High-strength and high-resiliency spandex fiber and preparation method thereof

A technology of spandex fiber and high resilience, applied in the field of polymer chemistry, can solve the problems of decreased storage stability of spandex stock solution, limited improvement of spandex resilience, and decreased spinning performance, so as to ensure storage stability and spinning performance. Stability, good storage stability, the effect of improving weaving properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

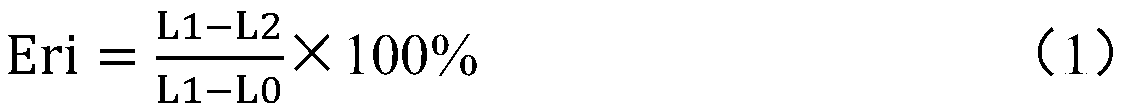

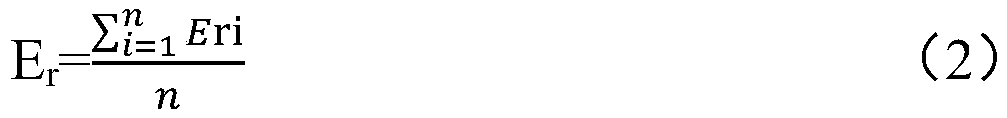

[0026] The preparation method of the spandex fiber in this example comprises the following steps: mixing 4,4'-diphenylmethane diisocyanate and 1% 2,4'-diphenylmethane diisocyanate in a molar ratio of 99% respectively to obtain diisocyanate , according to carbodiimide-modified 4,4'-diphenylmethane diisocyanate (CD-MDI produced by Wanhua Chemical in this example) with a mass ratio of 5wt% and the above-mentioned diisocyanate with a mass ratio of 95wt%. The mixture is manufactured as a mixed isocyanate.

[0027] According to the capping ratio (CR) of 1.65, the polytetramethylene ether glycol with an average molecular weight of 1800 is mixed with the above-mentioned mixed isocyanate, mixed at 45°C for 1.5 hours, and kept for 1.5 hours when the temperature reaches 90°C. , and then cooled at 40° C. for 1.5 hours to prepare a prepolymer. A mixture of ethylenediamine and 10% 1,2-propylenediamine in a molar ratio is used as a chain extender, diethylamine is used as a chain terminator,...

Embodiment 2

[0030] The difference between the preparation method of the spandex fiber in this example and Example 1 is that the molar ratios are respectively 97% of 4,4'-diphenylmethane diisocyanate and 3% of 2,4'-diphenylmethane diisocyanate The isocyanate is mixed to obtain diisocyanate, and then the mixture obtained by carbodiimide-modified diisocyanate with a mass ratio of 5 wt% and the above-mentioned diisocyanate with a mass ratio of 95 wt% is produced as a mixed isocyanate. All the other raw materials, reaction steps and experimental conditions are the same as in Example 1.

Embodiment 3

[0032] The difference between the preparation method of the spandex fiber in this example and Example 1 is that the molar ratios are respectively 95% of 4,4'-diphenylmethane diisocyanate and 5% of 2,4'-diphenylmethane diisocyanate The isocyanate is mixed to obtain diisocyanate, and then the mixture obtained by carbodiimide-modified diisocyanate with a mass ratio of 5 wt% and the above-mentioned diisocyanate with a mass ratio of 95 wt% is produced as a mixed isocyanate. All the other raw materials, reaction steps and experimental conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com