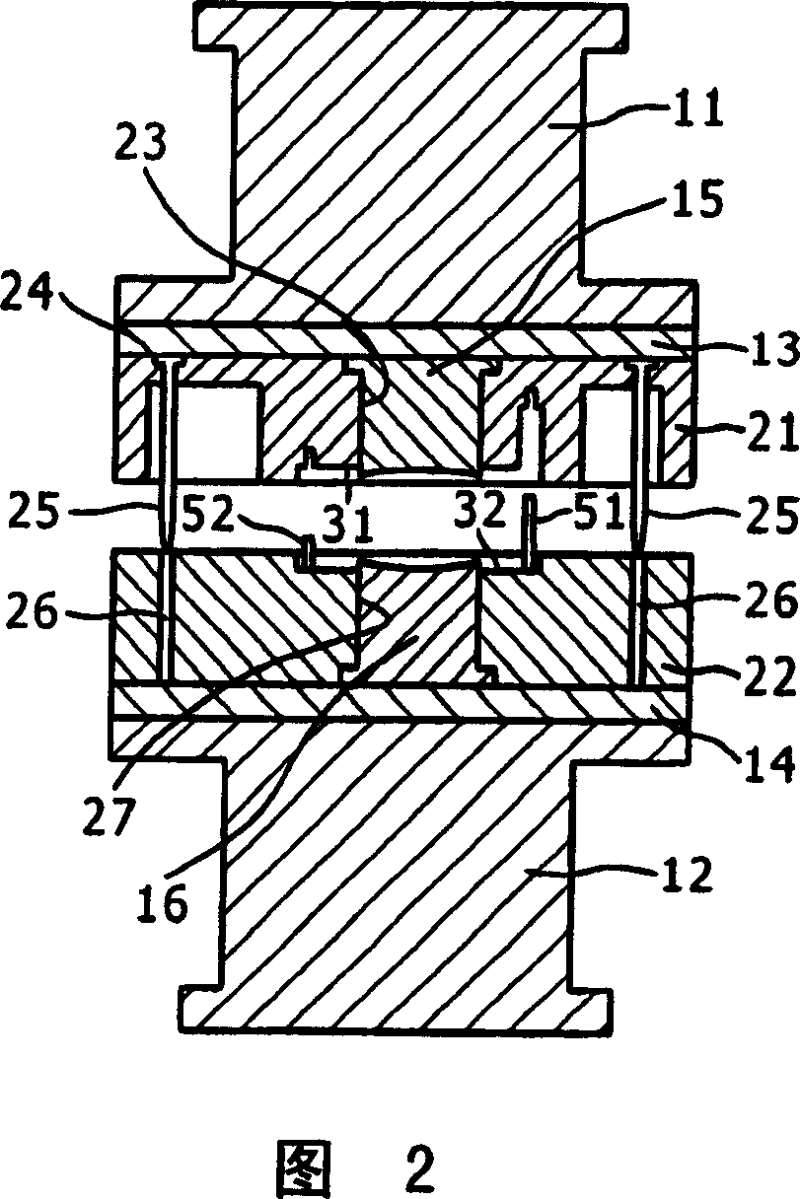

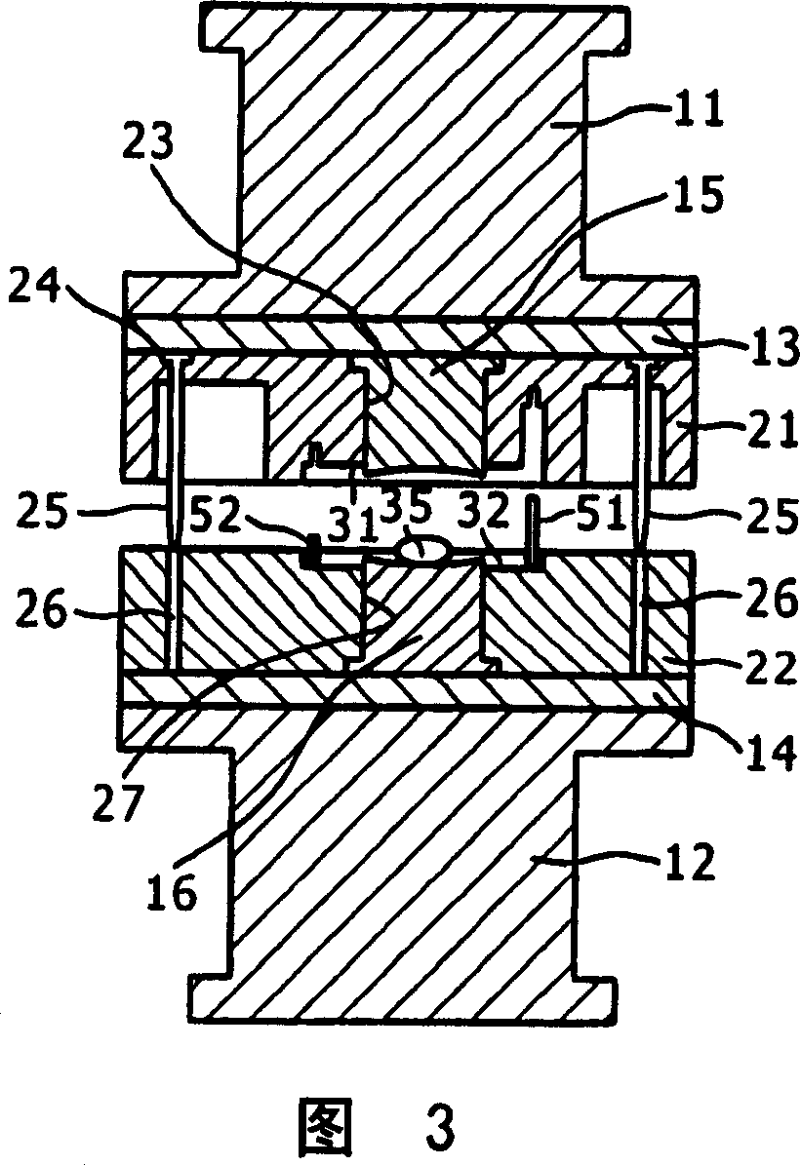

[0030] 1 and 2 illustrate a forming device for manufacturing an optical unit according to an embodiment of the present invention, and the shown forming device has an upper shaft 11 and a lower shaft 12 . The lower surface of the upper shaft 11 is provided with a template 13 , while the upper surface of the lower shaft 12 is provided with a template 14 . Furthermore, these templates 13 and 14 are adapted to hold the upper part 15 and the lower part 16 respectively.

[0031] The upper part 15 and the lower part 16 , both contained in the mold, are configured to be held by the upper and lower cylindrical parts 21 and 22 . The upper cylindrical part 21 has a circular central hole 23 in its central part, allowing the upper part 15 to be secured after it has been placed in the central hole 23 . The upper cylindrical member 21 also has a pair of insertion holes 24 which are arranged in a symmetrical configuration around the central hole 23 . A pair of positioning pins 25 inserted o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com