Matrix heat softening effect based high-efficiency high-precision milling technology of composite material

A thermal softening and milling technology, applied in milling machine equipment, manufacturing tools, details of milling machine equipment, etc., can solve the problems of difficult to achieve high machining accuracy requirements, low machining efficiency, tool wear and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

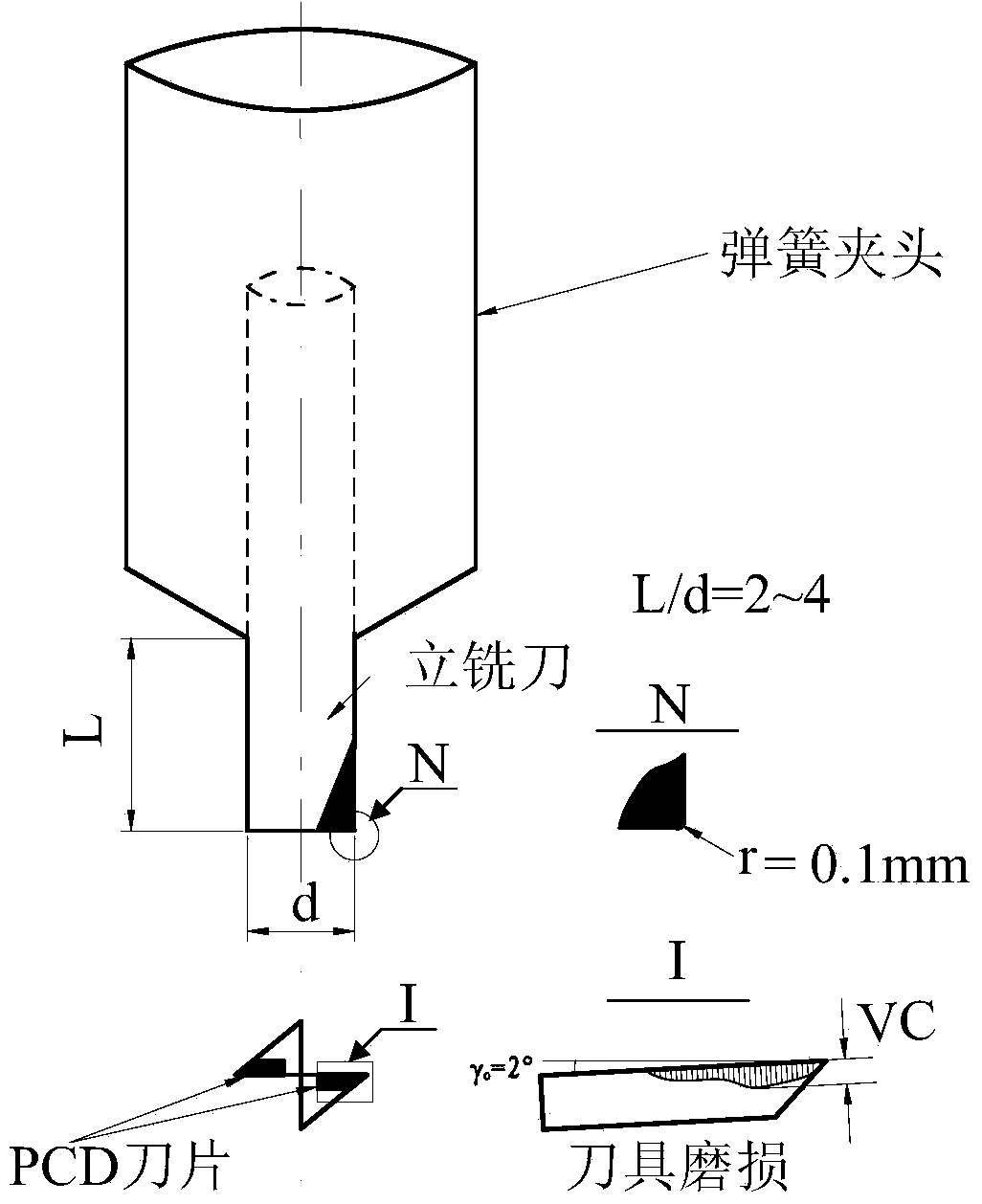

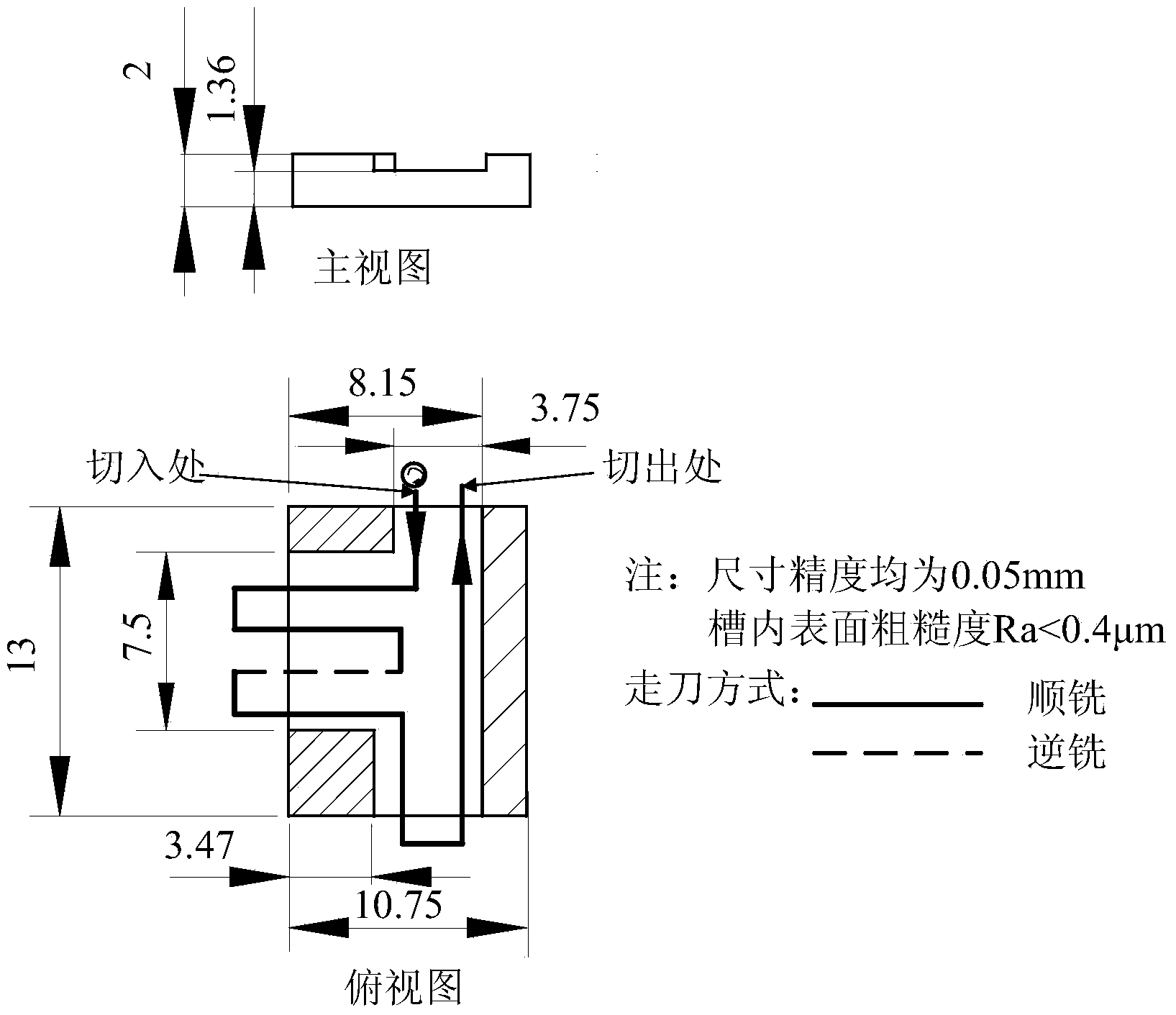

[0007] to attach figure 2 The processing of a typical part of an aluminum matrix composite material with a SiC volume fraction of 65% is taken as an example. The complete processing process is divided into two steps: rough milling and fine milling. The tool used is a PCD tool with a particle size of 10 μm. The blunting standard of the tool is VC=0.6mm. The overhang length L of the rough / finishing tool is 3 times the tool diameter d. The end surface of the tool is shown in the attached figure 1 shown. The specific implementation process is as follows:

[0008] 1. Install the end mill on the corresponding tool position of the CNC milling machine, and install the 2mm thick cuboid workpiece on the milling machine table.

[0009] 2. The position of the workpiece is measured by the contact positioning probe of the CNC milling machine, and the coordinates of the workpiece center are obtained, and then the tool cutting coordinate point and the circular tool path are determined acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com